Device and process method for recovering synthetic ammonia tail gas to produce lng

A technology for synthesizing ammonia and tail gas, which is applied in the field of devices for recycling synthetic ammonia tail gas to produce LNG, which can solve the problems of inability to recycle, low economic benefits, environmental pollution, etc., and achieve the effects of compact structure, reduced energy consumption and operating costs, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

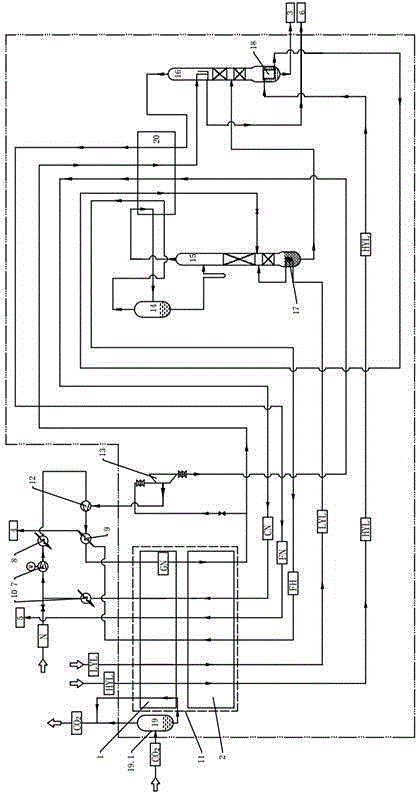

[0024] The present invention will be further described below with reference to the accompanying drawings.

[0025] Such as figure 1As shown, the coke oven raw gas riser sensible heat recovery device provided in this embodiment includes a circulating nitrogen compressor 7, a first cooler 8, a second cooler 9, a third cooler 10, and a Precooling heat exchange device 11, supercharged turbo expander, gas-liquid separator 14, dehydrogenation rectification tower 15 and methane rectification tower 16, said precooling heat exchange device 11 includes carbon dioxide precooler 1 and main Heat exchanger 2; the pre-cooling heat exchange device 11 is provided with a high-pressure tail gas inlet, a low-pressure tail gas inlet, a hydrogen-rich gas outlet, a nitrogen-rich gas outlet, a backflow cycle nitrogen outlet, a high-pressure nitrogen inlet, a high-pressure nitrogen outlet, and a backflow cycle nitrogen inlet , nitrogen-enriched gas inlet, hydrogen-enriched gas inlet, low-pressure tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com