Novel method for synthesizing SBQ sensitizer

A synthesis method and sensitizer technology, which is applied in the field of synthesis of new SBQ sensitizer, can solve the problems of increased loss, inapplicability to industrial production, and difficult drying of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] 1. Experimental reagents and raw materials

[0050] Methanol, analytically pure, Shanghai No. 1 Zhenxing Chemical Factory;

[0051] Ethanol, analytically pure, Shanghai Pilot Chemical Corporation;

[0052] 36% concentrated hydrochloric acid, analytically pure, Shanghai No. 2 Zhenxing Chemical Factory;

[0053] Sodium hydroxide, analytically pure, Xilong Chemical Factory, Shantou City, Guangdong;

[0054] Carbon tetrachloride, analytically pure, Shanghai Chemical Reagent Co., Ltd.;

[0055] Tetrahydrofuran, analytically pure, Tianjin BASF Chemical Co., Ltd.;

[0056] Triphenylphosphine, chemically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0057] Terephthalaldehyde, chemically pure, Sinopharm Chemical Reagent Co., Ltd.;

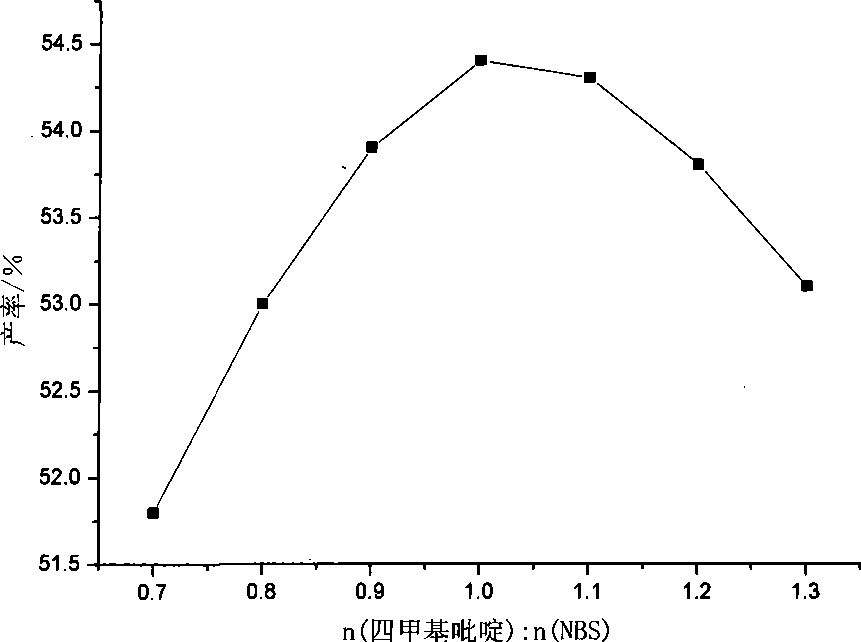

[0058] Tetramethylpyridine, analytically pure, Shanghai Kefeng Chemical Reagent Co., Ltd.;

[0059] N-bromosuccinimide, analytically pure, Sinopharm Chemical Reagent Co., Ltd.

[0060] 2. Reagent handling

[0061] Tetrahydrofuran (THF): Use L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com