Lactococcus lactis sub-specie lactis strain capable of producing high-yield lactic acid and application thereof

A technology of Lactococcus lactis and Lactic acid subspecies, applied in the application, bacteria, dairy products and other directions, can solve the problems of poor cheese quality, slow acid production by starter strains, etc., and achieves strong acid production capacity, excellent fermentation performance, and good maturity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

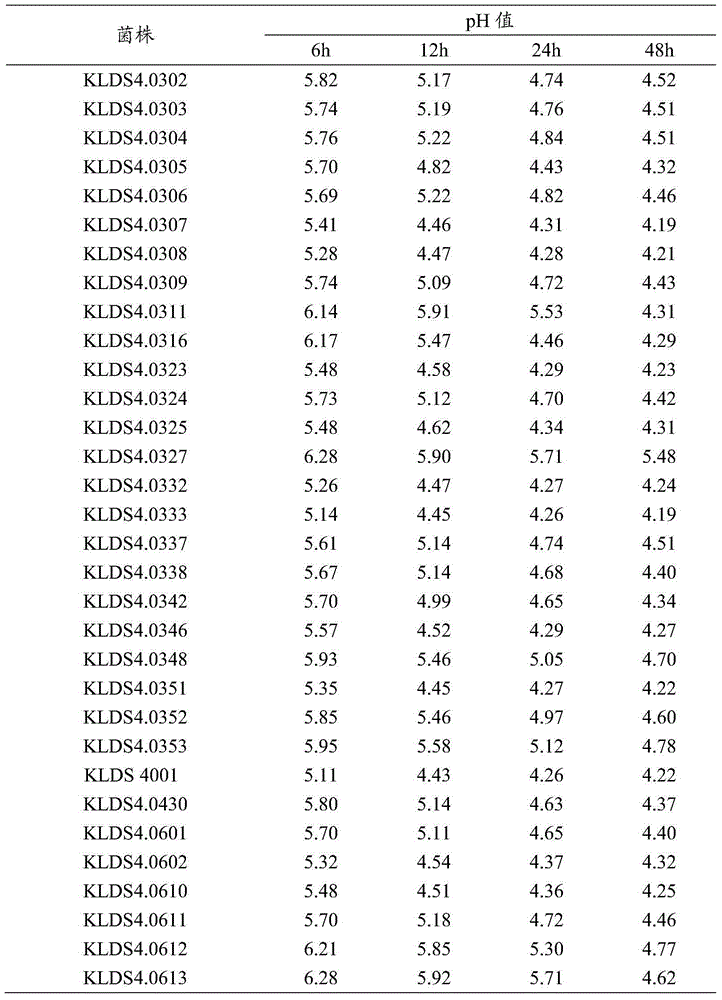

[0034] Example 1 Screening of wild-type high-acid-producing Lactococcus lactis

[0035] (1) screening

[0036] After activating 32 strains of Lactococcus lactis in the laboratory for 3 times, inoculate 1% in 10% (w / v) sterilized skim milk medium, and measure the pH value at 6, 12, 24 and 48 hours respectively , and use this as an index to screen out strains with high acid production performance.

[0037] (2) Screening results

[0038] The test results of the acid production ability of 32 strains of Lactococcus lactis are shown in Table 1. Strain KLDS4001 exhibited the highest acid production capacity, and the pH value was lower than 5.2 after 6 hours of fermentation, 4.43 at 12 hours of fermentation, and reached 5.22 at 48 hours. At the same time, the fermented milk of the KLDS4001 strain has a good taste, quick coagulation, uniform and delicate texture, good tissue structure, and normal whey precipitation, which is suitable for the production of cheese.

[0039] Table 1 C...

Embodiment 2

[0043] The preparation of embodiment 2 composite leavening agent

[0044] (1) Strain activation: Reconstitute skim milk powder into skim milk at a ratio of 10%, and then sterilize it at 115°C for 15 minutes. The vitality is fully restored.

[0045] (2) Preparation of starter: Reconstitute skim milk powder into skim milk at a ratio of 10%, and then sterilize it at 115°C for 15 minutes. milk, and store in the refrigerator for later use.

[0046] (3) Preparation of compound starter: mix starters prepared by Lactococcus lactis subsp. lactis KLDS4001 and Lactococcus lactis subsp. cremoris KLDS4002 at a volume ratio of 1:1 as a mixed starter. Lactococcus lactis subsp. lactic acid KLDS4001 and Lactococcus lactis subsp. cremoriferum KLDS4002 both reached 10 live bacteria counts as measured by live bacteria technology. 9 cfu / mL.

Embodiment 3

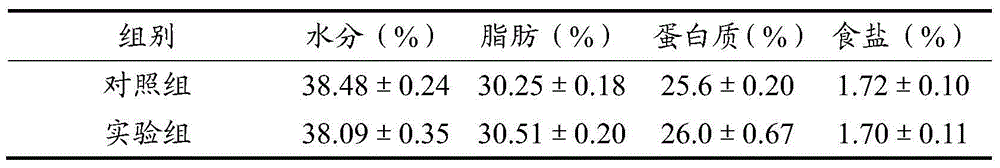

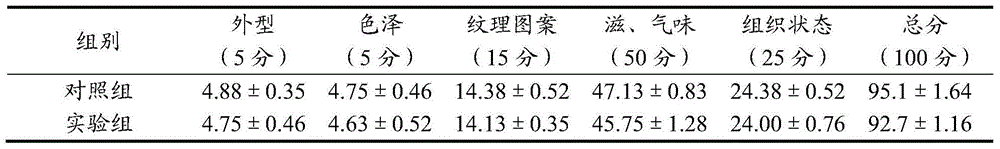

[0047] Embodiment 3: the application of bacterial strain in cheddar cheese

[0048] 1.1 Preparation of cheddar cheese

[0049] (1) Raw milk pretreatment: 10kg of raw milk is filtered and poured into a cheese tank that has been sterilized beforehand, sterilized at 63°C for 30 minutes, and then cooled to 31°C;

[0050] (2) Addition of starter, calcium chloride and rennet: add 200mL of compound starter, add 0.2g of direct-throwing starter to the control cheese, and ferment at 31°C for 30-40min under temperature control until the milk acidity is 0.20%- 0.22%, add 2gCaCl 2 , 0.3g rennet, after stirring evenly, let the curd stand;

[0051] (3) Cutting, heating and stirring and removing whey: 30 minutes after adding rennet, test the clot strength with a knife, and test once every 2 minutes. The method of testing the curd strength is to insert a knife into the clot obliquely for 4cm. When it is lifted up, if the cracks are neat, no small pieces of clot remain and the whey is transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com