Polyvinyl chloride grade-A fireproof material and preparation method thereof

A technology of polyvinyl chloride and fireproof materials, applied in the field of materials, can solve problems such as the improvement of fireproof grade, and achieve the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

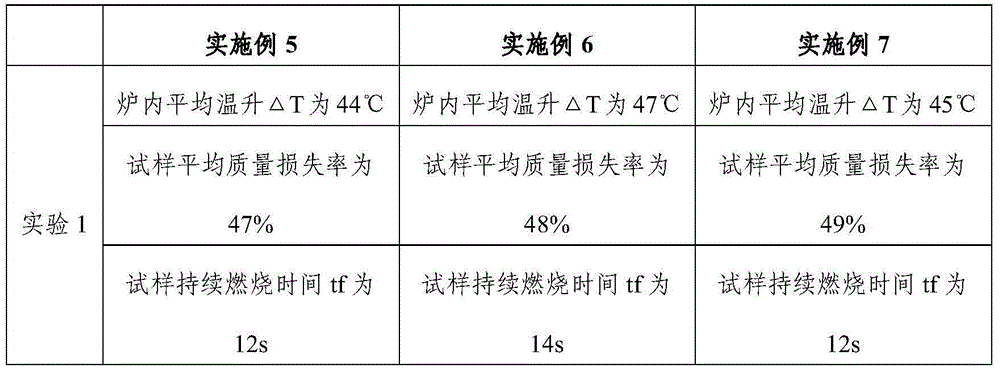

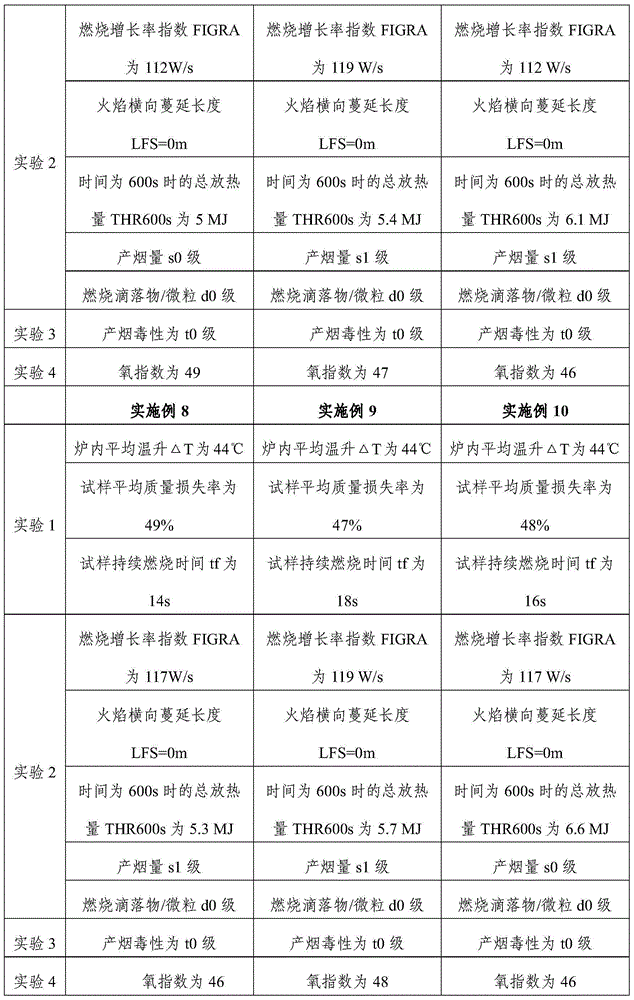

Examples

Embodiment 1

[0029] The flame-retardant polyether of this embodiment is composed of the following raw materials: 1 part of rare earth fluoride, 0.5 parts of butylene oxide, 1.5 parts of catalyst, and 1.5 parts of polytetrafluoroethylene; wherein, 1.5 parts of catalyst is composed of the following components: 0.6 parts Methanol, 0.5 parts of silicone oil, 0.3 parts of sodium silicate, 0.1 parts of sodium bicarbonate.

[0030] The preparation method of flame retardant polyether in the present embodiment comprises the following steps:

[0031] (1) Put the fluoride, butylene oxide, catalyst, and polytetrafluoroethylene of the proportioning amount into a cylindrical airtight reaction vessel (arc generator is set in the reaction vessel, and microwave is set at the 1.5m height of the reactor wall. Generator), after vacuuming, fill it with non-oxidizing gas, so that the pressure in the container is 75MPa;

[0032] (2) Under the conditions of a temperature of 560°C, a voltage of 15,000 volts, and ...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that the fluoride used in embodiment 2 is sodium fluoride.

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is that in embodiment 3, 3 parts of polytetrafluoroethylene are selected for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com