Imidazoline polyether-ether-ketone/sulfonated polyether-ether-ketone blended membrane as well as preparation method and application thereof

A technology of sulfonated polyether ether ketone and imidazolidinated polyether, which is applied in the field of fuel cell ion exchange membranes, can solve the problems of polymer membrane stability degradation and the inability to use fuel cells, etc., and achieves a simple and controllable process and conditions Gentle, readily available ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1. Preparation of imidazolidinated polyether ether ketone / sulfonated polyether ether ketone blend membrane, the steps are as follows:

[0029] Step 1. Preparation of sulfonated polyetheretherketone: Dissolve 28g of polyetheretherketone in 200mL of concentrated sulfuric acid at 25 degrees Celsius, heat up to 65 degrees Celsius, and react for 6.8 hours. After that, sulfonated polyether ether ketone is precipitated in water. 57%, wash with water until the filtrate is neutral, dry it for use.

[0030] Step 2. Preparation of chloromethylated polyether ether ketone: Dissolve 2 g of polyether ether ketone in 120 mL of concentrated sulfuric acid at -10°C. After the polyether ether ketone was completely dissolved, 40 mL of a chloromethyl octyl ether chloroform solution with a mole fraction of 70% was added, and reacted at 0 degrees Celsius for 60 min to obtain chloromethylated polyether ether ketone.

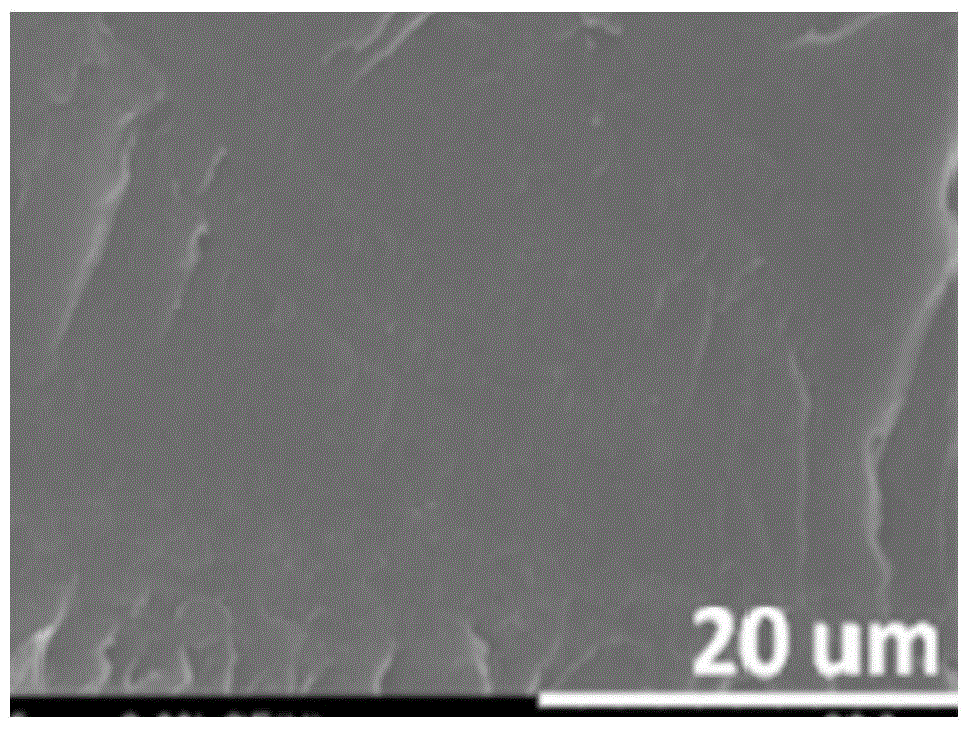

[0031] Step 3. Dissolve 0.0455g of sulfonated polyetheretherketone p...

Embodiment 2

[0032] Example 2. Preparation of imidazolidinated polyether ether ketone / sulfonated polyether ether ketone blend membrane, the steps are as follows:

[0033] Step 1 and step 2 are the same as described in Example 1 to prepare sulfonated polyetheretherketone and chloromethylated polyetheretherketone.

