SrTiO3-based high-frequency layered magnetoelectric composite material and preparation method thereof

A magnetoelectric composite material, high-frequency technology, applied in the field of material science, can solve the problems of poor magnetoelectric properties, difficult sintering of two phases, uneven dispersion, etc., achieve excellent dielectric and magnetoelectric properties, and the preparation method is simple and easy to implement, The effect of suppressing the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

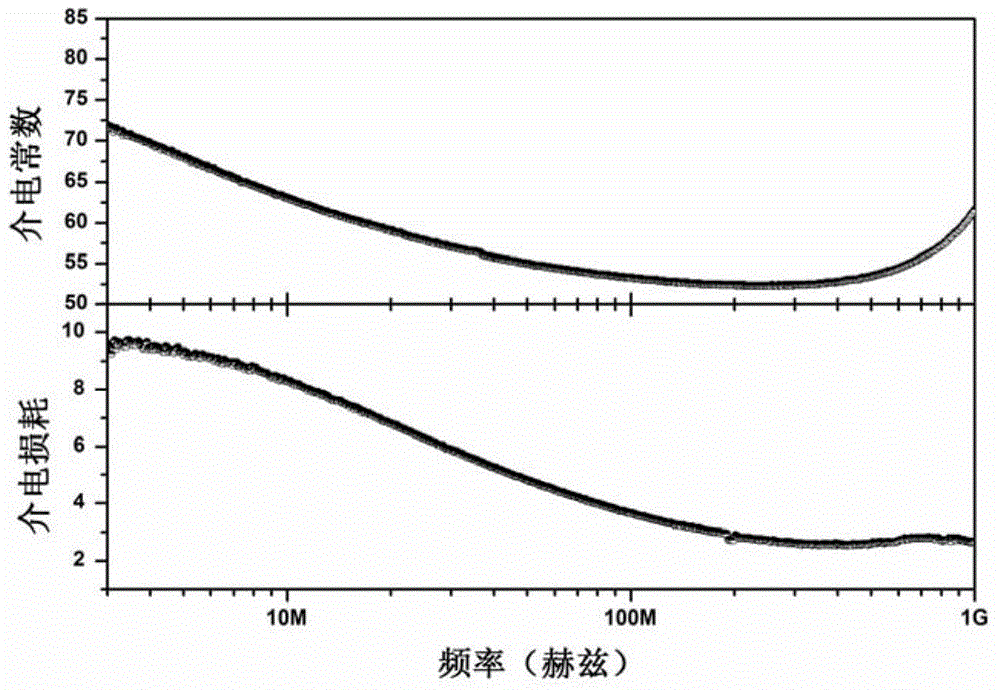

Embodiment 1

[0044] SrTiO 3 The chemical formula of the base high-frequency layered magnetoelectric composite material is: (1-x)SrTiO 3 / xNi 0.8 Zn 0.2 Fe 2 o 4 , where x is Ni 0.8 Zn 0.2 Fe 2 o 4 The mass percentage of , and x = 0.1.

[0045] The above SrTiO 3 A method for preparing a high-frequency layered magnetoelectric composite material, comprising the following steps:

[0046] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 、TiO 2 After preparation, it was mixed evenly by wet ball milling for 4 hours, then dried, sieved, briquetting, and then pre-fired at 1200°C for 6 hours to obtain a block product, and then the block product was crushed and passed through a 120-mesh sieve to obtain SrTiO 3 Powder;

[0047] (2) According to the chemical formula Ni 0.8 Zn 0.2 Fe 2 o 4 Will analyze pure NiO, ZnO, Fe 2 o 3 After preparation, it was mixed evenly by wet ball milling for 6 hours, then dried, sieved, briquetting, and then pre-fired at 1150°C for ...

