Magnesium-aluminum-carbon composite support sulfur-tolerant shift catalyst and preparation method thereof

A technology for sulfur-resistant conversion and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems affecting catalytic activity and stability, and carrier phase structure Changes, anti-sulfurization active components and other issues, to achieve good economic benefits, low production cost, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

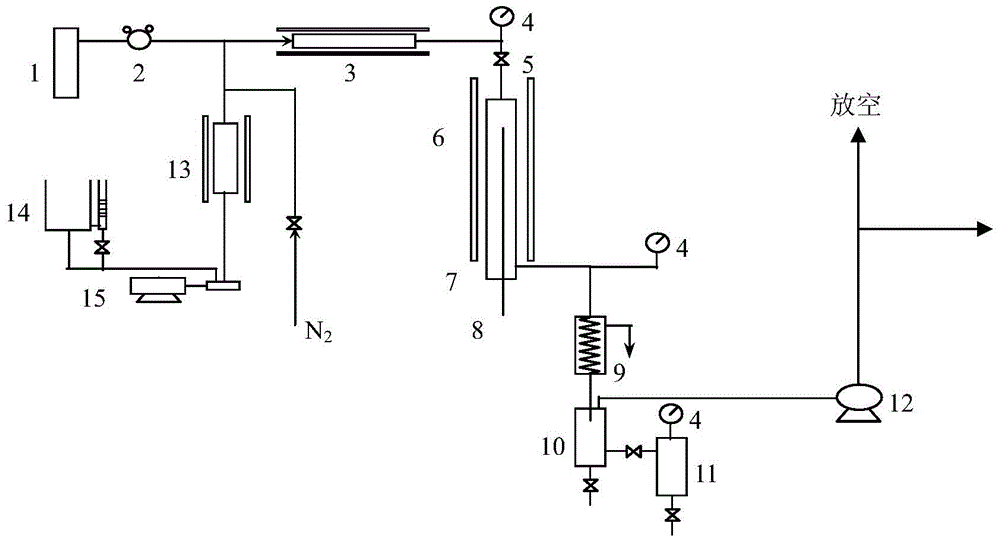

Image

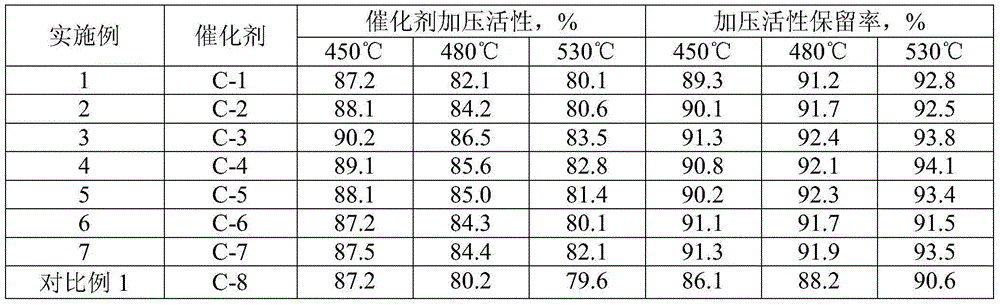

Examples

Embodiment 1

[0048] First, the industrial furfural slag is roasted at 70°C for 5 hours, and then crushed through a 120-mesh sieve to obtain pretreated furfural slag. Dissolve 8.6g of ammonium molybdate with 45.0mL of deionized water to obtain solution A containing molybdenum; dissolve 15.5g of cobalt nitrate with 100.0mL of deionized water; then add 8.0g of citric acid into the above solution, stir and dissolve to obtain Solution B containing cobalt.

[0049] Weigh 129.9g of pretreated furfural slag, 8.2g of magnesia, 29.8g of pseudoboehmite, 3.0g of Tianqing powder and mix evenly, add solution A, knead evenly; then add solution B, knead, shape, and let it dry naturally Dry, then roast. The heating process adopts a gradient heating method, from 20°C to 200°C over 1 hour, and then keep the temperature at 200°C for 1 hour; then raise the temperature to 550°C over 1 hour, roast for 3 hours, and then cool down naturally to room temperature to obtain the sulfur-tolerant shift catalyst C-1 . ...

Embodiment 2

[0051] First, the industrial furfural slag is roasted at 65°C for 7 hours, and then crushed through a 120-mesh sieve to obtain pretreated furfural slag. Dissolve 12.3g of ammonium molybdate in 50.0mL of deionized water to obtain ammonium molybdate solution A; dissolve 19.4g of cobalt nitrate in 100.0mL of deionized water, then add 5.0g of citric acid into the above cobalt nitrate solution, stir to dissolve , to obtain solution B containing cobalt.

[0052] Weigh 151.5g of pretreated furfural slag, 15.6g of magnesium oxalate, 15.4g of pseudoboehmite, and 3.0g of starch and mix evenly, add solution A, and knead evenly; then add solution B, knead, shape, and dry naturally. Re-roast. The heating process adopts a gradient heating method, from 20°C to 200°C over 1 hour, and at 200°C for 1 hour at a constant temperature; then after 1 hour, the temperature is raised to 530°C, calcined for 3 hours, and naturally lowered to room temperature to obtain the sulfur-tolerant shift catalyst ...

Embodiment 3

[0054] First, the industrial furfural slag is roasted at 70°C for 5 hours, and then crushed through a 120-mesh sieve to obtain pretreated furfural slag. Dissolve 11.0g of ammonium molybdate in 40.0mL of deionized water to obtain ammonium molybdate solution A; dissolve 11.7g of cobalt nitrate in 50.0mL of deionized water, then add 3.0g of citric acid into the above cobalt nitrate solution, stir to dissolve , to obtain solution B containing cobalt.

[0055] Weigh 108.2g of pretreated furfural slag, 38.8g of magnesium acetate, 39.0g of pseudo-boehmite, 4.0g of sucrose and mix evenly, add solution A, knead evenly; then add solution B, knead, shape, and dry naturally. Re-roast. The heating process adopts a gradient heating method, from 20°C to 200°C in 1 hour, and then keep the temperature at 200°C for 1 hour; then raise the temperature to 550°C in 1 hour, roast for 2 hours, and then cool down to room temperature naturally to obtain the sulfur-tolerant shift catalyst C-3 . The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com