Preparation method of FCC gasoline desulfurization agent composition

A technology for catalytic cracking gasoline and desulfurization catalysts, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of poor component uniformity and small specific surface area, and achieve lower calcination temperature, large pore volume, and saving The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

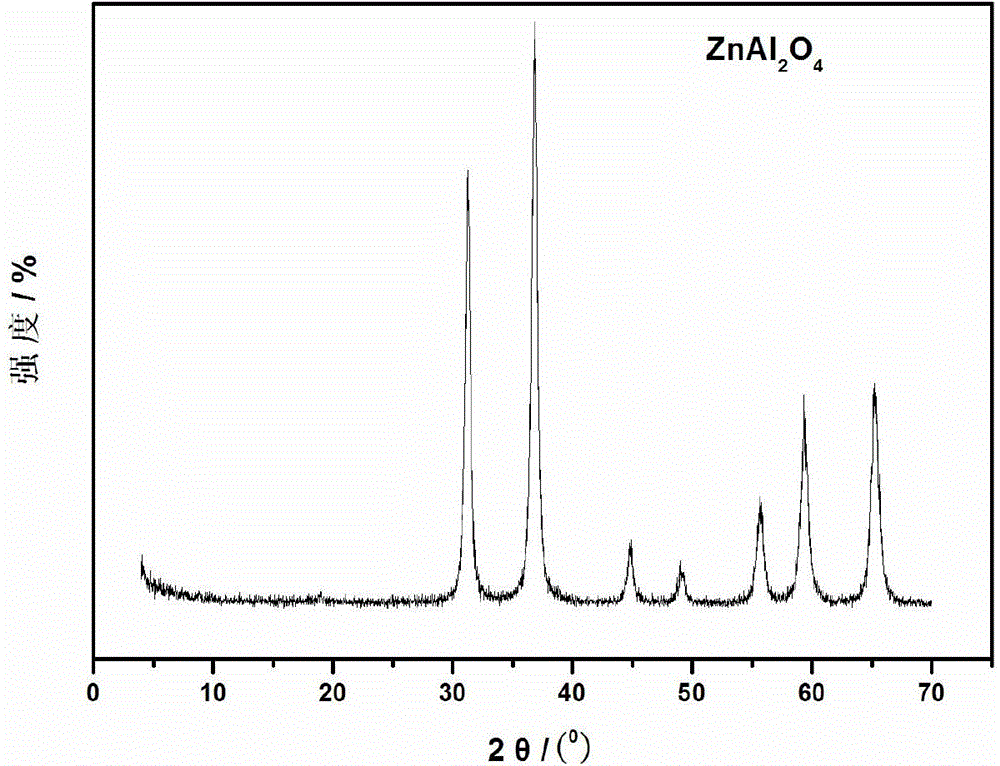

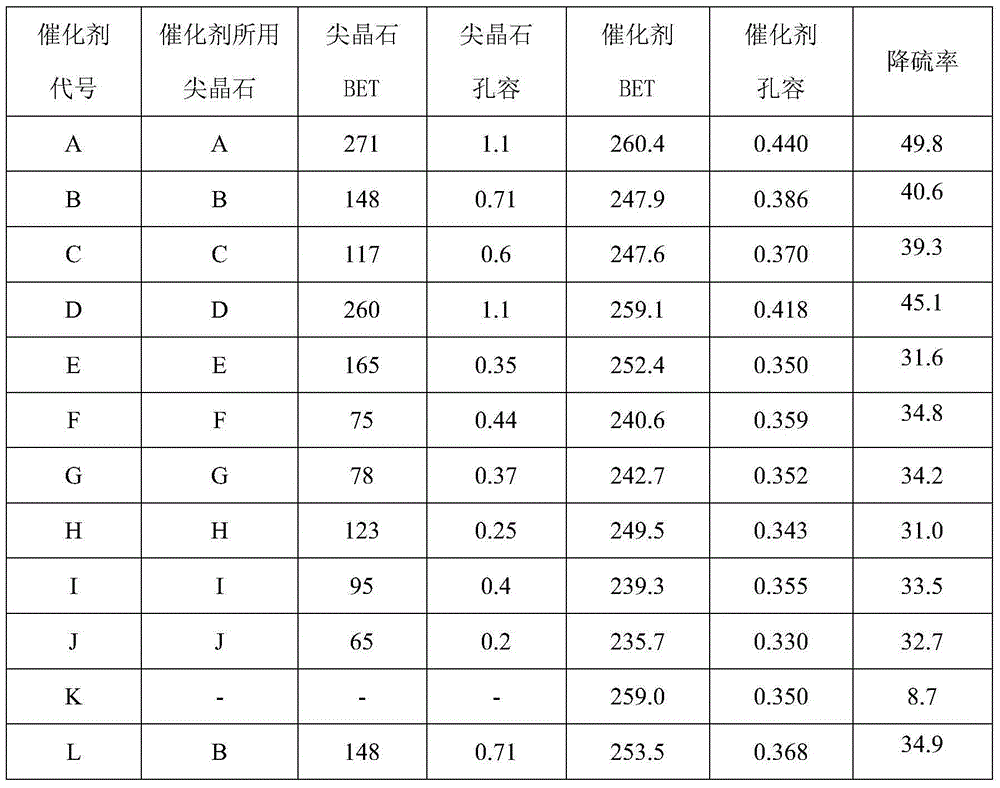

Embodiment 1

[0048] Dissolve 2009.4g of zinc nitrate in 1.8L of tap water, dissolve at 50°C, and stir for 10 minutes; add 1,075.2g of macroporous pseudothin, and stir for 10 minutes; add 100g of polystyrene and 50g of activated carbon as a pore-enlarging agent, stir, and heat at 85°C Aging for 30 minutes, drying at 80°C overnight, and low-temperature roasting at 650°C for 3 hours. A zinc-aluminum spinel sample A was obtained. Specific surface area 271m 2 / g, pore volume 1.1cc / g, particle size 26nm.

Embodiment 2

[0050] Dissolve 1694.2g of zinc nitrate in 1.3L of tap water, dissolve at 50°C, and stir for 10 minutes; add 906.2g of macroporous pseudothin, and stir for 10 minutes; add 60g of starch as a pore-enlarging agent, stir, and age at 80°C for 60 minutes, 80 ℃ dried overnight, and low-temperature roasting at 650 ℃ for 3 hours. Gained zinc-aluminum spinel sample B. Specific surface area 148m 2 / g, pore volume 0.71cc / g, particle size 27nm.

Embodiment 3

[0052] Dissolve 1489.3g of zinc sulfate in 2.8L of tap water, dissolve at 50°C, and stir for 10 minutes; add 752.6g of macroporous pseudothin, and stir for 10 minutes; add 100g of coconut shell carbide as a pore-enlarging agent, stir, and age at 80°C for 60 Minutes, dried overnight at 80°C, and calcined at 750°C for 1 hour. Gained zinc-aluminum spinel sample C. Specific surface area 117m 2 / g, pore volume 0.6cc / g, particle size 33nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com