Dual-driving lifting type transmission system of thickener

A transmission system and dual-drive technology, applied in the field of thickeners, can solve the problems of damage to the transmission device, twisted scraper shaft and rake arm, and high concentration of underflow at the bottom, so as to ensure safety and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

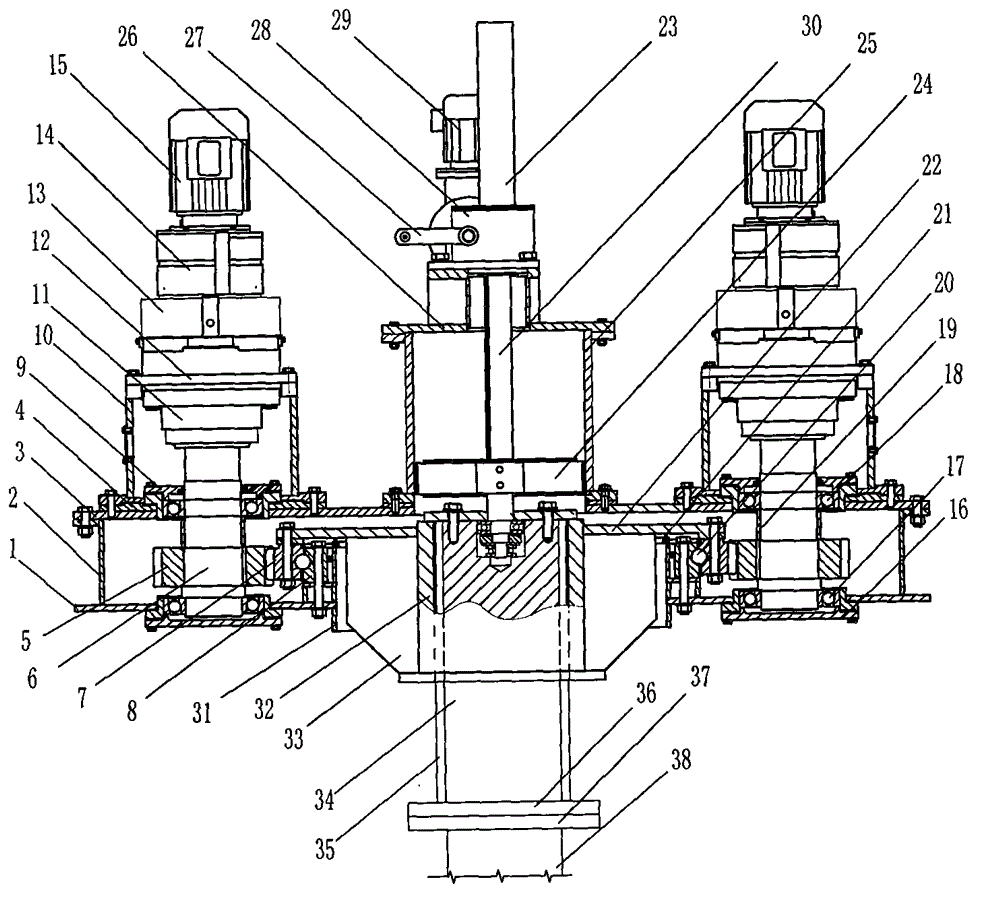

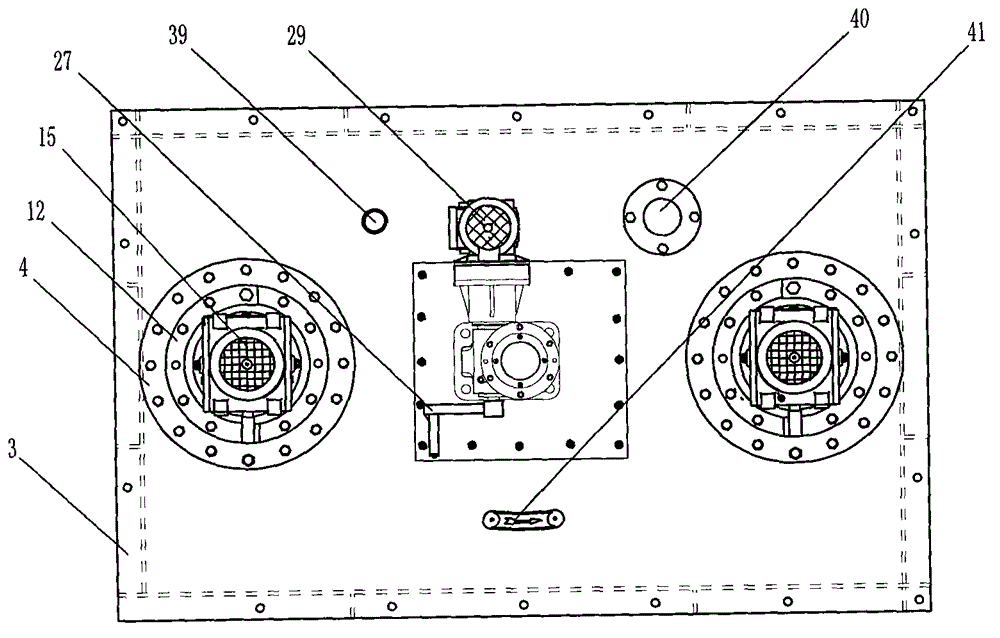

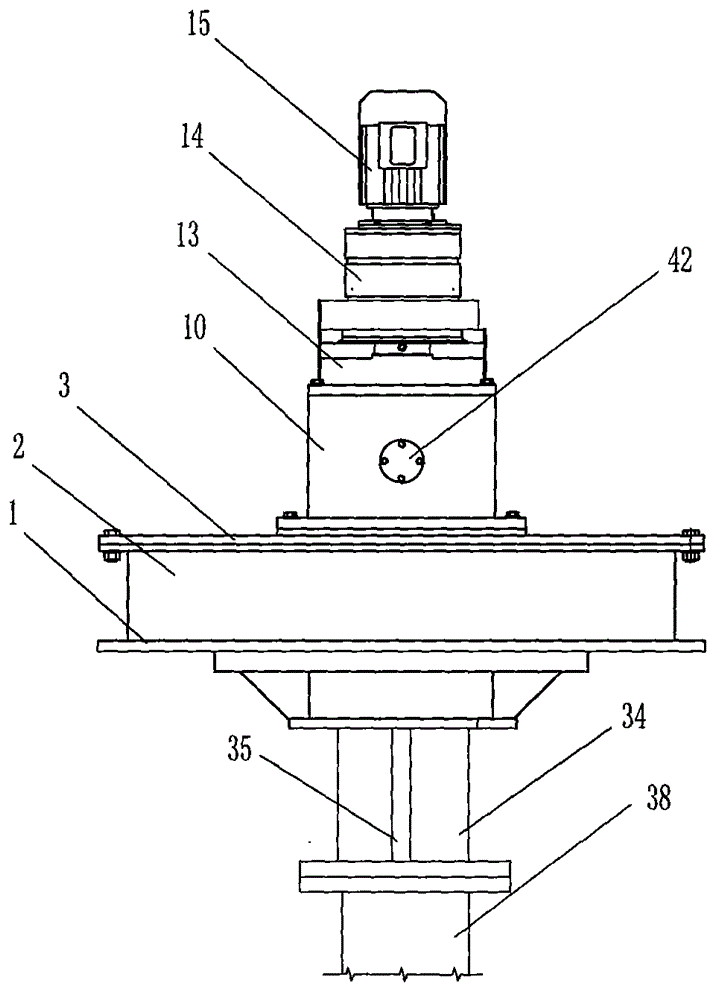

[0019] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a dual-drive lifting transmission system for a thickener, which can be divided into five parts: the box part, the double drive part, the rotating part, the lifting part and the electrical control part, the box part, The box part is provided with a box bottom plate 1, and the outer box body plate 2 and the inner box body plate 31 are welded on the box body bottom plate 1, and the upper splint and the lower splint are welded on the inner box body plate 31. The upper splint is welded, the upper splint is provided with a polytetrafluoroethylene seal 21 to connect the large disc 22, the inner lining block 8 is installed with bolts in the upper splint and the lower splint, and the inner lining block 8 is provided with a rolling round steel ball 20 and a large gear 7 connection, the upper cover plate 3 is installed on the box body with bolts, the bracket 10 is set to weld the base 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com