A system and method for preparing pentafluoroethane

A pentafluoroethane and pipeline technology, applied in the field of systems for preparing pentafluoroethane, can solve the problems of high raw material cost, unachievable yield, difficult separation, etc. The effect of simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

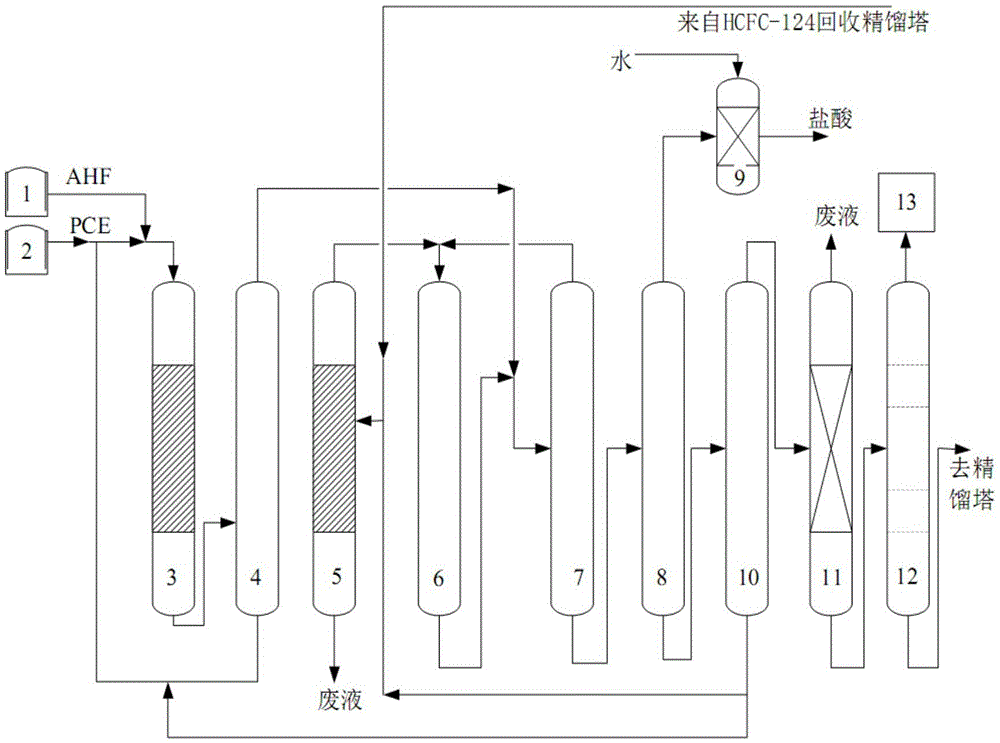

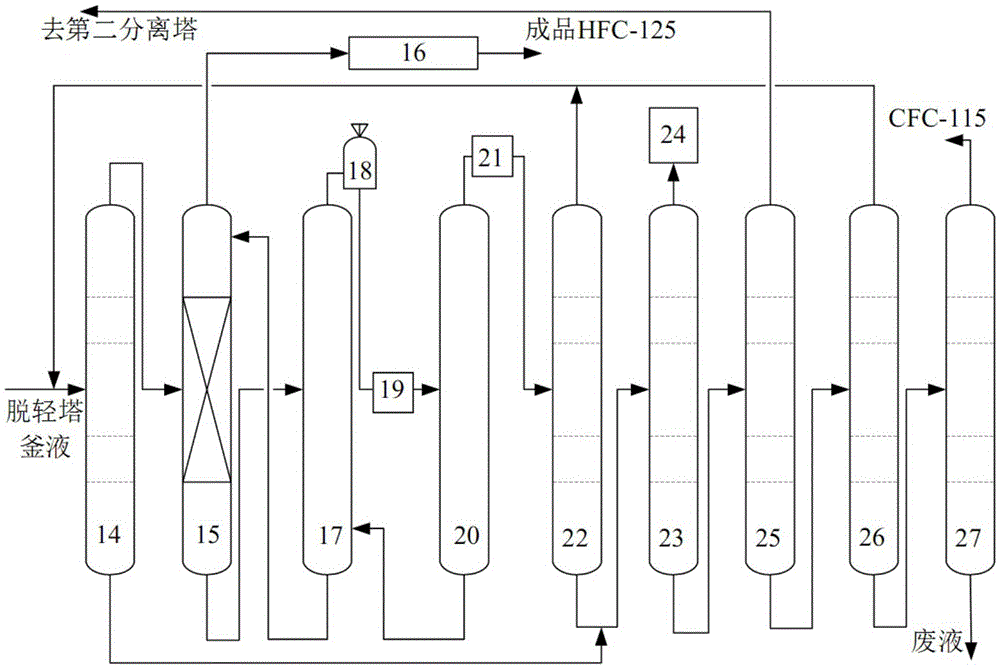

[0016] Such as figure 1The shown system for preparing pentafluoroethane includes an AHF storage tank 1, a PCE storage tank 2, a first reactor 3, a first separation tower 4, a second separation tower 5, a second reactor 6, a condensation tower 7, The third separation tower 8, the HCl absorption tower 9, the fourth separation tower 10, the liquid-phase water alkali washing system 11, the light removal tower 12, the incineration system 13, the rectification tower 14 with raffinate tank and buffer tank, extraction tower 15. Product inspection tank 16, flash tower 17, 1# air bag 18, first-level CFC-115 concentration tank 19, extraction agent recovery tower 20, second-level CFC-115 concentration tank 21, HCFC-124 recovery light removal tower 22, HFC-134a recovery rectification tower 23, HFC-134a purification unit 24, HCFC-124 recovery rectification tower 25, CFC-115 recovery light removal tower 26, CFC-115 recovery rectification tower 27, etc.; wherein AHF storage tank 1 and The PC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com