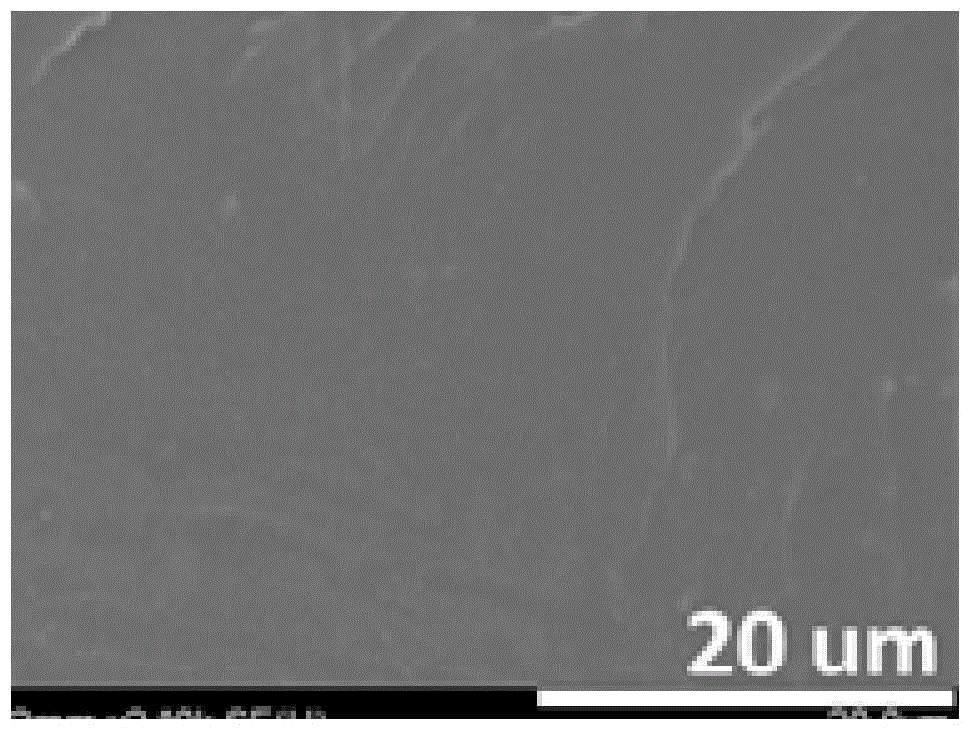

[0034] Step 3. Dissolve 0.0910 g of the sulfonated polyether ether ketone prepared in Example 1 with 4 mL of 1-methylimidazole to obtain solution A; The obtained chloromethylated polyetheretherketone was obtained as solution B; 4mL of solution A and 6mL of solution B were taken and mixed uniformly under vigorous stirring to obtain a casting solution, which was cast on a glass plate and placed in drying in an oven to obtain the imidazolidinated polyether ether ketone / sulfonated polyether ether ketone blend film. figure 2 It is a partial SEM image of the cross-section of the blend film prepared in Example 2.

Embodiment 3

[0035] Example 3. Preparation of imidazolidinated polyetheretherketone / sulfonated polyetheretherketone blend membrane, the steps are as follows:

[0036] Step 1 and step 2 are the same as described in Example 1 to prepare chloromethylated polyetheretherketone and sulfonated polyetheretherketone.

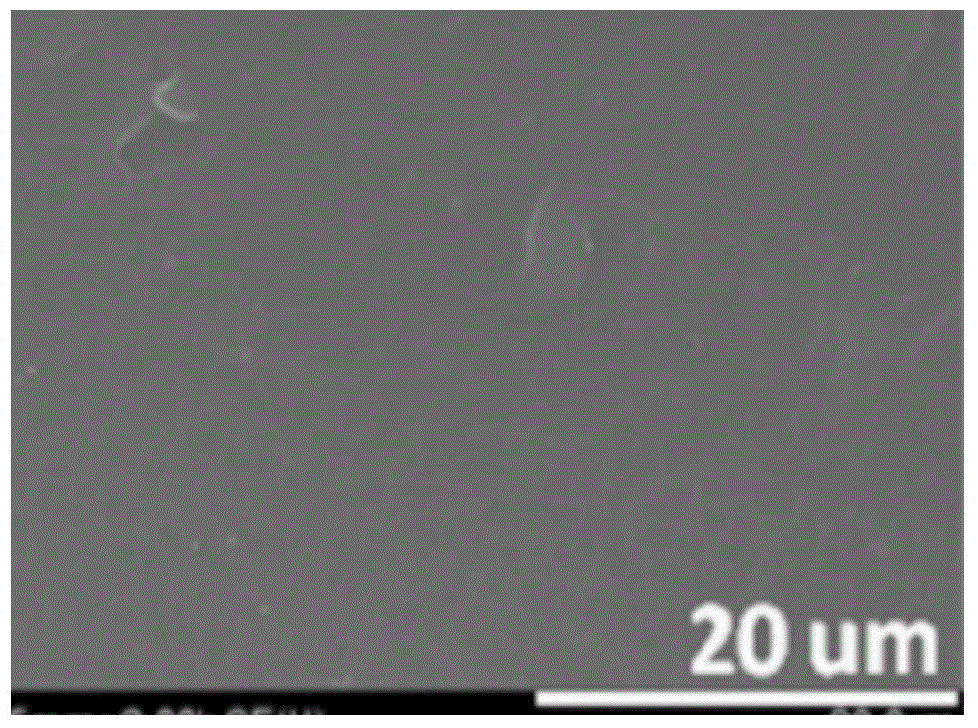

[0037]Step 3: Dissolve 0.1625 g of the sulfonated polyetheretherketone prepared in Example 1 with 4 mL of 1-methylimidazole to obtain solution A; The obtained chloromethylated polyetheretherketone was obtained as solution B; 4mL of solution A and 6mL of solution B were taken and mixed uniformly under vigorous stirring to obtain a casting solution, which was cast on a glass plate and placed in drying in an oven to obtain the imidazolidinated polyether ether ketone / sulfonated polyether ether ketone blend film. image 3 It is a partial SEM image of the cross-section of the blend film prepared in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com