A method for extracting and separating astaxanthin from Haematococcus pluvialis by a two-phase coupled wall-breaking technology

A technology of Haematococcus pluvialis and Haematococcus pluvialis powder, applied in the direction of organic chemistry, etc., can solve the problems of cumbersome separation and purification process of macroporous resin, difficult recovery of astaxanthin, and many impurities in the extract, and achieve subsequent purification Ease of handling, reduced types and amounts, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

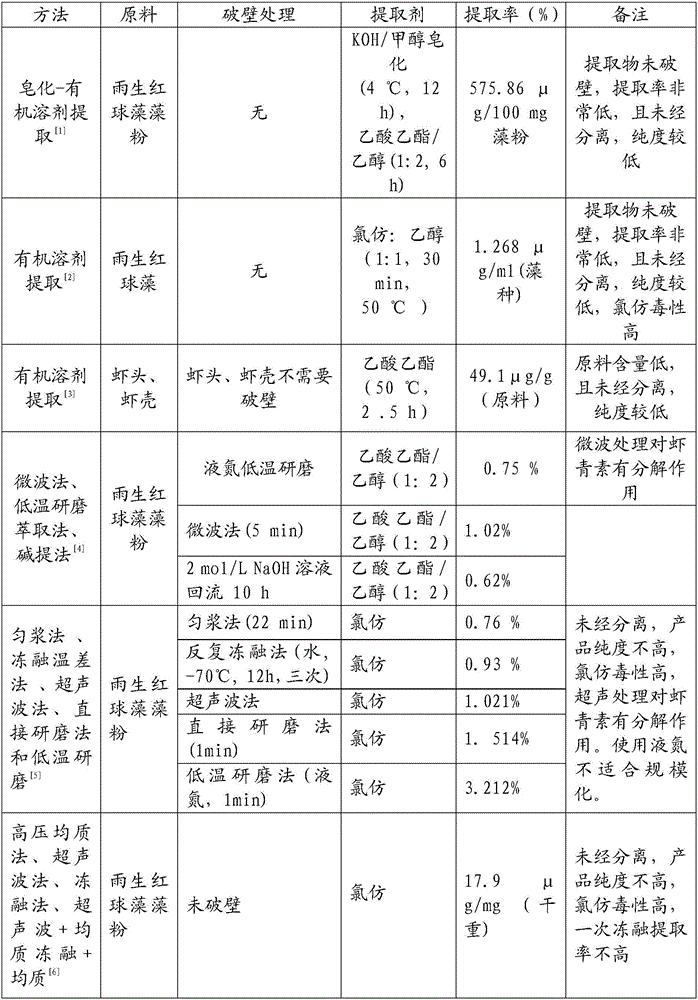

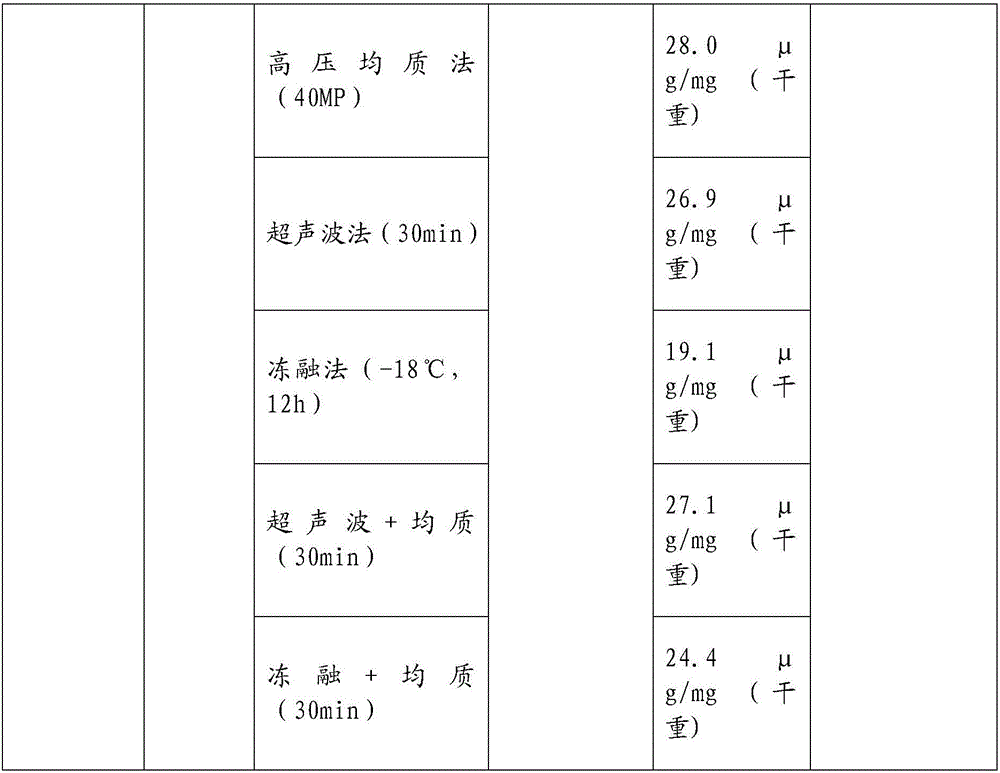

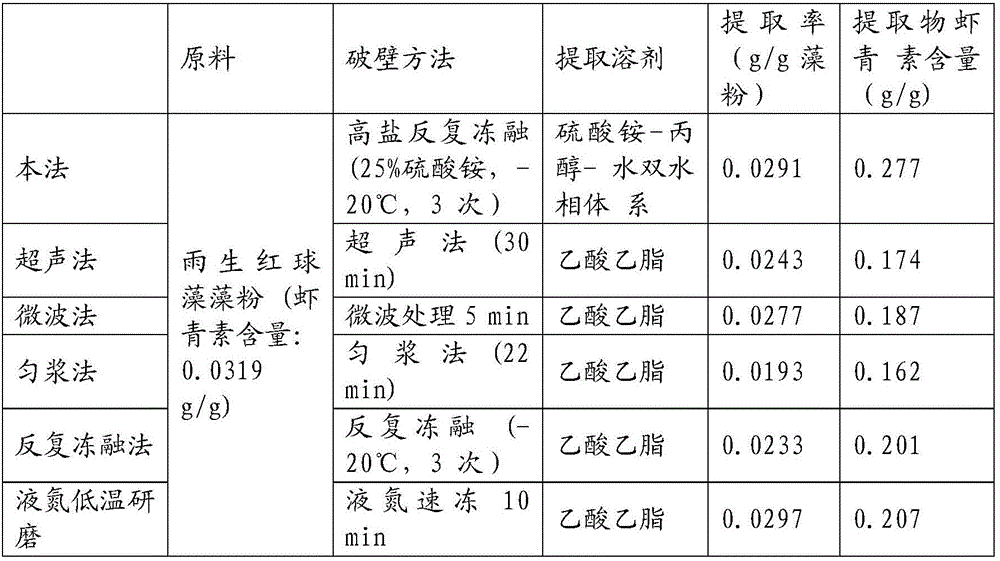

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The freeze-thaw wall-breaking technology of the present invention-a two-phase system integration method for extracting and separating astaxanthin from Haematococcus pluvialis is as follows:

[0039] (1) Add ammonium sulfate solution to the Haematococcus pluvialis powder, the solid-to-liquid ratio of the two is 1:1g / ml, then soak for 0.5h, then place it in a quick-freezer to quickly cool to -15°C, and freeze for 15h;

[0040] (2) After freezing, take it out, thaw at room temperature, then add 3ml of propanol per gram of dry algae powder, place it on a shaker at 180r / min for 40min, and let it stand for 5min;

[0041] (3) After the phase separation is complete, remove the propanol upper phase, put the brine phase and algae powder back into the quick-freezer, repeat the freezing, propanol extraction, and phase separation three times according to steps (1) and (2), Collect all the propanol obtained and evaporate the propanol by vacuum distillation, add ethanol, and vacuum-dr...

Embodiment 2

[0045] The freeze-thaw wall-breaking technology of the present invention-a two-phase system integration method for extracting and separating astaxanthin from Haematococcus pluvialis is as follows:

