Thermoplastic polyolefin waterproof coiled material and preparation method

A thermoplastic polyolefin and waterproof membrane technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of being easily corroded by corrosive oxidants, aromatic hydrocarbons, etc., and the puncture resistance is not high. Corrosion resistance is not good and other problems, to achieve the effect of reducing material cost, high seam peeling strength, high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

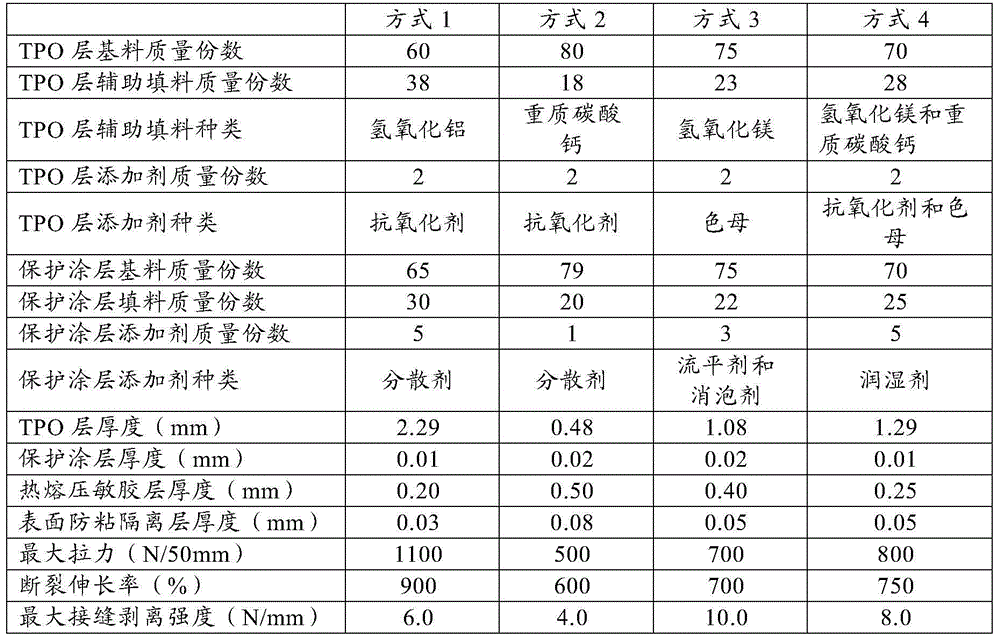

[0039] combined with figure 1 and specific embodiments can better understand the present invention, the provided appended figure 1 The data and materials used in the following specific implementation are only a preferred implementation mode of the present invention, and do not constitute a special limitation to the present invention. Those skilled in the art can change the thickness of each layer, the additives used, etc. on the basis of understanding the technical solutions of the present invention, which still belong to the protection scope of the present invention.

[0040] Please refer to figure 1 , The TPO waterproof membrane of this embodiment is used for pre-paving anti-adhesive construction, including a surface anti-adhesive isolation layer 1, a protective coating 2, a hot-melt pressure-sensitive adhesive layer 3, and a TPO sheet layer 4 arranged in sequence. The TPO sheet layer 4 is made of base material, auxiliary filler and additives, the base material of the TPO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com