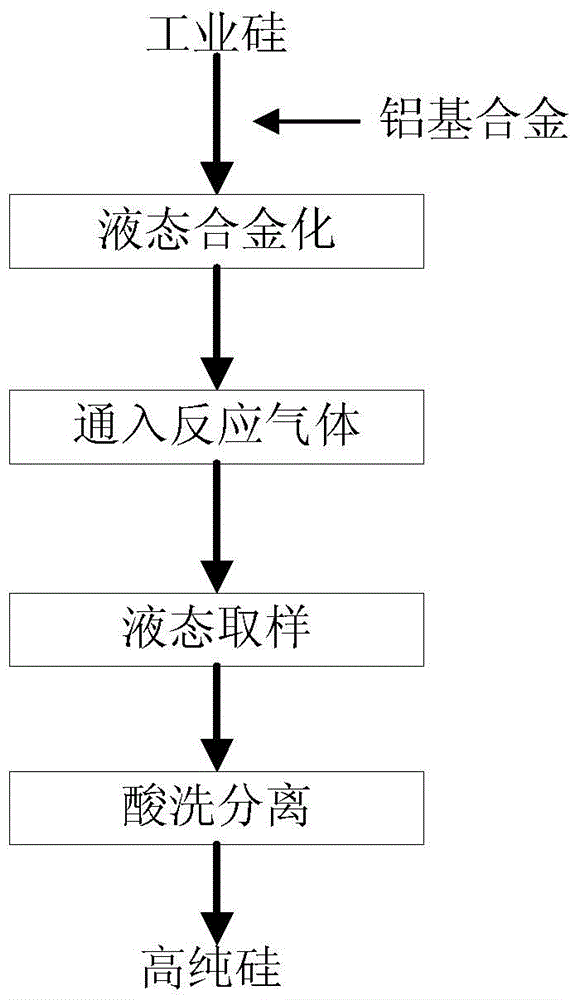

Method for quickly removing boron from silicon by introducing gas to Al-Si alloy

An alloy and fast technology, applied in chemical instruments and methods, silicon compounds, non-metallic elements, etc., can solve the problem of high energy consumption in the refining process, achieve the effects of shortening solidification time, rapid solidification, and improved processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix 90g of silicon with 210g of metal aluminum (purity 99.99%), place in an alumina crucible (graphite crucible with outer shell), and place in an intermediate frequency induction furnace. Adjust the heating power to 0.8kW and maintain the temperature at 1223K to completely melt the alloy. Pour Ar-H into the alloy melt 2 Mixed gas, where Ar and H 2 The gas flow rate is 1:1, the gas flow rate is 5×10 -9 m 3 / s, ventilation time is 9000s, then take out the crucible from the furnace, quickly cool and solidify to obtain the alloy sample, treat the alloy sample with hydrochloric acid, dissolve the metal aluminum in the alloy sample, obtain refined silicon, analyze the refined silicon with ICP-OES The content of boron. See Table 1 for comparison of purification results.

[0020] Table 1

[0021] Impurity element

Embodiment 2

[0023] Mix 90g of silicon with 210g of metal aluminum (purity 99.99%), place in an alumina crucible (graphite crucible with outer casing), and place in an intermediate frequency induction furnace. Adjust the heating power to 1.2kW and maintain the temperature at about 1473K to completely melt the alloy. Then pass H into the alloy melt 2 , Where H 2 The gas flow rate is 3.3×10 -9 m 3 / s, aeration time of 12600s, then take out the crucible from the furnace, quickly cool and solidify to obtain an alloy sample, treat the alloy sample with hydrochloric acid, dissolve the metal aluminum in the alloy sample, obtain refined silicon, analyze the refined silicon with ICP-OES The content of boron. See Table 2 for comparison of purification results.

[0024] Table 2

[0025] Impurity element

Embodiment 3

[0027] Mix 90g of silicon with 210g of metallic aluminum (purity 99.99%), place it in an alumina crucible (graphite crucible with jacket), and place it in an intermediate frequency induction furnace. Adjust the heating power to 2.0kW and maintain the temperature at about 1673K to completely melt the alloy. Then pass H into the alloy melt 2 , Where H 2 The gas flow rate is 1.7×10 -9 m 3 / s, ventilation time is 1800s, then the crucible is taken out of the furnace, and the alloy sample is obtained by rapid cooling and solidification. The alloy sample is treated with hydrochloric acid to dissolve the metal aluminum in the alloy sample to obtain refined silicon, and analyze the refined silicon by ICP-OES The content of boron. See Table 3 for comparison of purification results.

[0028] table 3

[0029] Impurity element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com