Method for preparing dispersive submicron honeycomb-shaped spherical platinum powder

A sub-micron, honeycomb-like technology, applied in the field of chemical liquid-phase reduction of platinum precursors for sub-micron honeycomb spherical platinum powder, can solve the problem of the particle size distribution range of the amorphous structure of platinum powder particles, and the tendency of ultra-fine platinum powder to harden. Agglomeration and other problems, to achieve the effect of narrow particle size distribution, low cost and convenient screen printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of dispersant solution: configuration 300ml dissolved 1.56g Aqueous solution of gum arabic as dispersant;

[0029] (2) Preparation of dispersed submicron-sized honeycomb spherical platinum powder: under stirring, Magrus salt (the concentration of platinum is 60g / L ) into the dispersant solution in step (1), then add concentrated ammonia water drop by drop and heat up, with vigorous stirring to dissolve the Magrus salt, stop adding concentrated ammonia water, and then add it all at once 14g Ascorbic acid, continue to stir the reaction after adding 30~50min , and finally adjust the reaction solution pH value to strong acidity, continue to heat up to 90 ℃, and stirred for a period of time, the product produced by the reaction was filtered, washed twice with water and acetone, and finally vacuum-dried to obtain dispersed submicron honeycomb spherical platinum powder;

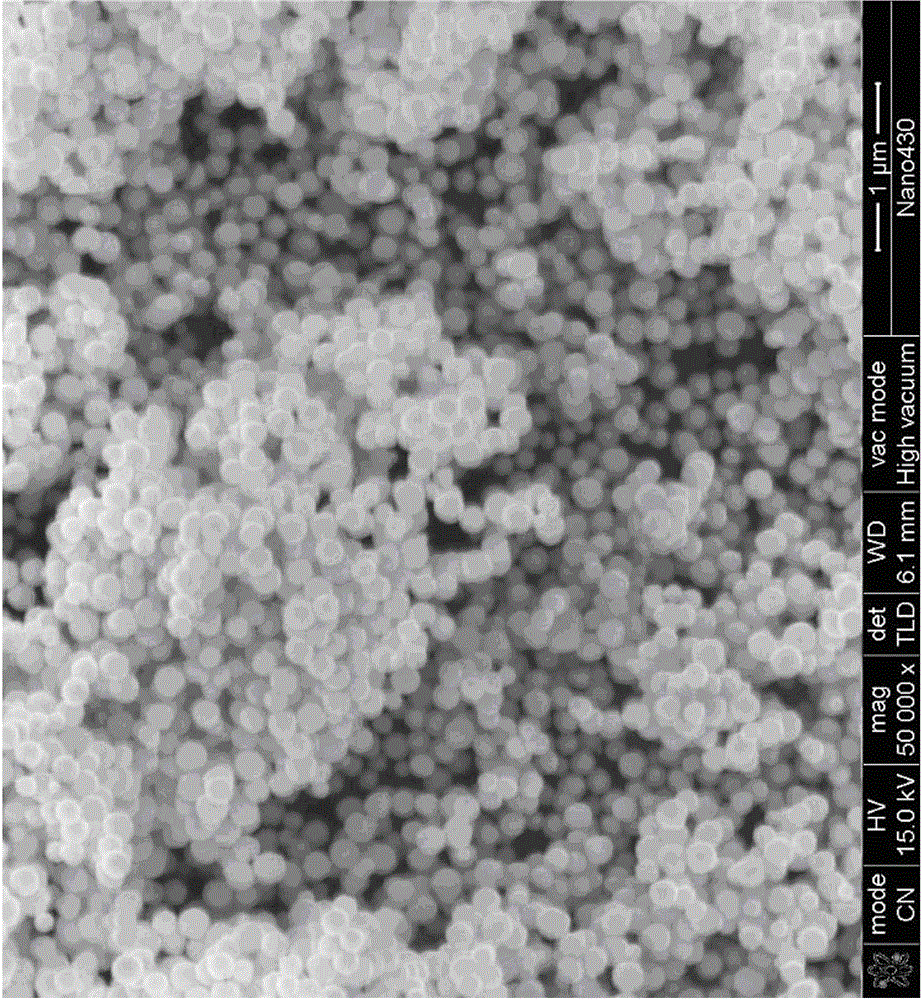

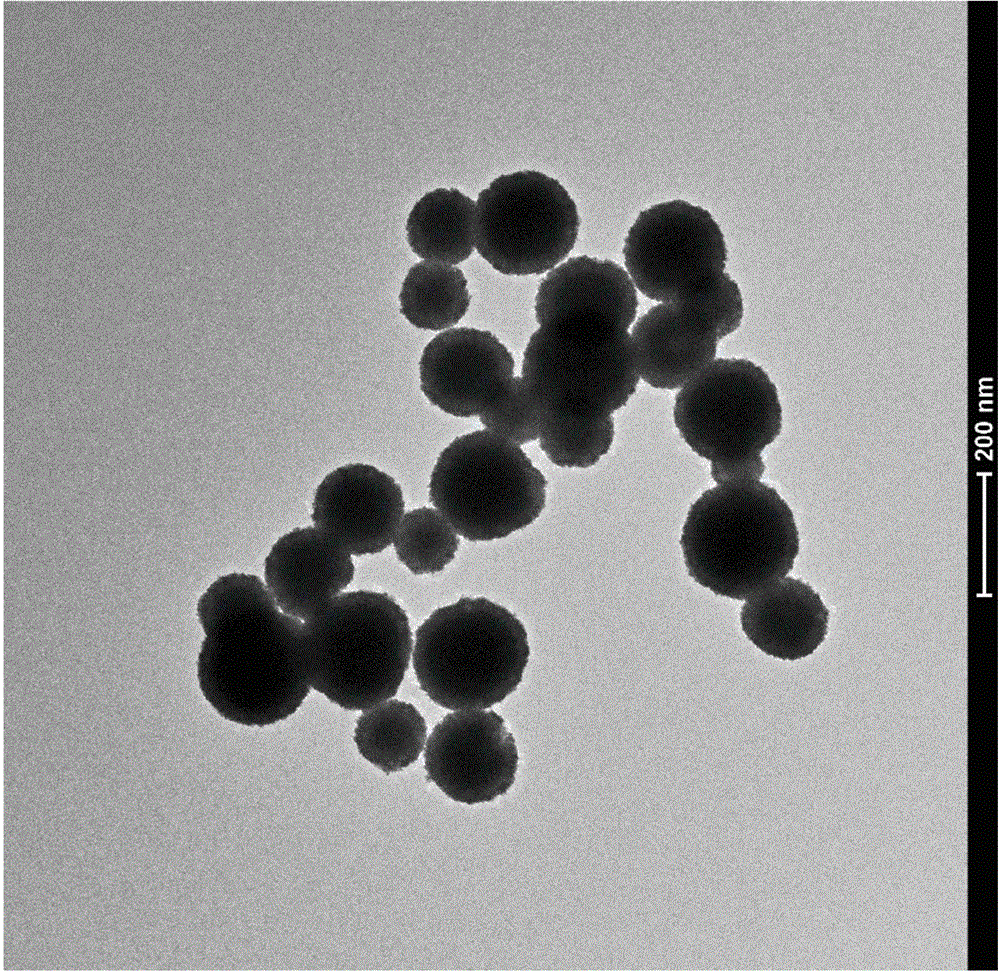

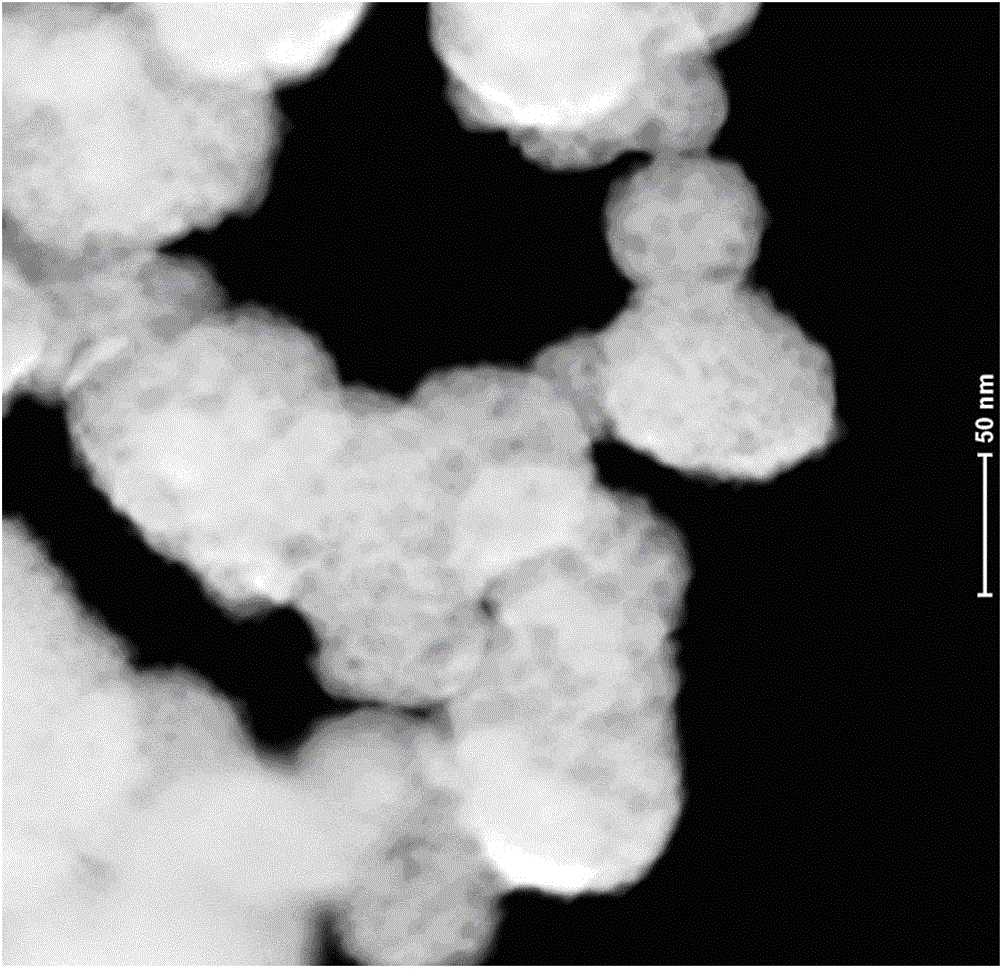

[0030] The submicron honeycomb-shaped platinum powder particles prepared in this e...

Embodiment 2

[0032] (1) Preparation of dispersant solution: configuration 300ml dissolved 0.78g Aqueous solution of gum arabic as dispersant;

[0033] (2) Preparation of dispersed submicron honeycomb spherical platinum powder: under stirring, add Magreus salt to the step (the concentration of platinum is 60g / L ) into the dispersant solution in (1), then add concentrated ammonia water drop by drop and heat up, with vigorous stirring to dissolve the Magrus salt, and stop adding concentrated ammonia water. Add it all at once 14g Ascorbic acid, continue to stir the reaction after adding 30~50min , and finally adjust the reaction solution pH value to strong acidity, continue to heat up, and stir for a period of time, filter the product produced by the reaction, wash it twice with water and acetone, and finally dry it in vacuum to obtain dispersed submicron spherical platinum powder;

[0034] The submicron honeycomb-shaped platinum particles prepared in this embodiment are uniform spheri...

Embodiment 3

[0036] (1) Preparation of dispersant solution: configuration 200ml dissolved 1.5g Aqueous solution of Pluronic F127 as dispersant;

[0037](2) Preparation of dispersed submicron honeycomb spherical platinum powder: Potassium chloroplatinite (platinum salt concentration of 50g / l ) into the dispersant solution in step (1), and then quickly complete the addition 200ml Concentration is 88% of formic acid, continue to stir the reaction after adding 30~50min , and finally adjust the reaction solution pH value to strong acidity, continue to heat up, and stir for a period of time, filter the product produced by the reaction, wash it twice with water and acetone, and finally dry it in vacuum to obtain dispersed submicron spherical platinum powder;

[0038] The submicron honeycomb-shaped platinum particles prepared in this example are ellipsoidal or nearly spherical, with an average particle diameter of 70nm , no agglomeration, good dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com