[0046] (1) Add ammonium sulfate solution to the Haematococcus pluvialis powder, the solid-to-liquid ratio of the two is 1:5g / ml, then soak for 3 hours, then place it in a quick freezer to quickly cool to -25°C, and freeze for 10 hours;

[0047] (2) After freezing, take it out, thaw at room temperature, then add 9ml of propanol per gram of dry algae powder, shake on a shaker at 200r / min for 20min, and let stand for 15min;

[0048] (3) After the phase separation is complete, remove the propanol upper phase, put the brine phase and algae powder back into the quick-freezer, repeat the freezing, propanol extraction, and phase separation three times according to steps (1) and (2), Collect all the propanol obtained and evaporate the propanol by vacuum distillation, add ethanol, and vacuum...

Embodiment 3

[0052] The freeze-thaw wall-breaking technology of the present invention-a two-phase system integration method for extracting and separating astaxanthin from Haematococcus pluvialis is as follows:

[0053](1) Add ammonium sulfate solution to the Haematococcus pluvialis powder, the solid-to-liquid ratio of the two is 1:3g / ml, then soak for 1 hour, then place it in a quick freezer to quickly cool to -20°C, and freeze for 12 hours;

[0054] (2) After freezing, take it out, thaw at room temperature, then add 6ml of propanol per gram of dry algae powder, shake on a shaker at 190r / min for 30min, and let stand for 10min;

[0055] (3) After the phase separation is complete, remove the propanol upper phase, put the brine phase and algae powder back into the quick-freezer, repeat the freezing, propanol extraction, and phase separation three times according to steps (1) and (2), Collect all the propanol obtained and evaporate the propanol by vacuum distillation, add ethanol, and vacuum-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com