A preparing method of 2-methyl-2-butene

A technology of butene and methyl, which is applied in the field of isomerization of fixed bed reactor to prepare 2-methyl-2-butene, which can solve the problems of short catalyst life and achieve long life, good anti-coking performance and high reaction yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

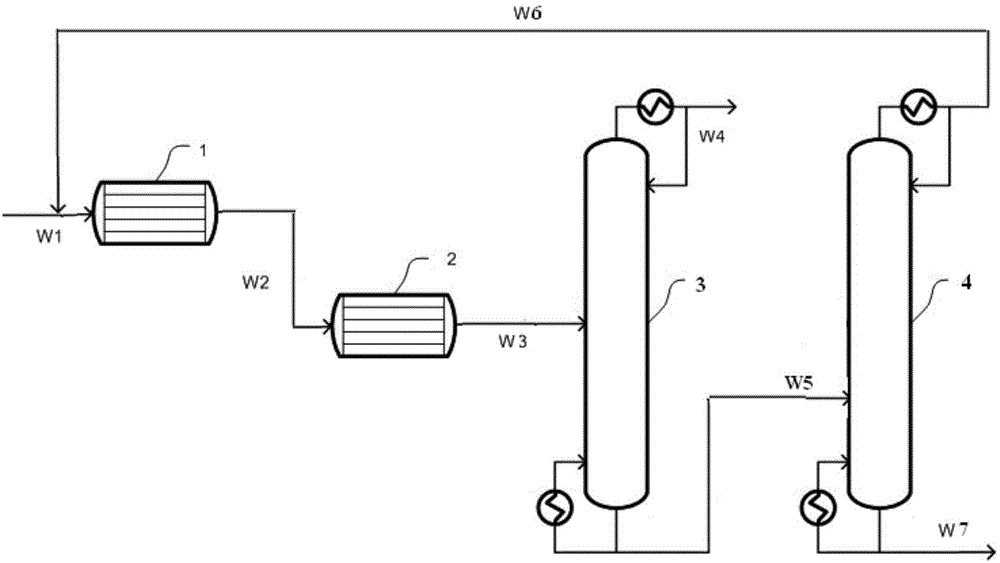

Method used

Image

Examples

Embodiment 11

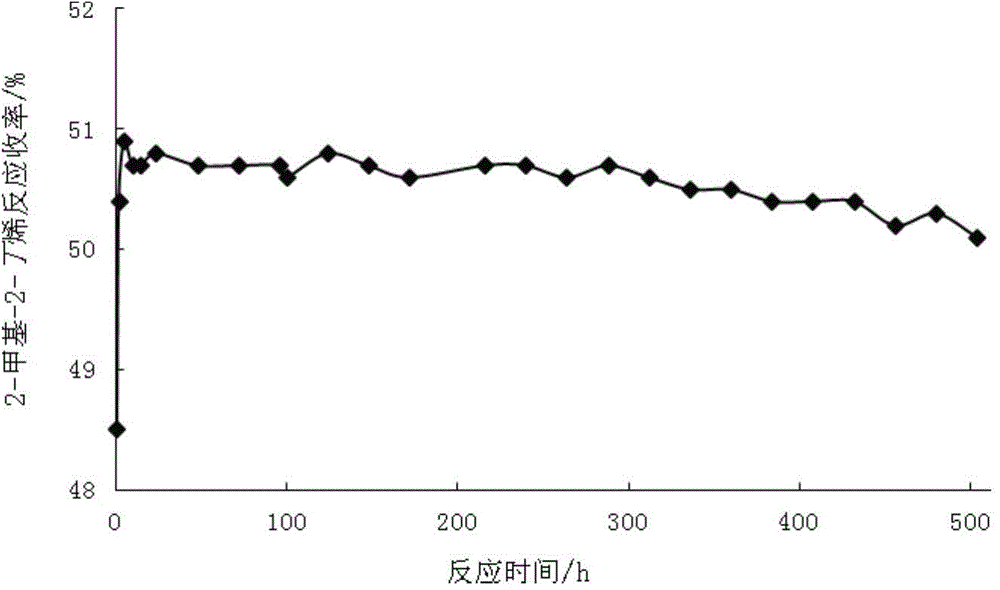

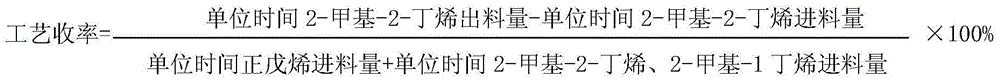

[0043] According to the method provided by the present invention, the ZSM-5 molecular sieve catalyst packed in a first-stage reactor has a silicon-aluminum ratio of 420, a reaction temperature of 415°C, a reaction pressure of normal pressure, a mass percentage of n-pentene of 19.2%, and a mass space velocity of 0.2h -1 , the second-stage reactor is filled with styrene-based macroporous sulfonic acid ion exchange resin, the reaction temperature is 28-30°C, the reaction pressure is 0.5Mpa, and the space velocity is 10h -1 , to investigate the stability of the catalyst reaction, the results are shown in figure 2 ,Depend on figure 2 As can be seen. The technical solution provided by the invention has a longer catalyst activity period and has obvious technical advantages.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com