A method for producing 5,5-dimethylhydantoin

A technology of dimethyl hydantoin and production process, which is applied in the field of chemical engineering, can solve problems such as environmental pollution, leakage, and difficulty in utilizing ammonia and carbon dioxide in the ternary system, and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

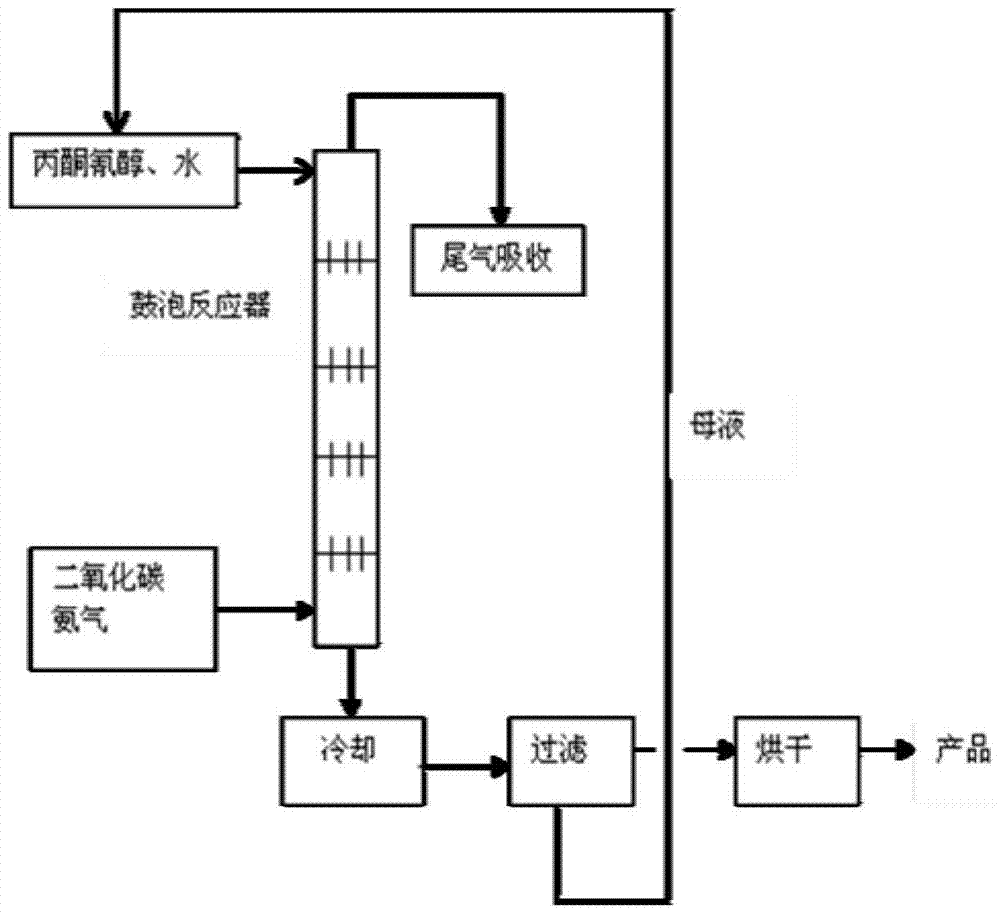

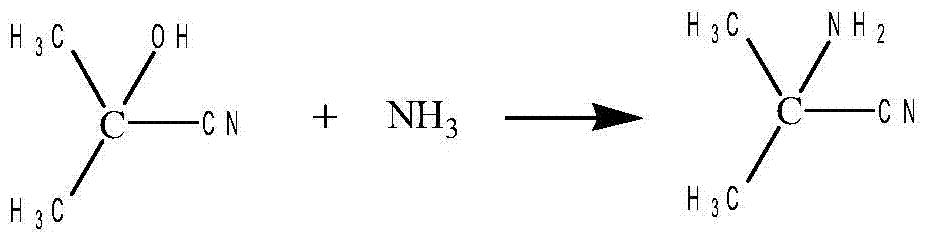

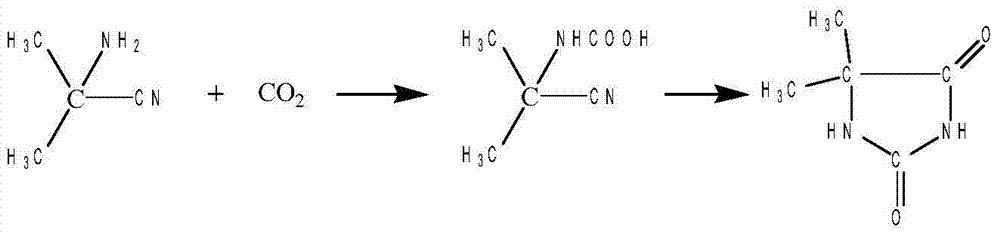

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of 5,5-dimethylhydantoin from the tail gas produced in the production of sodium cyanate by the urea method

[0030] The composition of high-temperature tail gas produced by industrial production of sodium cyanate by urea method is shown in Table 1.1.

[0031] Table 1.1 Composition of waste gas produced by urea method to produce sodium cyanate

[0032]

[0033]After above-mentioned tail gas is removed solid particle through cyclone separator, tail gas enters reactor with the mass flow rate of 120Kg / h, feeds bubble reactor continuously, the mixed solution of acetone cyanohydrin and water, controls acetone cyanohydrin mass flow rate (100Kg / h ~150Kg / h), the mass flow rate of the water in the tower is controlled from 200Kg / h to 300Kg / h, and it is continuously added to the bubbling reactor. The specific flow control of acetone cyanohydrin is determined by ensuring the pH of the solution in the reaction tower = 7.5 to 8.5. When the pH>8.5, increase th...

Embodiment 2

[0034] Example 2 Preparation of 5,5-dimethylhydantoin by using waste gas produced in the process of producing melamine by urea method

[0035] Table 1.2 Composition of waste gas from urea production of melamine

[0036]

[0037] After above-mentioned waste gas is removed solid particle through cyclone separator, tail gas enters reactor with the mass flow rate of 50Kg / h, after the mixing of acetone cyanohydrin and water, pass into bubbling reactor continuously, control acetone cyanohydrin mass flow rate (100Kg / h~ 150Kg / h), the mass flow rate of water in the tower is controlled from 200Kg / h to 300Kg / h, and it is continuously added to the bubbling reactor. The specific flow control of acetone cyanohydrin is determined by ensuring the pH of the solution in the reaction tower = 7.5 to 8.5. When the pH>8.5, increase the flow rate of acetone cyanohydrin. When the pH is less than 7.5, reduce the flow rate of acetone cyanohydrin. The temperature in the reactor is controlled within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com