Catalytic cracking catalyst and preparation method and application thereof

A catalytic cracking and catalyst technology, applied in the field of processing paraffinic base oil or Fischer-Tropsch synthetic oil, catalyst additives or sub-catalysts, can solve the problems of increased catalyst consumption, reduced tower bottom oil yield, and affecting refinery benefits, etc., to achieve Good cracking activity and lower octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This example illustrates the preparation of an aluminum phosphate binder used in the catalyst of the present invention, which is prepared according to the method described in patent CN200910237012.5.

[0068] 4.39 kg of pseudo-boehmite (containing A1 2 o 3 3 kilograms) and 5.4 kilograms of decationized water beating for 30 minutes, under stirring, add 10.3 kilograms of 85% concentrated phosphoric acid in the slurry, then add 5.28 kilograms of 68% concentrated nitric acid, continue to stir and react for 45 minutes, and the colorless and transparent phosphoraluminum sol is obtained. Its pH is 1.3. After analysis, the aluminum phosphate contains 11.1% by weight of P, 6.5% by weight of Al, and P / Al (weight)=1.77.

Embodiment 2

[0070] This example illustrates the preparation of a Beta zeolite for use in the catalyst according to the invention.

[0071]Get 0.6g of aluminum sulfate (containing 18 g water of crystallization) and 0.318g of sodium hydroxide dissolved in 7.36ml of deionized water, stir for 30 minutes, then add 0.72g of white carbon black, continue to stir for 10 minutes to form a silica-alumina gel, 0.036 g Beta zeolite seeds were added. Continue to stir the gel obtained above for 10 minutes, put it into a stainless steel reaction kettle with polytetrafluoroethylene lining, and conduct hydrothermal crystallization at 120° C. for 72 hours. After cooling, filter at room temperature and dry at 120°C. Get the product, its n(SiO 2 ) / n(A1 2 o 3 ) = 10.2.

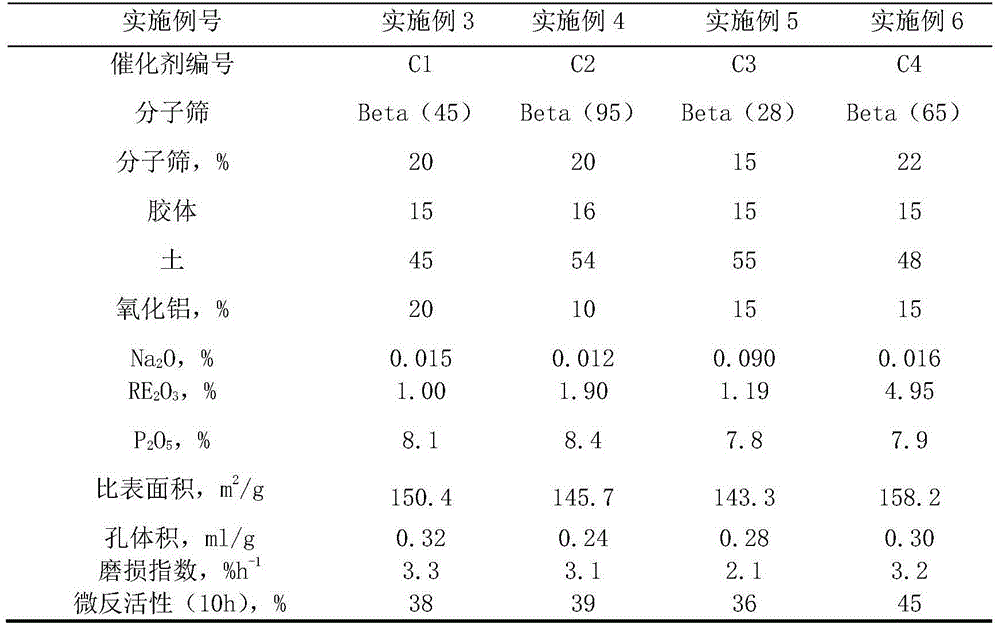

Embodiment 3

[0073] This example illustrates the preparation of a catalyst according to the method of the invention.

[0074] (1) Add 300 g of the sample obtained in Example 2 to pulp with 2.8 L of deionized water, add 150 g of ammonium sulfate and 150 g of oxalic acid, adjust the pH to 2.5, react at 80° C. for 1 hour, filter, wash, and dry at 120° C. Repeat this 3 times. Before the third filtration, add La(NO 3 ) 3 Solution (La 2 o 3 (103.13g / L) 160.9ml, stirred for 30min, filtered off the liquid, dried the solid sample at 120°C for 4h, and calcined at 550°C for 2h to obtain the desired modified Beta zeolite. The relative crystallinity of the sample measured by XRD is 58%, and the Na 2 O is 0.05%, RE 2 o 3 5.4%, SiO 2 / A1 2 o 3 for 45.

[0075] (2) While stirring, mix 1780g of kaolin and 2855ml of decationized water for 30min, add La(NO 3 ) 3 Solution (La 2 o 3 103.13g / L) 264ml, stirred for 1h, 1.18kg of aluminum phosphate prepared according to the method in Example 1 was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com