A kind of environment-friendly sweater antibacterial finishing agent and preparation method thereof

A technology of antibacterial finishing and wool sweater, applied in fiber processing, textiles and papermaking, animal fibers, etc., can solve the problems of poor antibacterial effect, environmental damage, human injury, etc., to improve antibacterial performance, good antibacterial rate, reducing the effect of fungal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

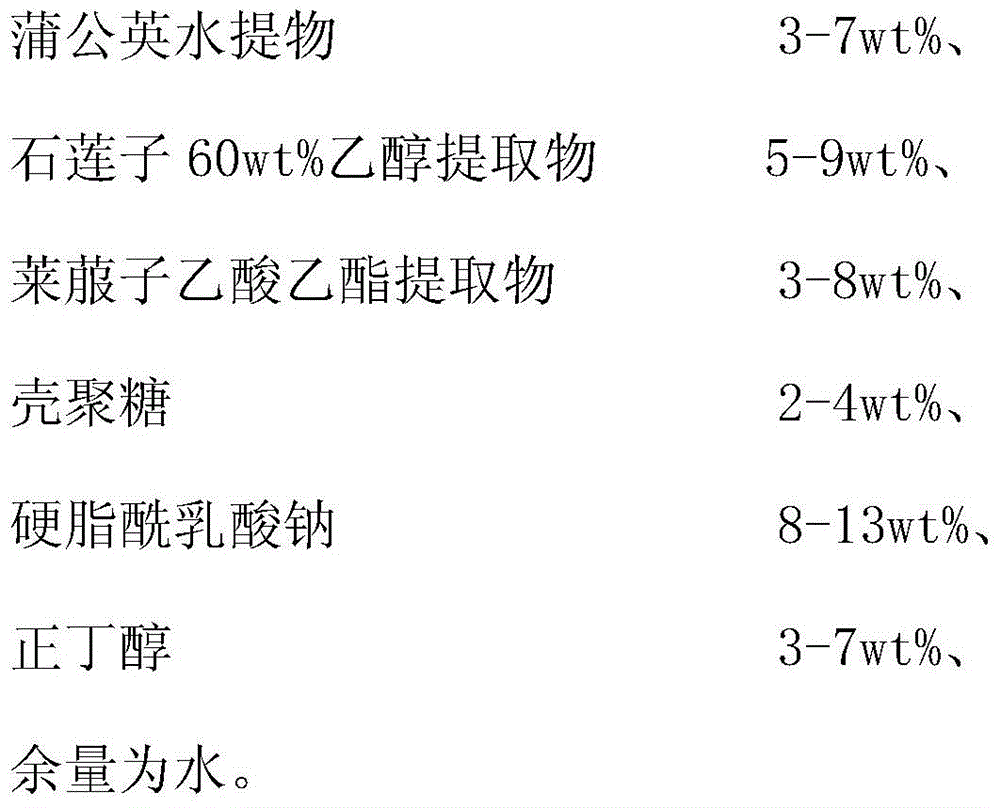

Embodiment 1

[0026] (1) Take dandelion, stone lotus seeds, and radish seeds, and carry out hot air drying respectively at a drying temperature of 80° C. After drying, dandelion, stone lotus seeds, and radish seeds are respectively crushed; (2) Take the crushed dandelions, and stir and extract dandelions with water , centrifugal separation after extraction, collecting the supernatant, concentrating the supernatant, and concentrating the water extract of dandelion; (3) taking the pulverized Shilian seeds, stirring and extracting the Shilian seeds with 60wt% ethanol aqueous solution, and centrifuging after extraction Separating, collecting the supernatant, concentrating the supernatant, and concentrating it into 60wt% ethanol extract of Echinacea; (4) taking the crushed radish, stirring and extracting the radish with ethyl acetate, and centrifuging after extraction, Collect the supernatant, concentrate the supernatant, and concentrate it into ethyl acetate extract of radish seed; (5) take dand...

