Determination method of taste quality and aroma quality of ripe Pu-erh tea

A technology of Pu'er ripe tea and determination method, which is applied in the preparation of test samples, test food, test beverages, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

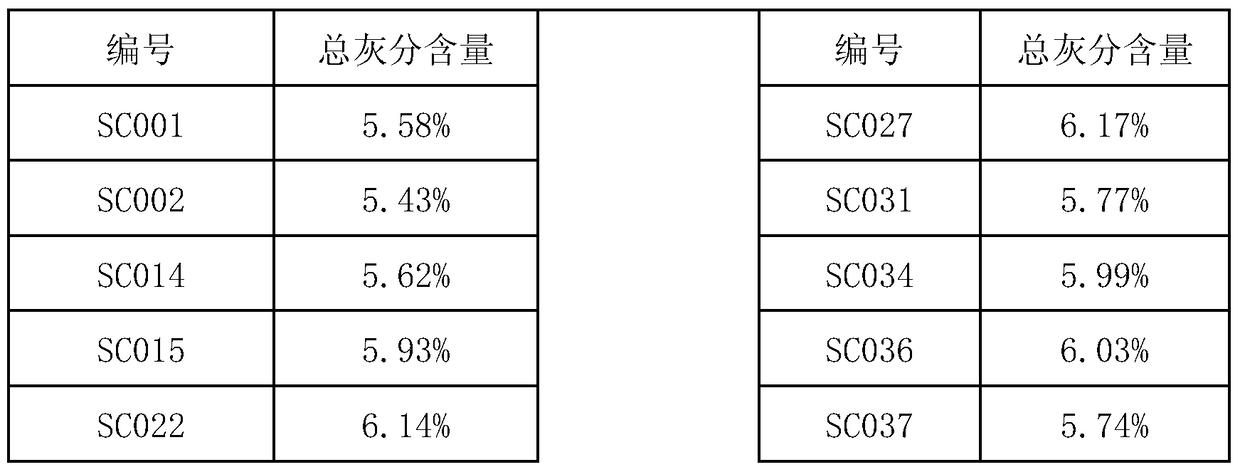

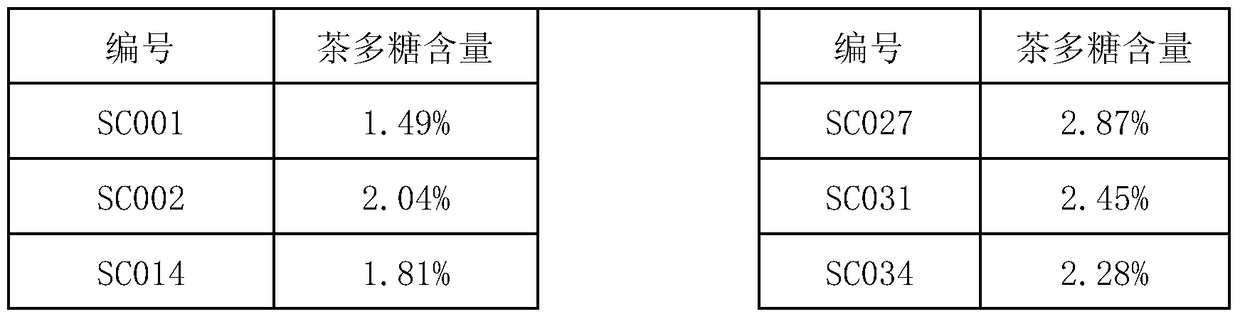

[0046] Aroma sensory evaluation scores of batches of cooked Pu-erh tea samples, as well as water extracts, total ash, tea polysaccharides, tea polyphenols, free amino acids, theaflavins, thearubigins, theabrownins, crude fiber, gallic acid and caffeine The value of content is the data source. According to the correlation between the aroma sensory quality and physical and chemical components of Pu’er ripe tea, select the appropriate data source for the content of physical and chemical components, use SAS software, and adopt the stepwise regression analysis method to establish the regression equation formula of the aroma quality score of Pu’er ripe tea.

