Multi-anode lithium metal electrolytic bath

A lithium metal and electrolytic cell technology, applied in the field of electrolytic cells, can solve the problems of accelerating the fracture of graphite anodes, reducing the operating life of anode graphite, and increasing the operating costs of electrolytic cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

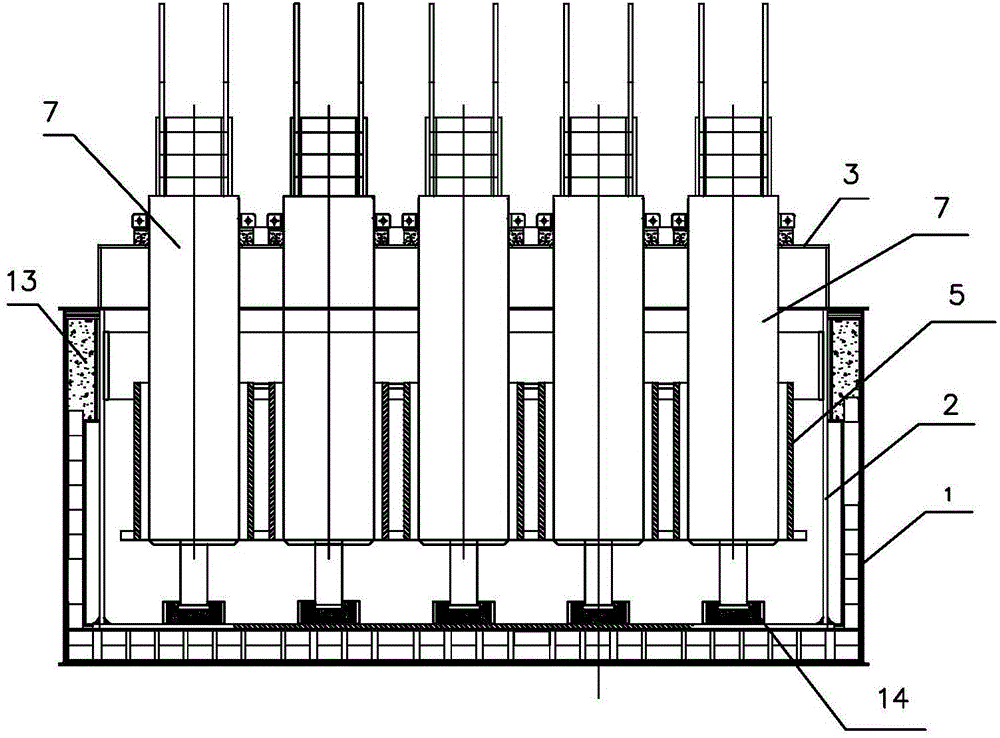

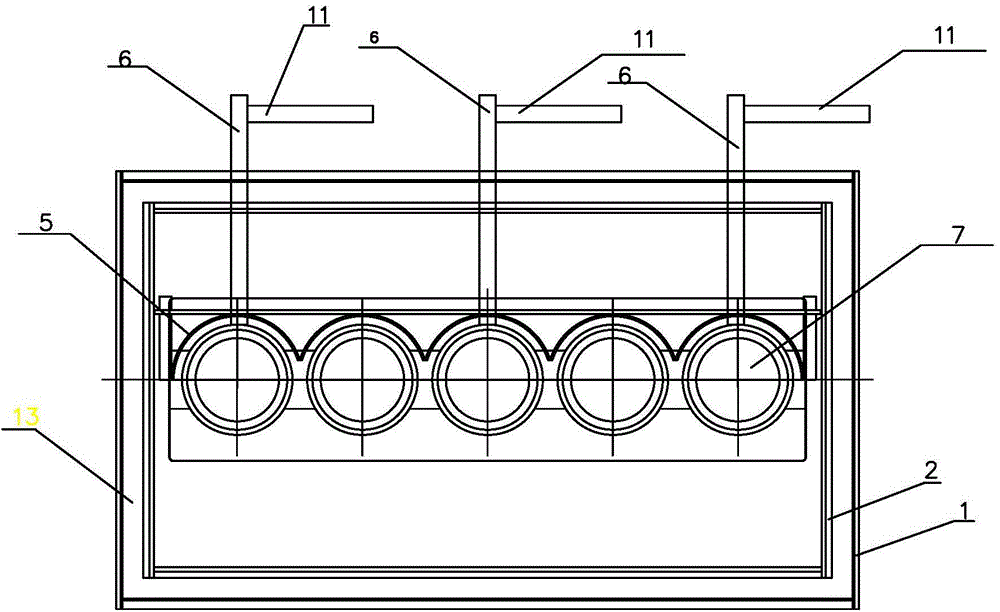

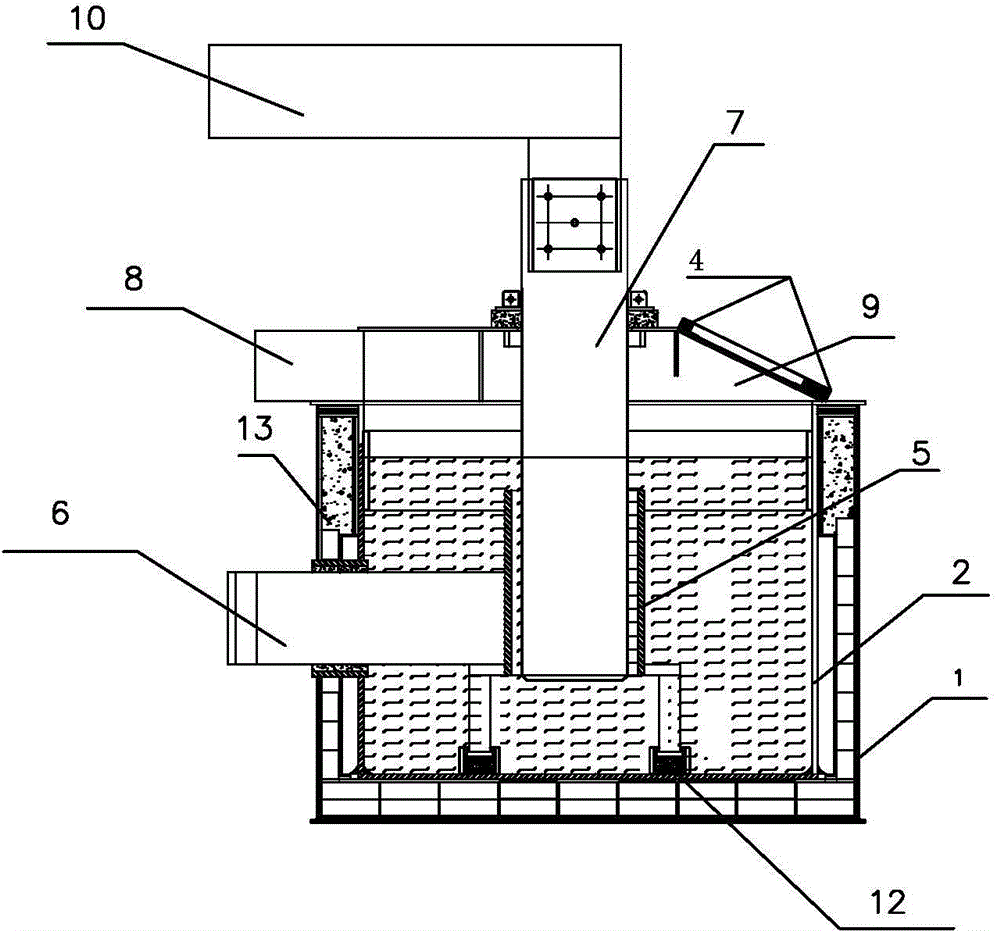

[0027] The following with attached Figure 1 to Figure 5 A multi-anode metal lithium electrolytic cell of the present invention will be further described in detail.

[0028] A kind of multi-anode metal lithium electrolyzer of the present invention, please refer to Figure 1 to Figure 5 , comprising an outer cell body 1, an inner liner body 2, a cathode 5, an anode 7, and a cell cover 3 covering the top of the outer cell body 1 and the inner liner body 2 to form a cavity for accommodating the electrolyte, the cell The cover 3 is provided with a chlorine discharge port 8 for chlorine gas discharge and a lithium discharge port 9 for metal lithium discharge, the cathode 5 is arranged around the outside of the anode 7, and the anode 7 is evenly distributed on the inner liner 2, the cathode 5 is connected to the cathode busbar 11, the anode 7 is connected to the anode busbar 10, the cathode 5 is fixed inside the lining body 2, and the number of the anode 7 is the same as that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com