Macropore adsorption resin as well as preparation method and application thereof

A technology of pore adsorption and resin, which is applied in the field of polymer chemistry and can solve problems such as not being suitable for large-scale production, failing to meet requirements, and the amount of resin adsorption is not large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

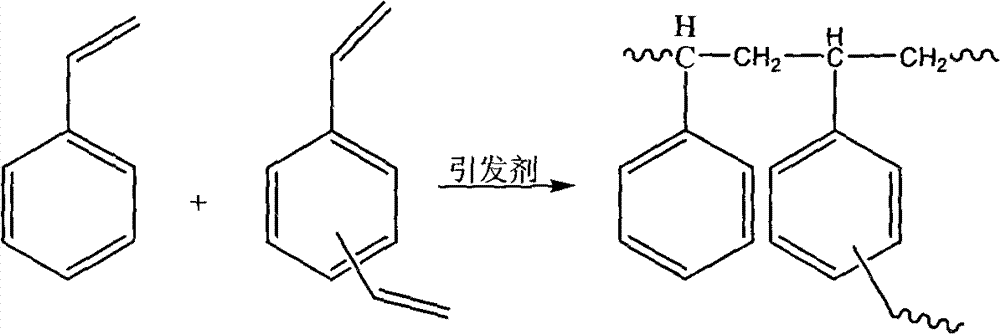

[0036] Embodiment 1: the preparation of macroporous polystyrene resin

[0037] Add 1500ml of purified water into a 3000ml reactor equipped with a thermometer, condensing reflux device and stirring, add 15g of gelatin while stirring, raise the temperature to 55°C, after the gelatin is completely dissolved, add 200g of styrene, 300g of Divinylbenzene (content is 55.7%), 200g 200 # The mixture composed of gasoline, 2.5g benzoyl peroxide, etc. After the organic mixture forms uniform droplets of a certain size in the dispersion medium solution, the temperature is raised to 75°C, polymerized for 3 hours, heated to 80°C for 7 hours, and then heated to 85°C ℃, continue curing for 6 hours and then stop the reaction. Rinse with a lot of water, sieve, control the particle size between 20-70 mesh, then put the sphere into a Soxhlet extractor, extract with acetone for 12 hours to remove the porogen, and finally wash the acetone in the sphere with water Clean and dry to get white balls of...

Embodiment 2

[0038] Embodiment 2: the preparation of macroporous polystyrene resin

[0039] The proportioning ratio is: 200g styrene, 36g divinylbenzene (55.7% content), 470g toluene and 2.35g benzoyl peroxide, and refer to Example 1 for the remaining operations.

Embodiment 3

[0040] Embodiment 3: the preparation of terephthaloyl chloride

[0041]Add 166g of terephthalic acid into a reaction flask containing 120g of ethylene dichloride, add thionyl chloride and stir evenly, reflux at 80°C for 6 hours, then distill out thionyl chloride and ethylene dichloride under reduced pressure, namely To get terephthaloyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com