Cold-fever-treating granules and preparation method thereof

A technology for removing impurities in Ganmaotupyre granule and its preparation, which can solve the problems of unsatisfactory drug efficacy, shock in patients, and large side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

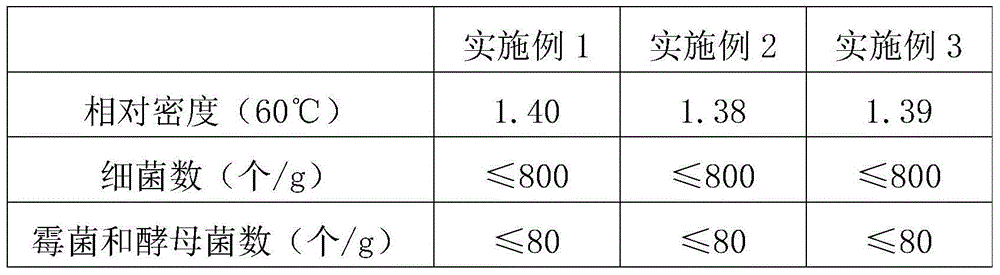

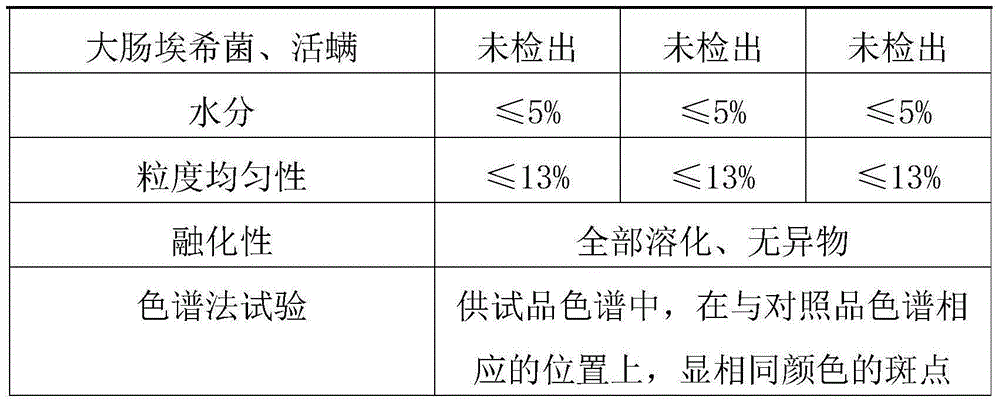

Examples

Embodiment 1

[0039] A preparation process of Ganmao antipyretic granule is as follows:

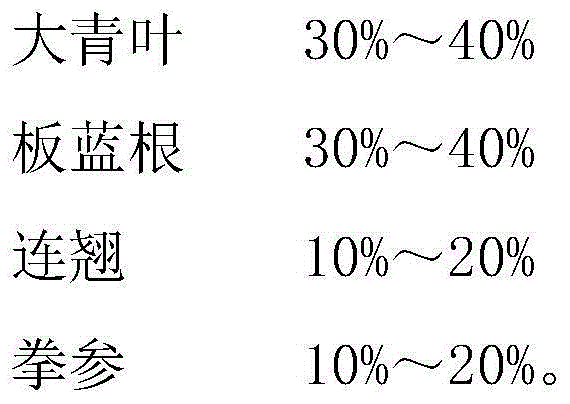

[0040] ①. Finishing and processing process: remove impurities from 400g Folium Isatidis, wash slightly, cut into 8-10cm wide slices, dry, and the water content does not exceed 13%; remove impurities from 400g Radix Radix, rinse, moisten, cut into 1.3-1.5cm section, dry at 65°C, the water content does not exceed 15%; remove impurities from 200g of forsythia, and the water content does not exceed 10%; Cut into 1.3-1.5cm sections, dry at 65°C, and the water content should not exceed 15%;

[0041] ②. Decoction: Mix the four medicinal materials processed in step ①, add 10 times the amount of water to decoct twice, each time for 3 hours, control the decoction temperature at 95-100°C, pressure at 0.15-0.2MPa, The liquid output is 4 to 4.5 times of the total amount of medicinal materials, the decoction is combined, filtered, and transferred to a storage tank;

[0042] ③. Transfer the decoction in the storage...

Embodiment 2

[0053] A preparation process of Ganmao antipyretic granule is as follows:

[0054] ①. Finishing and processing process: remove impurities from 300g Folium Isatidis, wash slightly, cut into 7-9cm wide slices, dry, and the moisture does not exceed 13%; remove impurities from 300g Radix Radix, rinse, moisten, cut into pieces 1.1-1.3cm section, dry at 65°C, moisture not exceeding 15%; remove impurities from 120g forsythia, moisture not exceeding 10%; remove impurities from 100g ginseng, wash with water to clean the sediment, moisten thoroughly, cut into pieces Form into 1.2-1.5cm sections, dry at 65°C, and the water content should not exceed 15%;

[0055] ②. Decoction: Mix the four medicinal materials processed in step ①, add 6 times the amount of water to decoct twice, each time for 2 hours, control the decoction temperature at 95-100°C, pressure at 0.2-0.3MPa, The liquid output is 4 to 5 times of the total amount of medicinal materials, the decoction is combined, filtered, and ...

Embodiment 3

[0063] A preparation process of Ganmao antipyretic granule is as follows:

[0064] ①. Finishing and processing process: remove impurities from 330g Folium Isatidis, wash slightly, cut into 7-10cm wide slices, dry, and the water content does not exceed 13%; remove impurities from 350g Radix Radix, rinse, moisten, cut into 1.2-1.5cm section, dry at 65°C, moisture not exceeding 15%; remove impurities from 140g forsythia, moisture not exceeding 10%; remove impurities from 160g fist ginseng, wash with water and sand, moisten thoroughly, cut Cut into 1.1-1.4cm sections, dry at 65°C, and keep the water content not exceeding 15%;

[0065] ②. Decoction: Mix the four medicinal materials processed in step ①, add 8 times the amount of water to decoct twice, each time for 1.5 hours, control the decoction temperature at 95-100°C, pressure at 0.15-0.25MPa, The liquid output is 4 to 5 times of the total amount of medicinal materials, the decoction is combined, filtered, and transferred to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com