Method for removing COD of membrane concentrated liquid

A concentrated water and hydrogen peroxide technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of increased site occupation and high treatment costs, and achieve weight reduction, difficulty and cost reduction, and water treatment costs cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

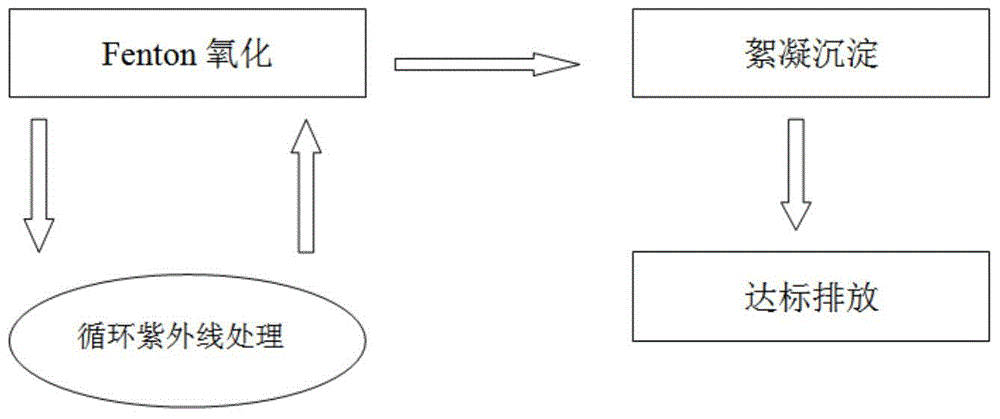

Method used

Image

Examples

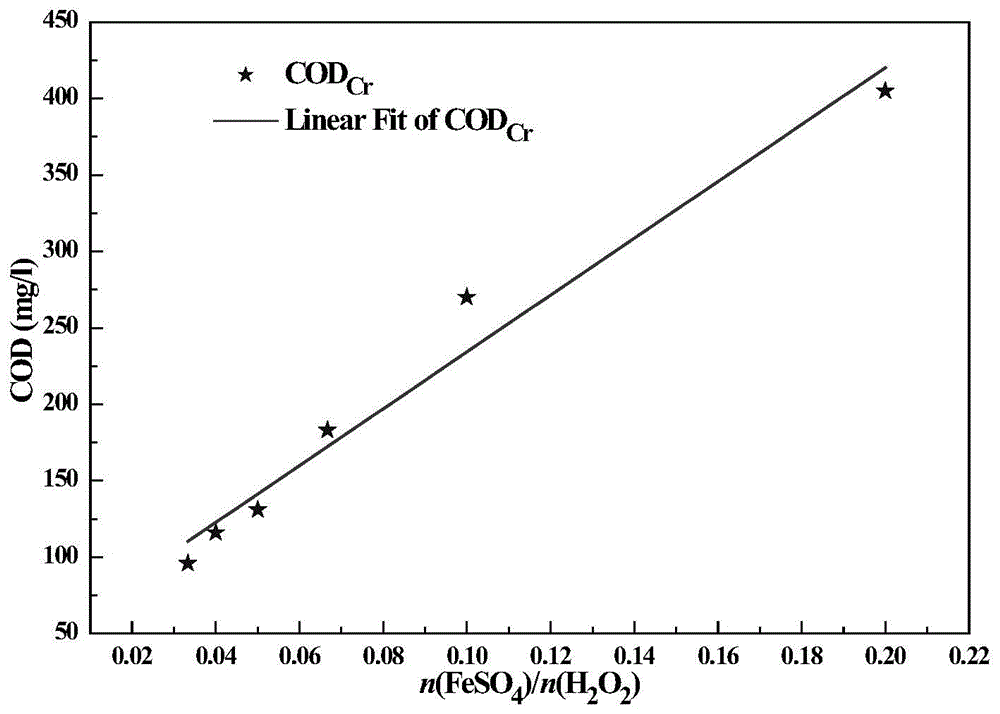

Embodiment 1

[0046] In the present embodiment, the effective volume of the oxidation pond is 5m 3 , The effective volume of the ultraviolet treatment device is 50L, and a 100W ultraviolet lamp and corresponding driver are used. COD is measured by the method for measuring the chemical oxygen demand in GB11914-89 of the film concentrated water after the reuse of reclaimed water in the treatment of electroplating wastewater Cr The value is 589mg / L, and the concentration of heavy metals meets the requirements of "National Standard Sewage Comprehensive Discharge Standard of the People's Republic of China (GB8978-1996)".

