Flexible heat insulation material and preparation method thereof

A technology of flexible heat insulation material and heat insulation layer, which can be applied in heat exchange equipment, pipeline protection through heat insulation, mechanical equipment, etc., can solve the problems of poor heat insulation performance and inability to meet high-efficiency heat insulation, and achieve heat insulation performance Good, excellent chemical stability, excellent radiation shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] On the one hand, an embodiment of the present invention provides a method for preparing a flexible heat insulating material, and the method for preparing the flexible heat insulating material mainly includes the following steps:

[0043] 1) Mix 0-20 parts by weight of pulp, 80-100 parts by weight of alumina fiber and 600-2000 parts by weight of water, and stir evenly to obtain raw material slurry.

[0044] Specifically, the main component of pulp in this step is wood fiber. The role of pulp is mainly to increase the strength of alumina fibers and improve the flexibility of alumina fibers, so that the final heat insulation material has the flexibility of paper.

[0045] In this step, the alumina fiber is preferably chopped fiber, the alumina content in the alumina fiber is greater than 90%, and the alumina fiber density is greater than 3.0g / cm 3, the diameter is 1-10 μm, and the length is preferably 1-5 mm. The alumina fiber in this step has low thermal conductivity, h...

Embodiment 1

[0073] 1) Take 6 parts by weight of paper pulp and add it into 60 parts by weight of deionized water, and then stir evenly in a pulper to obtain 66 parts by weight of paper pulp slurry.

[0074] 2) Add 94 parts by weight of alumina fibers and 66 parts by weight of paper pulp slurry prepared in step 1) into 1566 parts by weight of deionized water, and stir evenly to obtain raw material slurry.

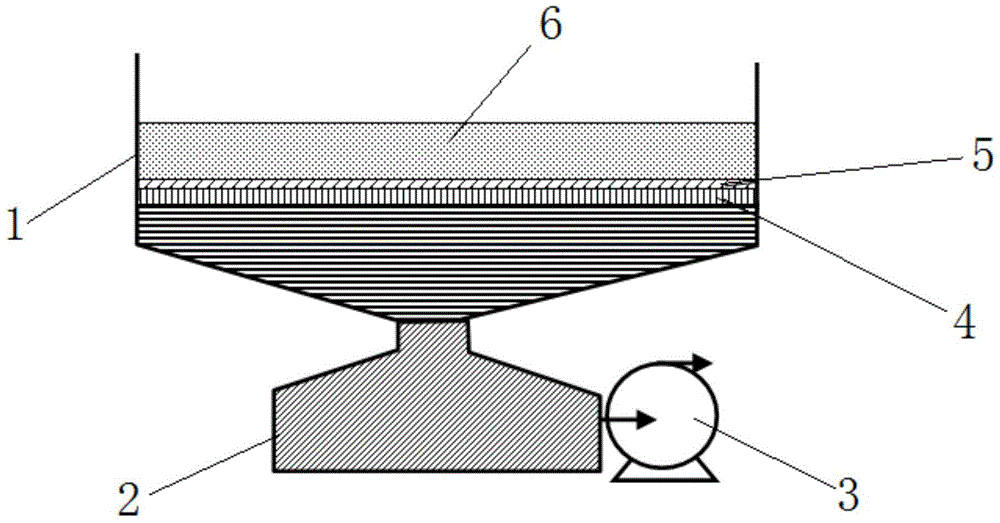

[0075] 3) Lay a layer of non-woven fabric on the bottom of the vacuum filtration device, add the raw material slurry into the vacuum filtration device, start the vacuum pump for suction filtration, part of the water in the raw material slurry will be discharged, and the alumina fibers will remain On the non-woven fabric, the solid phase content in the raw material slurry is controlled to be 70% to obtain an alumina fiber preform.

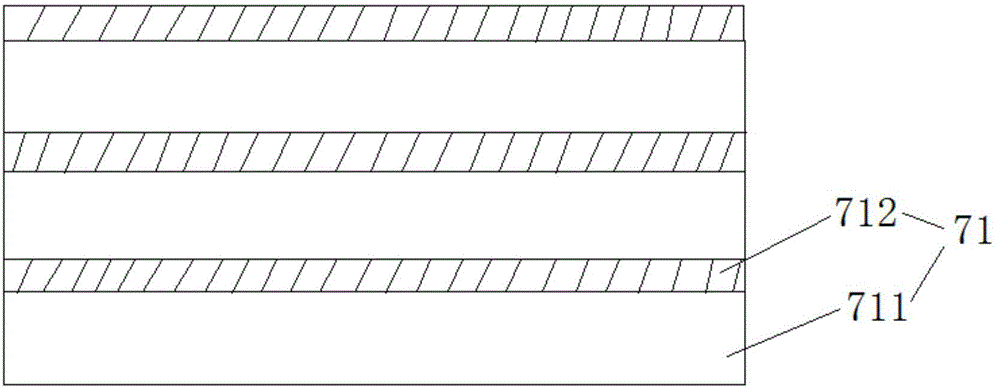

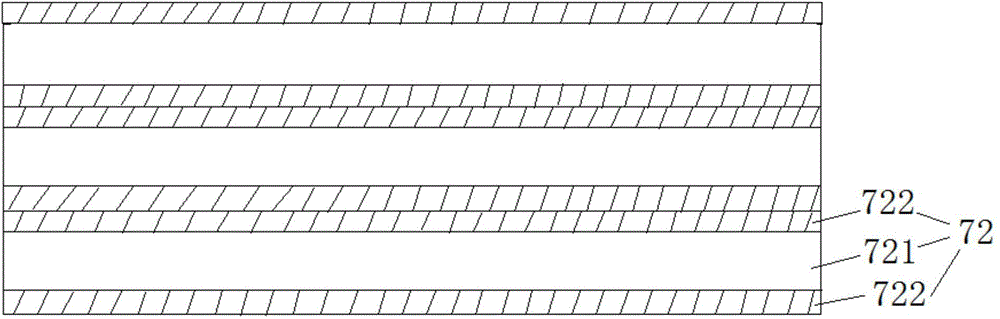

[0076] 4) Evenly brush white latex on the surface of the graphite foil and cover one side of the alumina fiber prefabricated body to obtain a heat insulating...

Embodiment 2

[0079] 1) Take 10 parts by weight of paper pulp and add it into 100 parts by weight of deionized water, and then stir evenly in a pulper to obtain 110 parts by weight of paper pulp slurry.

[0080] 2) Add 90 parts by weight of alumina fibers and 110 parts by weight of paper pulp slurry prepared in step 1) into 1500 parts by weight of deionized water, and stir evenly to obtain raw material slurry.

[0081] 3) Lay a layer of Dacron cloth on the bottom of the vacuum filtration device, add the raw material slurry obtained in step 2) into the vacuum filtration device, start the vacuum pump for suction filtration, and part of the moisture in the raw material slurry is discharged, and the alumina The fibers are left on the non-woven fabric, and the solid phase content in the slurry is controlled to be 70% to obtain an alumina fiber preform.

[0082] 4) Evenly brush white latex on the surface of the graphite foil and cover it on one side of the alumina fiber prefabricated body to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com