Functional plant fermented beverage and preparation method thereof

A plant fermentation and functional technology, applied in the field of food manufacturing, can solve the problems of unwell diabetics, not suitable for direct consumption, high mucopolysaccharides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of liquid functional plant fermented beverage

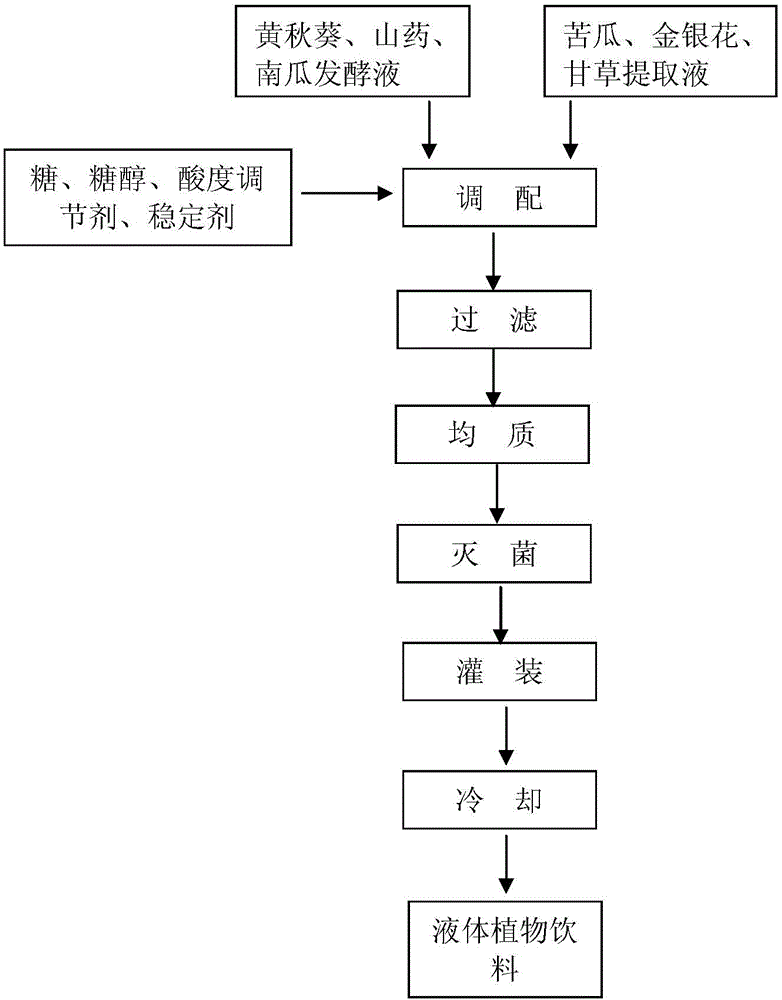

[0036] Such as figure 1 As shown, it is a schematic flow chart of the preparation method of the liquid functional plant fermented beverage provided by an embodiment of the present invention.

[0037] Step 1, pretreat fresh okra, yam and pumpkin, wherein 30 kg of okra, 30 kg of yam and 40 kg of pumpkin. The yam and pumpkin are peeled and washed; the okra is washed; then beating, and the slurry is passed through a 20-mesh sieve. Heat the slurry to 90°C, keep it warm for 5 minutes, cool down to 55°C, and adjust the pH value to 5.2 with citric acid in an enzymolysis tank to obtain 80 kg of pretreated product.

[0038] Weigh 20 grams of pectinase and 20 grams of cellulase with an activity greater than 20000u / mL, mix them together, dilute them with 200 mL of pure water, add them to the enzymatic hydrolysis tank, stir evenly, record the enzymatic hydrolysis time, and keep the temperature at 60°C. Enzy...

