Low-emission long glass fiber reinforced polypropylene composite and preparation method thereof

A composite material and polypropylene technology, which is applied in the processing field of polypropylene composite materials, can solve problems such as the inability to achieve volatile substance suppression, and achieve the effects of broad market prospects and market benefits, low emission performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

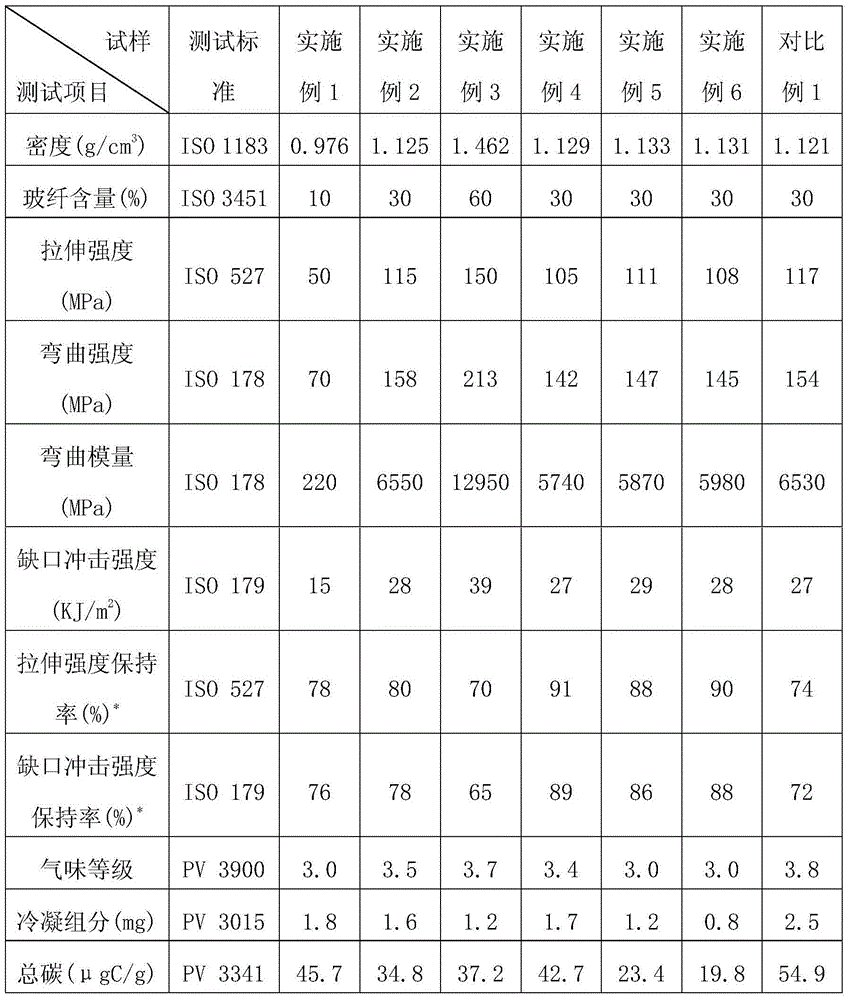

Examples

Embodiment 1

[0029] In this example, the low emission long glass fiber reinforced polypropylene composite material is prepared as follows:

[0030]First, 85.5KG of polypropylene PP PT231 (melt index is 26g / 10min), 2KG of anionic layered compound FM-300, 1KG of compatibilizer maleic anhydride grafted polypropylene BONDYRAM 1001CN (grafting rate 0.9 %), 0.6KG of processing aid N, N-ethylene bis stearic acid amide, 0.9KG of heat stabilizer after mixing, join in twin-screw extruder and carry out high-temperature melting, the temperature of twin-screw extruder Set it at 250°C to fully plasticize and melt the mixed material; then, input the obtained high-temperature melt into the dipping mold, and set the die head temperature of the dipping mold at 250°C; then, put 10KG The alkali-free continuous long glass fiber ER4305PM-2400 is transported into the impregnation mold. After the alkali-free continuous long glass fiber is dispersed and completely impregnated by the high-temperature melt, it is pu...

Embodiment 2

[0032] In this example, the low emission long glass fiber reinforced polypropylene composite material is prepared as follows:

[0033] First, 65KG of polypropylene PP PT231 (melt index is 26g / 10min), 0.5KG of anionic layered compound FM-300, 3KG of compatibilizer maleic anhydride grafted polypropylene BONDYRAM 1001CN (grafting rate 0.9 %), 0.6KG of processing aid N, N-ethylene bis stearic acid amide, 0.9KG of heat stabilizer after mixing, join in twin-screw extruder and carry out high-temperature melting, the temperature of twin-screw extruder Set it at 280°C to fully plasticize and melt the material; then, input the obtained high-temperature melt into the dipping mold, and set the die head temperature of the dipping mold at 300°C; The alkali-free continuous long glass fiber ER4305PM-2400 is transported into the impregnation mold. After the alkali-free continuous long glass fiber is dispersed and completely impregnated by the high-temperature melt, it is pulled out of the impr...

Embodiment 3

[0035] In this example, the low emission long glass fiber reinforced polypropylene composite material is prepared as follows:

[0036] First, graft polypropylene BONDYRAM 1001CN (grafting rate of 0.9%), the processing aid erucamide of 0.1KG, the heat stabilizer of 0.2KG after mixing evenly, join in the twin-screw extruder and carry out high-temperature melting, the temperature setting of the twin-screw extruder is 280 ℃, to The material is fully plasticized and melted; then, the obtained high-temperature melt is input into the impregnation mold, and the die head temperature of the impregnation mold is set at 330°C; then, 60KG of alkali-free continuous long glass fiber E6DR17-2400 -362KF is conveyed into the impregnation mold, the alkali-free continuous long glass fiber is dispersed and completely impregnated by the high-temperature melt, and then pulled out of the impregnation mold; finally, the impregnated long glass fiber is cooled and pelletized, and the particle length Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com