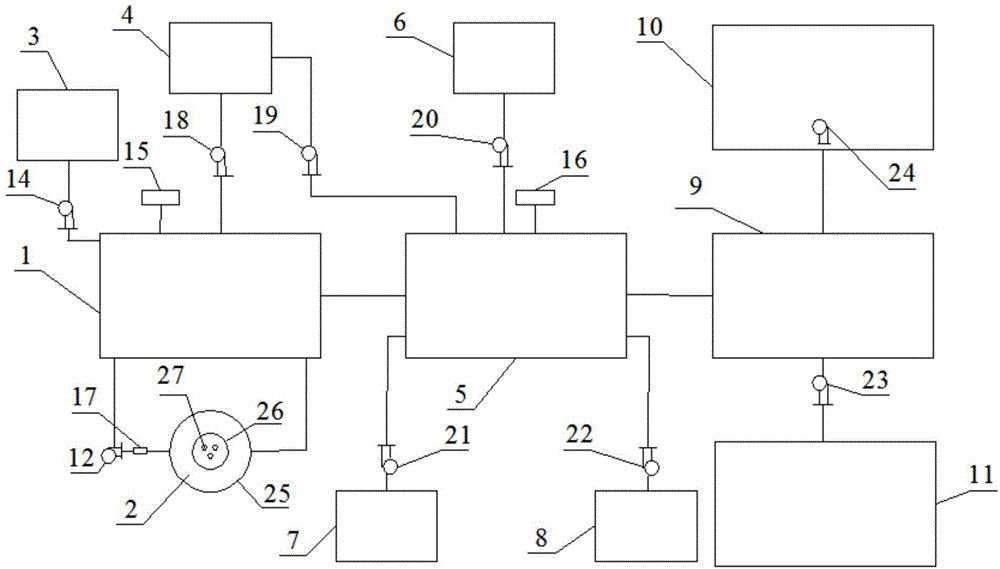

[0047] (1) Cyclic oxidation treatment under ultraviolet irradiation: Inject 5000L membrane concentrated water into the oxidation pool, and in the oxidation pool: put 3kg of FeSO4·7H 2 O and 4.18 kg of H 2 C 2 o 4 2H 2 O, wait for 10min; adjust the pH value of the solution to 3-4, pH=3.1 in this embodiment; open H 2 o 2 Dosing pump, add 22.5L of 30%H 2 o 2 ; Turn on th...

Embodiment 2

[0051] In this embodiment, the effective volume of the oxidation tank is 10m 3 , The effective volume of the ultraviolet irradiation device is 100L, and two 100W ultraviolet lamps and corresponding drivers are used. COD is measured by the method for measuring the chemical oxygen demand in GB11914-89 of the film concentrated water after the reuse of reclaimed water in the treatment of electroplating wastewater Cr The value is 782mg / L, the content of heavy metal zinc ions is 21mg / L, and the content of nickel ions is 13mg / L.

[0052] (1) Cyclic oxidation treatment under ultraviolet irradiation: Inject 10,000L membrane concentrated water into the oxidation pool, and in the oxidation pool: put 6.79kg of FeSO4·7H 2 O and 9.24 kg of H 2 C 2 o 4 2H 2 O, wait for 10min; adjust the pH value of the solution to 3-4, pH=3.0 in this embodiment; open H 2 o 2Dosing pump, add 59.9L of 30%H 2 o 2 ; Turn on the circulating pump and the ultraviolet lamp, and make the water in the oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com