Embodiment 2

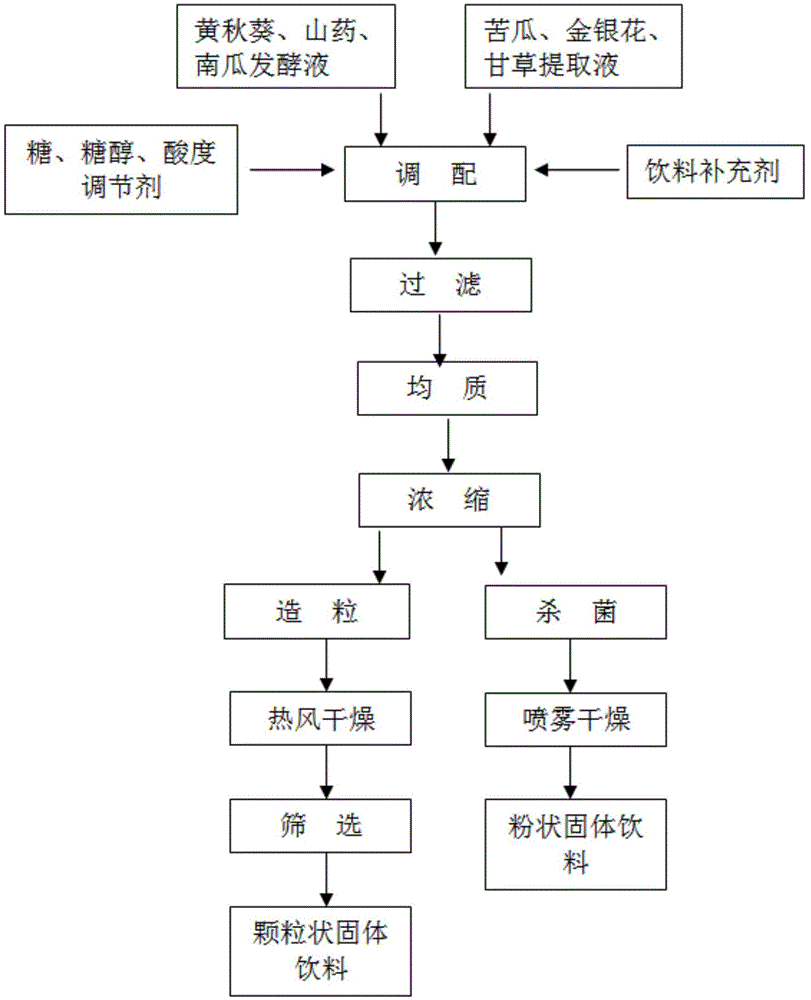

[0055] Embodiment 2: prepare powdery solid functional plant fermented beverage

[0056] Such as figure 2 As shown, it is a schematic flow chart of the preparation method of the powdery solid functional plant fermented beverage provided by the embodiment of the present invention.

[0057] Step 1, pretreat fresh okra, yam and pumpkin, wherein 30 kg of okra, 20 kg of yam, and 30 kg of pumpkin. The yam and pumpkin are peeled and washed; the okra is washed; then beating, and the slurry is passed through a 20-mesh sieve. Heat the slurry to 90°C, keep it warm for 5 minutes, cool down to 55°C, and adjust the pH value to 5.2 with citric acid in an enzymolysis tank to obtain 60 kg of pretreated product.

[0058]Weigh 10 grams of pectinase and 10 grams of cellulase with an activity greater than 20000u / mL, mix them together, dilute them with 200 mL of pure water, add them to the enzymatic hydrolysis tank, stir evenly, record the enzymatic hydrolysis time, and keep the temperature at 60...

Embodiment 3

[0080] Embodiment 3: preparation granular solid functional plant fermented beverage

[0081] Such as figure 2 As shown, it is a schematic flow chart of the preparation method of the granular solid functional plant fermented beverage provided by an embodiment of the present invention.

[0082] Step 1, pretreat fresh okra, yam and pumpkin, wherein 30 kg of okra, 25 kg of yam, and 20 kg of pumpkin. The yam and pumpkin are peeled and washed; the okra is washed; then beating, and the slurry is passed through a 20-mesh sieve. Heat the slurry to 90°C, keep it warm for 5 minutes, cool down to 55°C, and adjust the pH value to 5.2 with citric acid in an enzymolysis tank to obtain 60 kg of pretreated product.

[0083] Weigh 20 grams of pectinase and 20 grams of cellulase with an activity greater than 20000u / mL, mix them together, dilute them with 200 mL of pure water, add them to the enzymatic hydrolysis tank, stir evenly, record the enzymatic hydrolysis time, and keep the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total number of colonies | aaaaa | aaaaa |

| Total number of colonies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com