Processing Technology of Pitaya Vinegar with Red Color

A processing technology, the technology of pitaya, applied in the field of pitaya vinegar processing technology, can solve the problem of destroying the color of the product, and achieve the effects of good health care, long shelf life and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

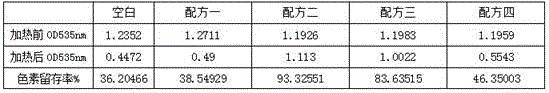

Image

Examples

Embodiment 1

[0023] Embodiment 1 Pitaya vinegar processing technology 1 with red color and luster

[0024] The process includes five parts: raw material processing, low-temperature alcohol fermentation, low-temperature acetic acid fermentation, low-temperature aging, and low-temperature sterilization and filling. The specific steps are as follows:

[0025] (1) Raw material treatment: first wash the dragon fruit surface with deionized water containing 0.1% detergent, and then soak it in a sodium hexametaphosphate solution with a mass fraction of 0.01% for 5 minutes to thoroughly wash off the residual metal ions on the surface Cutting the dragon fruit, separating its skin and flesh, adding its quality of 0.05% D-isoascorbic acid and 0.0001% EDTA-Na in the pulp or pericarp, and beating.

[0026] (2) Low-temperature alcohol fermentation: add sugar, adjust the solid content to 15%, insert and screen the fruit wine yeast produced by Angel Yeast Co., Ltd., the model is RW; carry out fermentation,...

Embodiment 2

[0035] Embodiment 2 Pitaya vinegar processing technology 2 with red color and luster

[0036] The process includes five parts: raw material processing, low-temperature alcohol fermentation, low-temperature acetic acid fermentation, low-temperature aging, and low-temperature sterilization and filling. The specific steps are as follows:

[0037] (1) Raw material treatment: first wash the dragon fruit surface with deionized water containing 0.5% detergent, and then soak it in a sodium hexametaphosphate solution with a mass fraction of 0.05% for 8 minutes to thoroughly wash off the residual metal ions on the surface Cutting the dragon fruit, separating its skin and flesh, adding its quality of 0.5% D-isoascorbic acid and 0.0005% EDTA-Na in the pulp or pericarp, and beating.

[0038] (2) Low-temperature alcoholic fermentation: add sugar, adjust the solid content to 15%, insert the selected fruit wine yeast produced by Angel Yeast Co., Ltd., the model is RW; the mother is fermented,...

Embodiment 3

[0046] The red dragon fruit vinegar processing technology 3 of embodiment 3 color and luster

[0047] The process includes five parts: raw material processing, low-temperature alcohol fermentation, low-temperature acetic acid fermentation, low-temperature aging, and low-temperature sterilization and filling. The specific steps are as follows:

[0048] (1) Raw material treatment: first wash the dragon fruit surface with deionized water containing 1.0% detergent, and then soak it in a sodium hexametaphosphate solution with a mass fraction of 0.1% for 10 minutes to thoroughly wash off the residual metal ions on the surface Cutting the dragon fruit, separating its skin and flesh, adding its quality of 0.5% D-isoascorbic acid and 0.001% EDTA-Na in the pulp or pericarp, and beating.

[0049] (2) Low-temperature alcoholic fermentation: add sugar, adjust the solid content to 20%, insert the selected fruit wine yeast produced by Angel Yeast Co., Ltd., the model is RW; carry out ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com