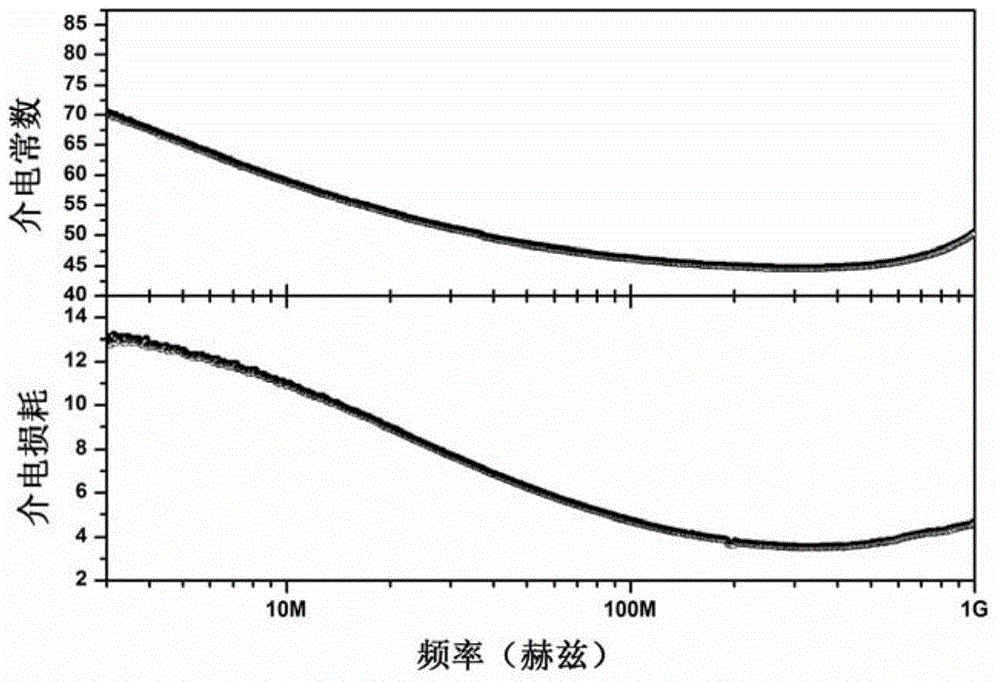

Embodiment 2

[0055] SrTiO 3 The chemical formula of the base high-frequency layered magnetoelectric composite material is: (1-x)SrTiO 3 / xNi 0.8 Zn 0.2 Fe 2 o 4 , where x is Ni 0.8 Zn 0.2 Fe 2 o 4 The mass percentage of , and x = 0.2.

[0056] The above SrTiO 3 A method for preparing a high-frequency layered magnetoelectric composite material, comprising the following steps:

[0057] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 、TiO 2 After preparation, it was mixed evenly by wet ball milling for 5 hours, then dried, sieved, briquetting, and then pre-fired at 1200°C for 4 hours to obtain a block product, and then the block product was crushed and passed through a 120-mesh sieve to obtain SrTiO 3 Powder;

[0058] (2) According to the chemical formula Ni 0.8 Zn 0.2 Fe 2 o 4 Will analyze pure NiO, ZnO, Fe 2 o 3 After preparation, it was mixed evenly by wet ball milling for 5 hours, then dried, sieved, briquetting, and then pre-calcined at 1150°C f...

Embodiment 3

[0066] SrTiO 3 The chemical formula of the base high-frequency layered magnetoelectric composite material is: (1-x)SrTiO 3 / xNi 0.8 Zn 0.2 Fe 2 o 4 , where x is Ni 0.8 Zn 0.2 Fe 2 o 4 The mass percentage of x=0.3.

[0067] The above SrTiO 3 A method for preparing a high-frequency layered magnetoelectric composite material, comprising the following steps:

[0068] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 、TiO 2 After the preparation, it was mixed evenly by wet ball milling for 4 hours, then dried, sieved, briquetting, and then pre-fired at 1200°C for 4 hours to obtain a block product, and then the block product was crushed and passed through a 120-mesh sieve to obtain the formula SrTiO 3 Powder;

[0069] (2) According to the chemical formula Ni 0.8 Zn 0.2 Fe 2 o 4 Will analyze pure NiO, ZnO, Fe 2 o 3 After preparation, it was mixed evenly by wet ball milling for 4 hours, then dried, sieved, briquetting, and then pre-fired at 115...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| magnetic loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com