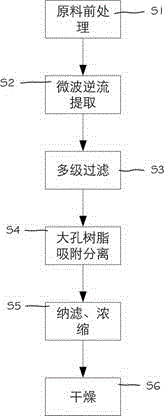

Method for extracting mogroside V from momordica grosvenori

A technology of Mogroside and Luo Han Guo, which is applied in the direction of chemical instruments and methods, glycoside steroids, steroids, etc., can solve the problems of low resin utilization rate, complicated process, low product purity, etc., and achieve the effect of product safety and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] s1 Raw material pretreatment: take 1000 kg of fresh Luo Han Guo fruit, remove impurities, wash, and properly crush, preferably without breaking the Luo Han Guo seeds;

[0037] s2 Microwave countercurrent extraction: Use a microwave countercurrent extraction device to extract the crushed Luo Han Guo. The extraction solvent is deionized water. The material is fed forward and the water is reversed. The flow of material and water is reverse continuous dynamic flow, and the extraction temperature is 90 ℃, the extraction time is 70 min, the microwave power is 800w, and the frequency is 6000MHz. The filter residue is forced to be pushed to the slag outlet by the screw conveyor. Mixed and filtered to obtain the extract;

[0038] s3 multi-stage filtration: Centrifuge the extract obtained in step s2 with a horizontal screw centrifuge at a centrifugal speed of 5000 r / min, then pass through a tubular centrifuge at a centrifugal speed of 14000 r / min, and pass the obtained centrifugate...

Embodiment 2

[0044] s1 Raw material pretreatment: take 1000 kg of fresh Luo Han Guo fruit, remove impurities, wash, and properly crush, preferably without breaking the Luo Han Guo seeds;

[0045] s2 Microwave countercurrent extraction: Use a microwave countercurrent extraction device to extract the crushed Luo Han Guo. The extraction solvent is deionized water. The material is fed forward and the water is reversed. The flow of material and water is reverse continuous dynamic flow, and the extraction temperature is 70 ℃, the extraction time is 50 min, the microwave power is 600w, and the frequency is 8000MHz. The filter residue is forced to be pushed to the slag outlet by the screw conveyor. Mixed and filtered to obtain the extract;

[0046] s3 multi-stage filtration: Centrifuge the extract obtained in step s2 with a horizontal screw centrifuge at a centrifugal speed of 5000 r / min, then pass through a tubular centrifuge at a centrifugal speed of 14000 r / min, and pass the obtained centrifuga...

Embodiment 3

[0052] s1 Raw material pretreatment: take 1000 kg of fresh Luo Han Guo fruit, remove impurities, wash, and properly crush, preferably without breaking the Luo Han Guo seeds;

[0053] s2 Microwave countercurrent extraction: Use a microwave countercurrent extraction device to extract the crushed Luo Han Guo. The extraction solvent is deionized water. The material is fed forward and the water is reversed. The flow of material and water is reverse continuous dynamic flow, and the extraction temperature is 85 ℃, the extraction time is 60 min, the microwave power is 700w, and the frequency is 7000MHz. The filter residue is forced to be pushed to the slag outlet by the screw conveyor. Mixed and filtered to obtain the extract;

[0054] s3 multi-stage filtration: Centrifuge the extract obtained in step s2 with a horizontal screw centrifuge at a centrifugal speed of 5000 r / min, then pass through a tubular centrifuge at a centrifugal speed of 14000 r / min, and pass the obtained centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com