Plant extract and method for cross-linking collagen by using plant extract as biological cross-linker

A technology of plant extract and biological cross-linking agent is applied in the field of plant extract and its use as a biological cross-linking agent to cross-link collagen to achieve the effects of improving stability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

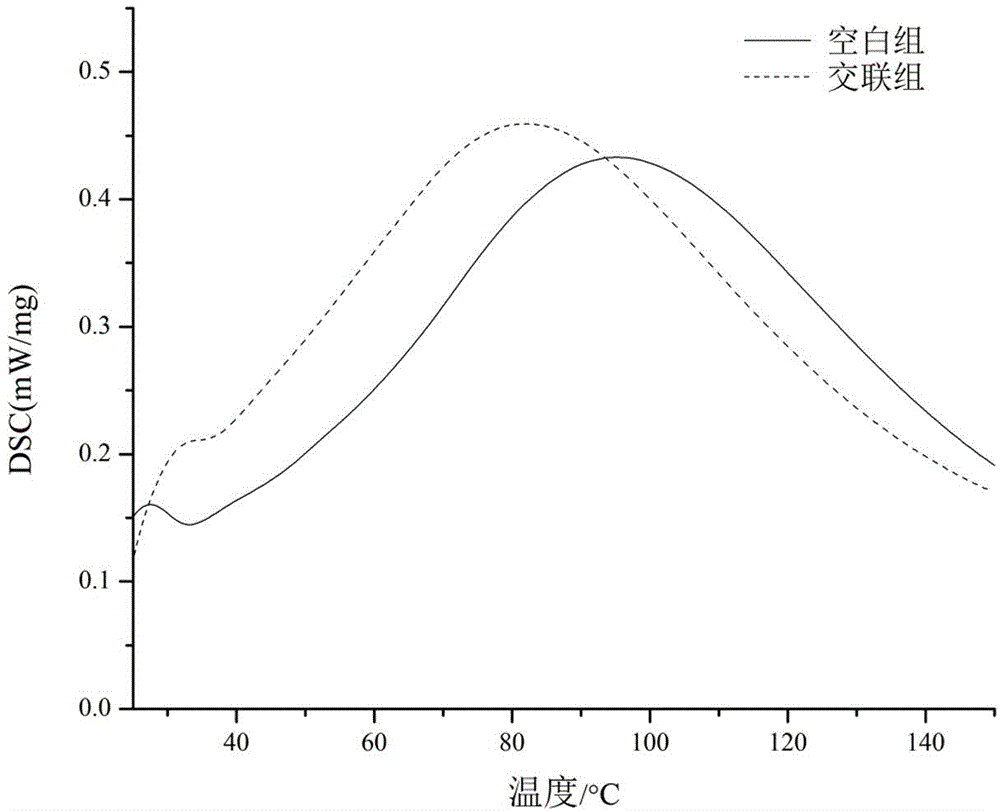

Image

Examples

Embodiment 1

[0044] A plant extract, Amomum chinensis extract, contains polyphenol active ingredients, and Amomum chinensis extract is in the form of dry powder. The specific preparation method steps of Amomum chinensis extract are as follows:

[0045] In the first step, the amomum is washed with deionized water, dried at 60°C, and crushed to 80 mesh with a pulverizer;

[0046] In the second step, the pulverized amomum powder is leached in 50% ethanol solution, the ratio of feeding material to liquid is 1:15, the leaching temperature is 60°C, the leaching time is 2 hours, and continuous stirring is required during the leaching process. ;

[0047] In the third step, the leaching solution and the residue are filtered and separated with a 0.5 μm membrane;

[0048] In the fourth step, the leaching solution is concentrated under reduced pressure, the temperature is 60°C, and the vacuum degree is 0.07MPa;

[0049] In the fifth step, the concentrated plant extract solution is quickly frozen at...

Embodiment 2

[0057] A plant extract, amomum extract, contains polyphenol active ingredients, and the amomum extract is in the form of dry powder. The specific preparation method steps of the amomum extract are as follows:

[0058] In the first step, the amomum is washed with deionized water, dried at 70°C, and crushed to 120 mesh with a pulverizer;

[0059] In the second step, the pulverized amomum powder is leached in 75% ethanol solution, the ratio of feeding material to liquid is 1:20, the leaching temperature is 50°C, and the leaching time is 4 hours. During the leaching process, constant stirring is required. ;

[0060] In the third step, the extract and residue are centrifuged at a speed of 5000r / min, and the supernatant is taken;

[0061] The fourth step is to concentrate the extract under reduced pressure at a temperature of 50°C and a vacuum of 0.08MPa;

[0062] In the fifth step, the obtained concentrated plant extract solution is frozen at -18°C, and after freezing, a dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com