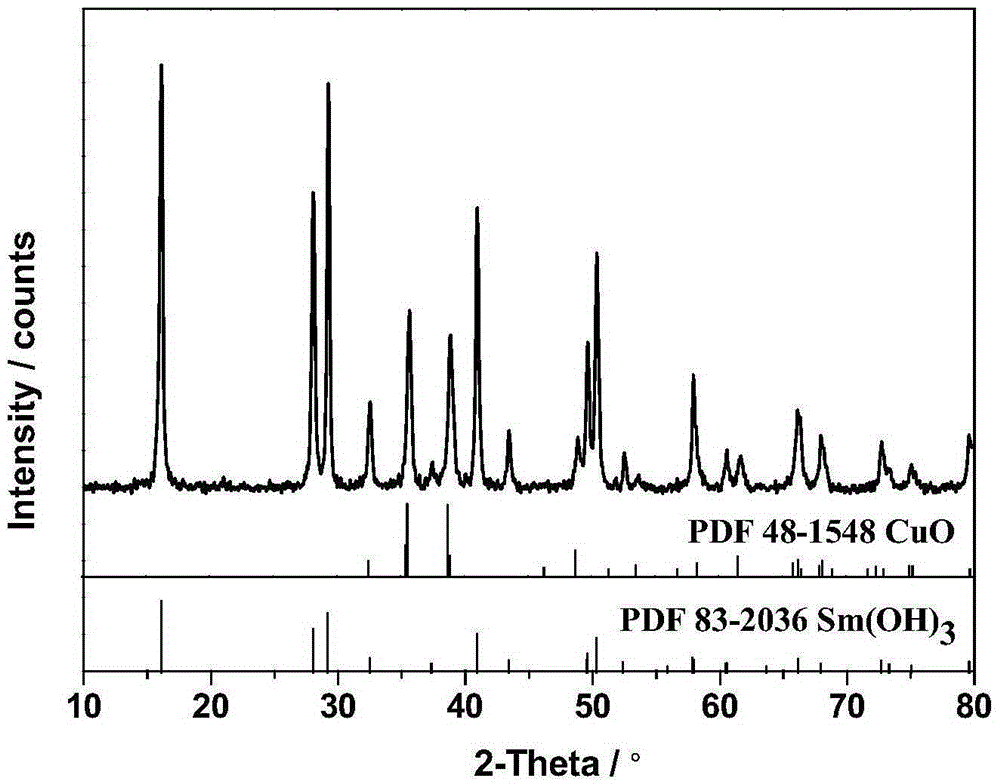

A method for preparing sm(oh)3/cuo nanocomposites by microwave hydrothermal method

A technology of nanocomposite and microwave hydrothermal method, which is applied in the field of nano-semiconductor composite material preparation, can solve the problems of low visible light and solar energy utilization rate of only 1%, and achieve narrow particle size distribution, controllable crystal morphology and speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) The analytically pure Sm(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10 ml deionized water at a molar ratio of 1:0.2 to prepare Sm 3+ Solution A with a concentration of 0.1mol / L;

[0021] 2) Under magnetic stirring, use analytically pure sodium hydroxide to adjust the pH of solution A to 7, and continue stirring for 1 hour to form a reaction precursor;

[0022] 3) Pour the reaction precursor solution into a microwave hydrothermal reaction kettle with deionized water as a solvent, seal the kettle and put it into a microwave hydrothermal reaction instrument, perform a hydrothermal reaction at 100°C for 2 hours, and naturally cool to room temperature after the reaction;

[0023] 4) The product was washed by centrifugation with deionized water and absolute ethanol for 4 to 6 times in sequence, and dried in an electric vacuum oven at 60°C for 0.5h to obtain Sm(OH) 3 / CuO nanocomposites.

Embodiment 2

[0025] 1) The analytically pure Sm(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10 ml deionized water at a molar ratio of 1:0.5 to prepare Sm 3+ Solution A with a concentration of 2mol / L;

[0026] 2) Under magnetic stirring, use analytically pure sodium hydroxide to adjust the pH of solution A to 9, and continue stirring for 1 hour to form a reaction precursor;

[0027] 3) Pour the reaction precursor solution into a microwave hydrothermal reaction kettle with deionized water as a solvent, seal the kettle and put it into a microwave hydrothermal reaction instrument, perform a hydrothermal reaction at 100°C for 2 hours, and naturally cool to room temperature after the reaction;

[0028] 4) The product was successively washed with deionized water and absolute ethanol for 4 to 6 times, and dried in an electric vacuum oven at 70°C for 1 hour to obtain Sm(OH) 3 / CuO nanocomposites.

Embodiment 3

[0030] 1) The analytically pure Sm(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10 ml deionized water at a molar ratio of 1:0.8 to prepare Sm 3+ Solution A with a concentration of 0.5mol / L;

[0031] 2) Under magnetic stirring, use analytically pure sodium hydroxide to adjust the pH of solution A to 11, and continue stirring for 1.5 h to form a reaction precursor;

[0032] 3) Pour the reaction precursor solution into a microwave hydrothermal reaction kettle with deionized water as a solvent, seal the kettle and put it into a microwave hydrothermal reaction instrument, perform a hydrothermal reaction at 130°C for 1.5 hours, and naturally cool to room temperature after the reaction;

[0033] 4) The product was successively washed with deionized water and absolute ethanol for 4 to 6 times, and dried in an electric vacuum oven at 80°C for 1 hour to obtain Sm(OH) 3 / CuO nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com