An Atmospheric Pressure Surface Discharge Plasma Device for Surface Modification of Glass and Polymer Materials

A polymer material and surface modification technology, applied in the field of material surface treatment, can solve the problems of low plasma efficiency, difficult to obtain plasma, and low breakdown voltage on the surface of the discharge medium, and achieve improved hydrophilicity and high industrial efficiency. The effect of promoting value and improving the surface energy of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

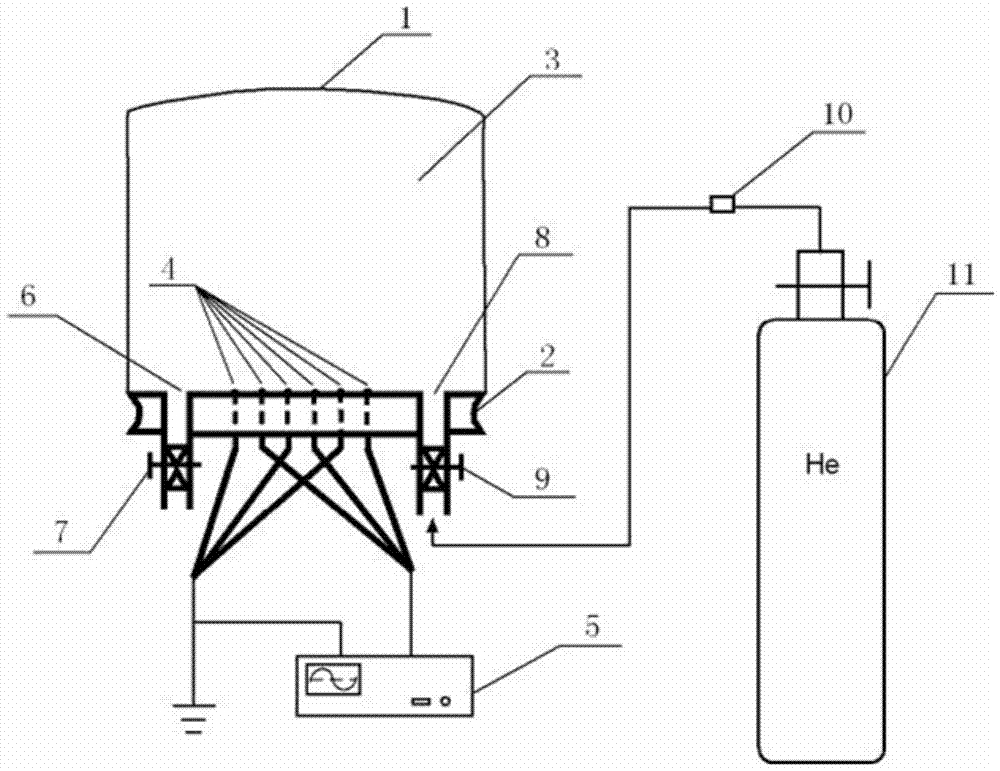

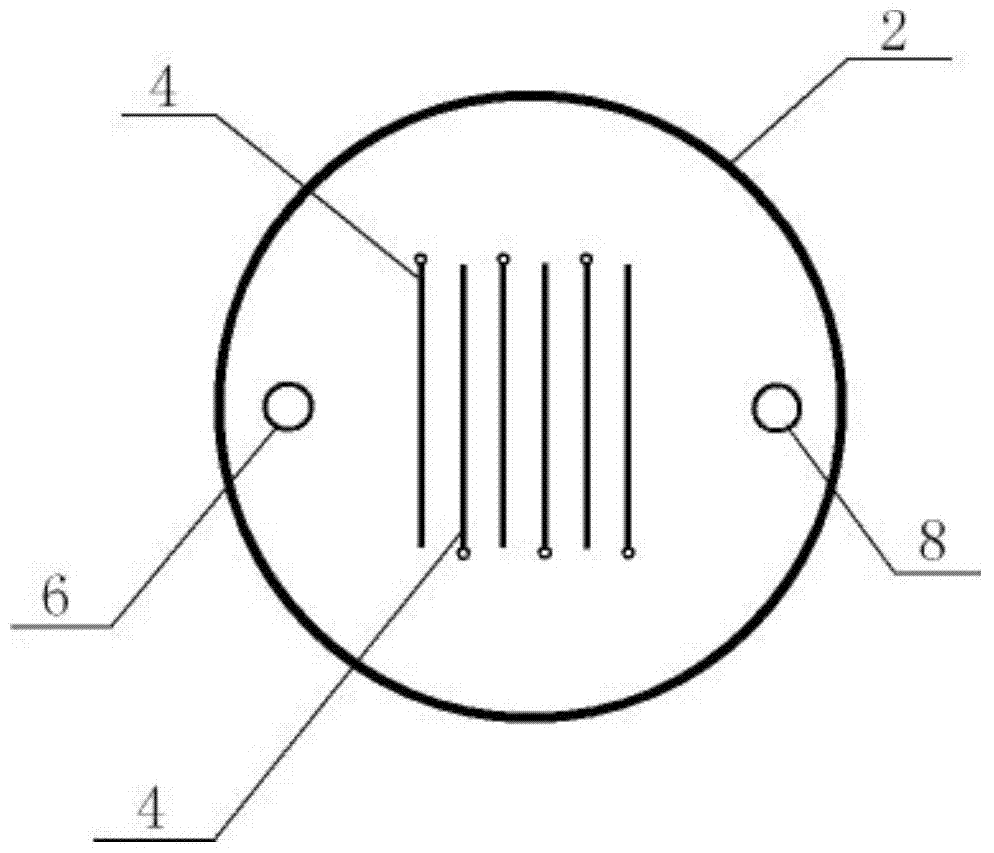

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0016] First, the material to be processed is directly placed on the plasma discharge area on the wire electrode 4, and a plastic electrical insulating film 1 with good air tightness and flexibility is covered on the edge of the electrical insulating dielectric plate 2 to be fixed and sealed to prevent air leakage. In this way, the reaction chamber 3 is formed; open the air extraction valve 7 to exhaust the air in the reaction chamber 3, either to flatten the plastic electrical insulating film 1 or use a manual air pump to assist in extracting all the gas, close the air extraction valve 7; open the flow meter 10 And the inlet valve 9, the gas supply source 11 slowly inflates the reaction chamber 3 through the flow meter 10 and the inlet valve 9 until the plastic electrical insulating film 1 is supported by the working carrier gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com