A kind of yeast agent and its use and method for producing ethanol

A technology of yeast and yeast, which is applied in the field of yeast inoculum and ethanol production, can solve the problems of being unable to become the dominant strain of lignocellulosic ethanol, inhibiting cell growth and fermentation performance, and inhibiting sensitive components, etc., to achieve strong practicability and sugar The effect of high utilization rate and stable genetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

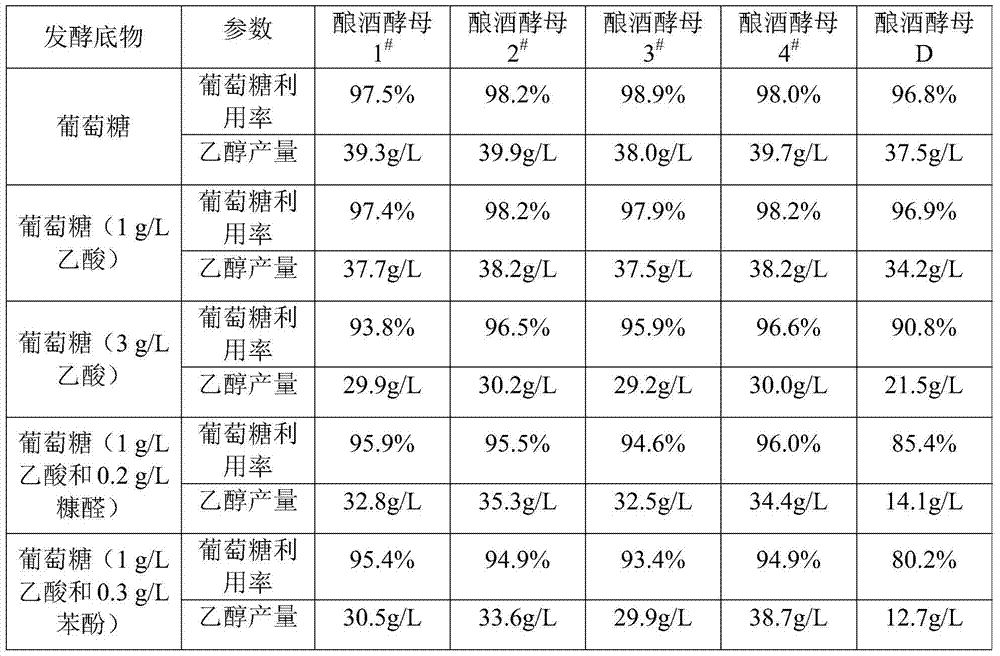

[0022] According to a preferred embodiment of the present invention, the preparation method of the yeast agent is as follows: inoculating Saccharomyces cerevisiae RIPP-06, Saccharomyces cerevisiae RIPP-01 and Saccharomyces cerevisiae RIPP-07 into a yeast medium for culturing. The yeast preparation prepared according to the preferred embodiment of the present invention has better fermentation performance.

[0023] Wherein, there is no special limitation to the total inoculation amount of above-mentioned three kinds of Saccharomyces cerevisiae, can be conventional inoculum amount, preferably, with respect to the total sugar of every gram in described yeast culture medium, the total inoculum amount of Saccharomyces cerevisiae is 10 3 -10 8 For each yeast cell, more preferably, the ratio of the inoculation amount of Saccharomyces cerevisiae RIPP-06, Saccharomyces cerevisiae RIPP-01 and Saccharomyces cerevisiae RIPP-07 is 1:0.5-2:0.5-2. There is no particular limitation on the yea...

preparation Embodiment 1

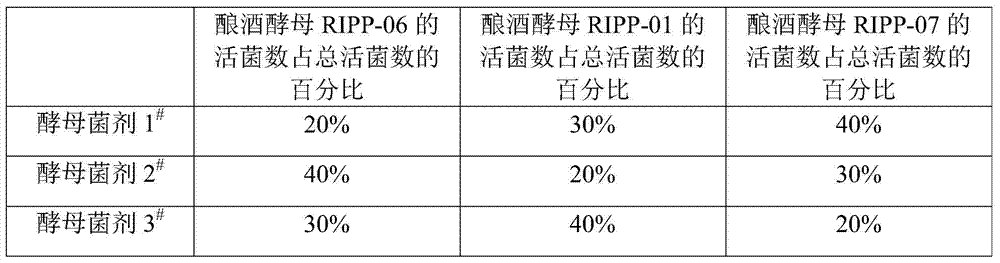

[0040] Prepare the saccharomyces agent according to the proportion shown in Table 1.

[0041] Table 1

[0042]

preparation Embodiment 2

[0044] Saccharomyces cerevisiae RIPP-06, Saccharomyces cerevisiae RIPP-01 and Saccharomyces cerevisiae RIPP-07 were inoculated into yeast medium (ie seed medium without acetic acid) for cultivation (cultivation temperature was 30°C and cultivation time was 50h), Saccharomyces cerevisiae The total inoculum size is 10 5 yeast cells (relative to the total sugar per gram in the yeast culture medium), the inoculum ratio of S. cerevisiae RIPP-06, S. cerevisiae RIPP-01 and Saccharomyces cerevisiae RIPP-07 is 1:1:1 to obtain yeast Agent 4 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com