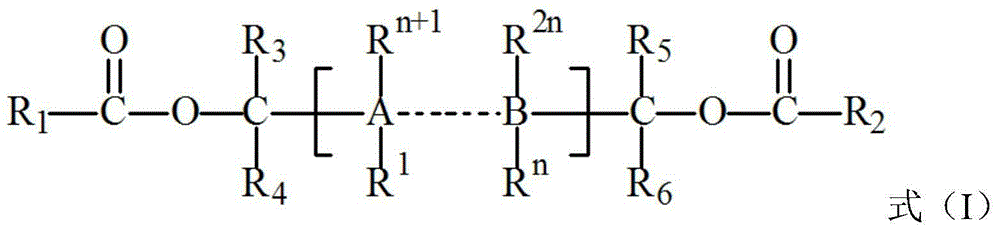

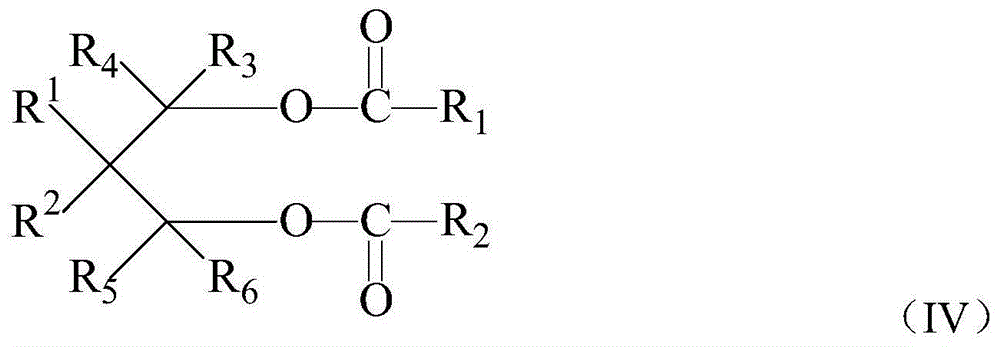

Olefin polymer and preparation method thereof

An olefin polymer and olefin polymerization technology, applied in the field of olefin polymers, can solve the problems of not obtaining high melt index, high isotacticity and wide molecular weight distribution index α-olefin polymer, and achieve the effect of wide molecular weight distribution index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

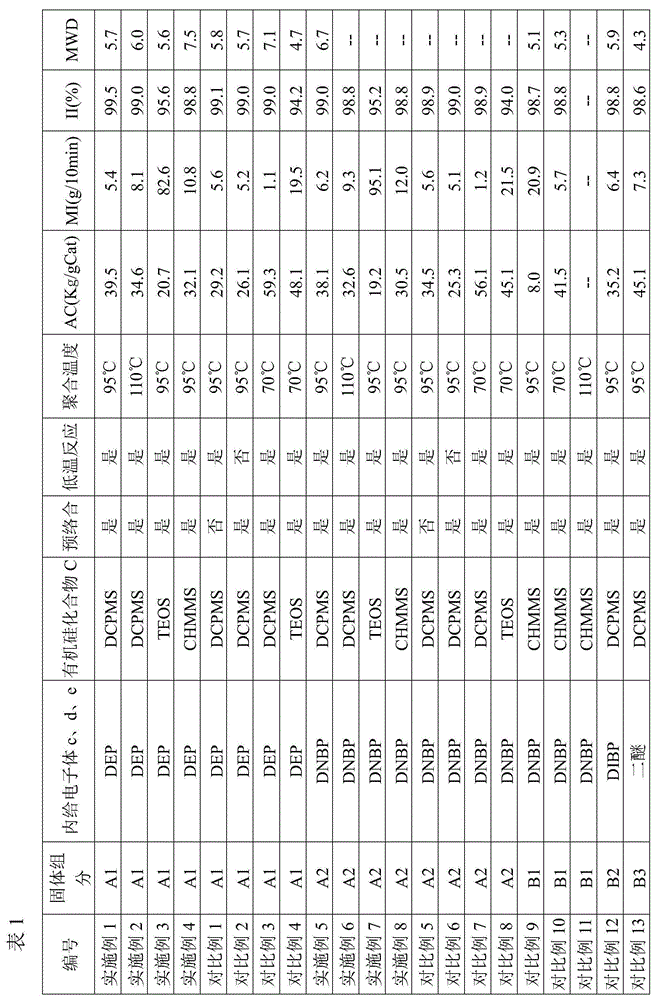

preparation example 1

[0075] This preparation example is used to illustrate the preparation of the solid component A containing magnesium and titanium used in the present invention.

[0076] (a) Add 0.05 moles of anhydrous magnesium chloride, 0.75 moles of toluene, 0.1 moles of epichlorohydrin, and 0.033 moles of tributyl phosphate in sequence in a reaction kettle that has been repeatedly replaced by high-purity nitrogen gas. Under the condition of , react for 1.5 hours, then add 1.9 mmoles of diethyl phthalate (DEP), and react for 1.0 hours to obtain a solution;

[0077](b) Cool the solution obtained in (a) to -28°C, add 0.51 moles of titanium tetrachloride dropwise, and then add 1.4 mmoles of 3,5 heptanediol dibenzoate diluted with 0.1 moles of toluene and 4.4 mmoles of Diphenyldimethoxysilane (DDS), continue to react for 1 hour to form a mixture;

[0078] (c) Gradually raise the temperature of the mixture formed in (b) to 85°C, and solid particles are precipitated during the heating process. A...

preparation example 2

[0081] According to the method of preparation example 1, difference is:

[0082] In (a), replace "1.9 mmol diethyl phthalate (DEP)" with "1.9 mmol di-n-butyl phthalate (DNBP)";

[0083] In (c), "2.6 mmoles of di-n-butyl phthalate (DNBP)" replaces "2.6 mmoles of diethyl phthalate (DEP)". A solid component A2 containing magnesium and titanium is obtained.

preparation example 3

[0085] This preparation is used to illustrate the preparation of the prior art solid components.

[0086] Add 0.05 moles of anhydrous magnesium chloride, 0.88 moles of toluene, 0.05 moles of epichlorohydrin, and 0.05 moles of tributyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 450 rpm and a temperature of 60°C. Add 0.01 moles of Phthalic anhydride, continue to react for one hour, lower the temperature to -28°C, add 0.51 moles of titanium tetrachloride dropwise, gradually raise the temperature to 85°C, add 8.0 mmoles of di-n-butyl phthalate at 80°C, After reaching the temperature, keep the temperature for 1 hour, filter the mother liquor, wash twice with 0.95 mol of toluene, add 0.57 mol of toluene and 0.36 mol of titanium tetrachloride after filtering, keep the temperature at 110°C for 2 hours, repeat the treatment once after filtering, and hexane 5 After several washings and drying, the solid component B1 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com