A kind of whole grain highland barley gluten and preparation method thereof

A technology of highland barley noodles and whole grains, applied in the field of whole grain highland barley gluten and its preparation, to achieve good film-forming properties, prevent aging, and inhibit the rise of blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

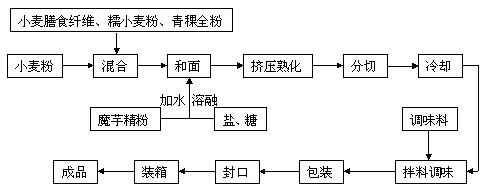

[0052] see figure 1 , a kind of preparation method of whole grain highland barley gluten is characterized in that, comprises the following steps:

[0053] 1) Mixing: Pour wheat flour, wheat dietary fiber powder, waxy wheat flour and highland barley powder into the mixer, cover the sealing cover of the mixer, start the stirring switch and stir for more than 5 seconds; the purpose is to compact the flour and prevent the water from flowing out after adding water. Oozing out at the outlet, and taking into account work efficiency and energy saving, preferably, the mixing and stirring time described in step 1) is 5-10s.

[0054] 2) Kneading noodles: Weigh konjac powder, salt, and sweeteners according to the formula, add them to the water, stir until they are evenly dissolved, then pour them into the mixer, cover the sealing cover, and start the switch to stir for more than 10 seconds. , open the discharge port, and discharge the mixed powder; in the production process, the function...

Embodiment 1

[0063] A whole grain highland barley gluten, the composition of which comprises wheat flour, wheat dietary fiber powder, waxy wheat flour, konjac powder, whole highland barley flour, salt, sweetener, water, and the above components are respectively in terms of mass fraction: wheat meal Fiber powder 2%, waxy wheat flour 9%, konjac fine flour 0.3%, highland barley flour 4%, salt 4%, sweetener 4%, water 20%, the balance medium gluten wheat flour. The sweetener is a combination of steviol glycoside and mogroside.

[0064] see figure 1 , the preparation method of above-mentioned whole grain highland barley gluten, comprises the following steps:

[0065] 1) Mixing: Pour 5.67kg of wheat flour, 0.2kg of wheat dietary fiber powder, 0.9kg of waxy wheat flour and 0.4kg of highland barley flour into the mixer, cover the sealing cover of the mixer, turn on the stirring switch and stir for 5 seconds;

[0066] 2) Kneading noodles: Weigh 0.03kg of konjac powder, 0.4kg of salt, and 0.4kg of ...

Embodiment 2

[0073] A whole grain highland barley gluten, the composition of which comprises wheat flour, wheat dietary fiber powder, waxy wheat flour, konjac powder, whole highland barley flour, salt, sweetener, water, and the above components are respectively in terms of mass fraction: wheat meal Fiber powder 6%, waxy wheat flour 3%, konjac fine flour 0.9%, highland barley flour 20%, salt 5%, sweetener 4.5%, water 25%, the balance medium gluten wheat flour. The sweetener is a mixture of white granulated sugar, steviol glycoside, mogroside and thaumatin.

[0074] see figure 1 , the preparation method of above-mentioned whole grain highland barley gluten, comprises the following steps:

[0075] 1) Mixing: Pour 3.56kg of wheat flour, 0.6kg of wheat dietary fiber powder, 0.3kg of waxy wheat flour and 2kg of highland barley flour into the mixer, cover the sealing cover of the mixer, start the stirring switch and stir for 15s;

[0076] 2) Kneading noodles: Weigh 0.09kg of konjac powder, 0.5k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com