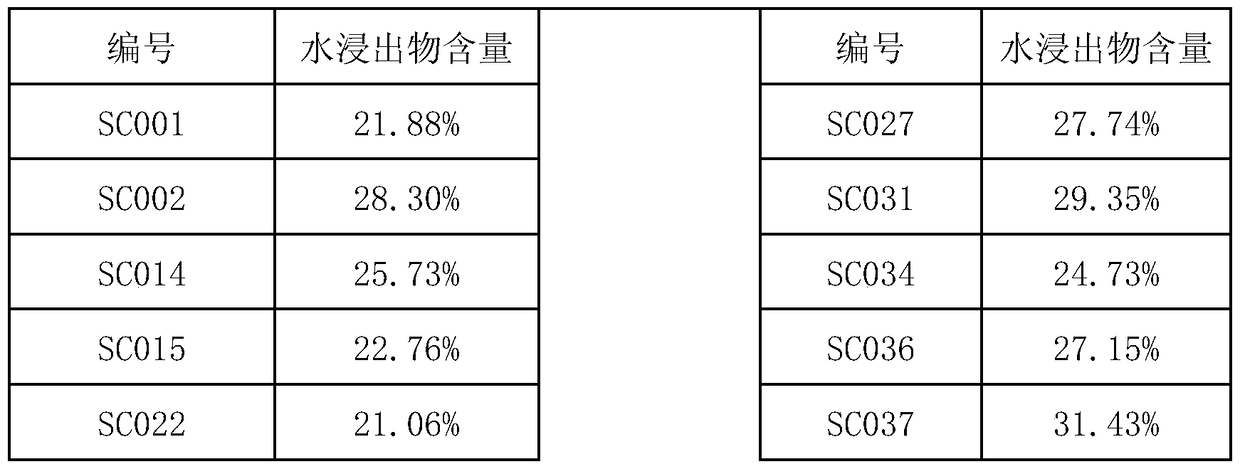

[0047] The content determination method and result of water extract are as follows:

[0048] Weigh the ground sample into the Erlenmeyer flask, add boiling distilled water, immediately move into the boiling water bath, leaching, filter while hot and reduce pressure immediately after the leaching is completed; wash the tea dregs ...

Embodiment 1

[0082] (1) The total score of Pu-erh cooked tea taste quality evaluation (V PFT )=142+133Water extract+3Totalash-3637Polysaccharides+680Polyphenols-1671Amino acid+97623Theaflavins-2222Thearubigins+593Theabrownine+123Crude fiber-103Gallic acid+5281Caffeine+110629Polysaccharides 2 -303 Polyphenols 2 -3463 Theabrownine 2 -26817 Caffeine 2 -382Water extract 2 -3(Polyphenols+Thearubigins / Theabrownine)-Polyphenols / Amino acid-3082Theaflavins / (Theaflavins+Thearubigins+Theabrownine)-202Theabrownine / (Theaflavins+Thearubigins+Theabrownine)+3171(Caffeine×Amino acid)-1963294(Caffeine×Theaflavins)+9662(Polyphenols×Amino acid)-9071(Polyphenols× Polysaccharides)-13826 (Polyphenols×Caffeine) for calculation, V PFT is a percentage system;

[0083] Through the calculation of the above formula, the V of each group of samples is obtained PFT The value is compared with the standard value, see the table below:

[0084] Cooked tea number

[0085] From the above data, it can be seen t...

Embodiment 2

[0087](1) The total score of Pu-erh cooked tea taste quality evaluation (V PFT )=132+133Water extract+3Totalash-3637Polysaccharides+680Polyphenols-1671Amino acid+95243Theaflavins-2222Thearubigins+593Theabrownine+123Crude fiber-103Gallic acid+5281Caffeine+110089Polysaccharides 2 -303 Polyphenols 2 -3463 Theabrownine 2 -25714 Caffeine 2 -382Water extract 2 -3(Polyphenols+Thearubigins / Theabrownine)-Polyphenols / Amino acid-3082Theaflavins / (Theaflavins+Thearubigins+Theabrownine)-202Theabrownine / (Theaflavins+Thearubigins+Theabrownine)+3171(Caffeine×Amino acid)-1955421(Caffeine×Theaflavins)+9662(Polyphenols×Amino acid)-9071(Polyphenols× Polysaccharides)-13062 (Polyphenols×Caffeine) for calculation, V PFT is a percentage system;

[0088] Through the calculation of the above formula, the V of each group of samples is obtained PFT The value is compared with the standard value, see the table below:

[0089] Cooked tea number

[0090] It can be seen from the above data tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com