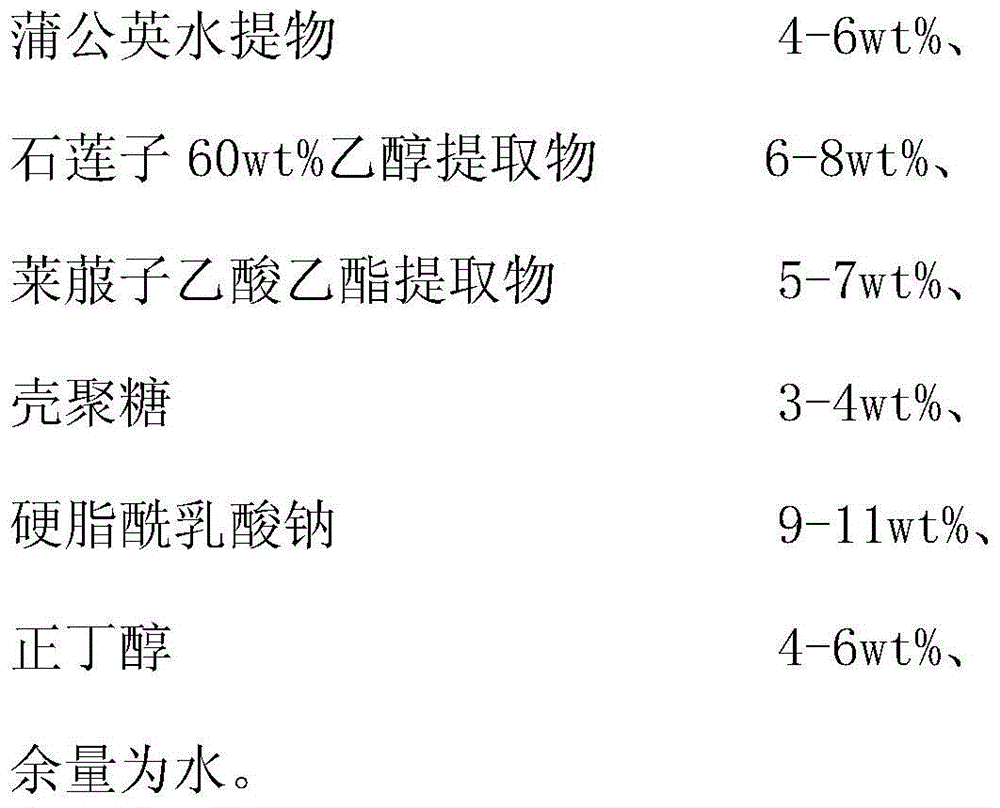

Embodiment 2

[0028] (1) Take dandelion, stone lotus seeds, and radish seeds, and carry out hot air drying respectively at a drying temperature of 80° C. After drying, dandelion, stone lotus seeds, and radish seeds are respectively crushed; (2) Take the crushed dandelions, and stir and extract dandelions with water , centrifugal separation after extraction, collecting the supernatant, concentrating the supernatant, and concentrating the water extract of dandelion; (3) taking the pulverized Shilian seeds, stirring and extracting the Shilian seeds with 60wt% ethanol aqueous solution, and centrifuging after extraction Separating, collecting the supernatant, concentrating the supernatant, and concentrating it into 60wt% ethanol extract of Echinacea; (4) taking the crushed radish, stirring and extracting the radish with ethyl acetate, and centrifuging after extraction, The supernatant is collected, and the supernatant is concentrated, and after concentration, it is an ethyl acetate extract of rad...

Embodiment 3

[0030] (1) Take dandelion, stone lotus seeds, and radish seeds, and carry out hot air drying respectively at a drying temperature of 80° C. After drying, dandelion, stone lotus seeds, and radish seeds are respectively crushed; (2) Take the crushed dandelions, and stir and extract dandelions with water , centrifugal separation after extraction, collecting the supernatant, concentrating the supernatant, and concentrating the water extract of dandelion; (3) taking the pulverized Shilian seeds, stirring and extracting the Shilian seeds with 60wt% ethanol aqueous solution, and centrifuging after extraction Separating, collecting the supernatant, concentrating the supernatant, and concentrating it into 60wt% ethanol extract of Echinacea; (4) taking the crushed radish, stirring and extracting the radish with ethyl acetate, and centrifuging after extraction, The supernatant is collected, and the supernatant is concentrated, and after concentration, it is the ethyl acetate extract of ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com