Backside illuminated CMOS sensor and preparation method thereof

A CMOS sensor and back-illuminated technology, which is applied in the field of back-illuminated CMOS sensors and the preparation of the sensor, can solve the problems that the quantum conversion efficiency of the sensor needs to be improved, and achieve the effect of improving the quantum conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Figure 6 It is a structural schematic diagram of a back-illuminated CMOS sensor in an embodiment of the present invention; as Figure 6 As shown, a back-illuminated CMOS sensor (BSI CMOS sensor), the sensor includes a wafer 1 with several photodiodes 2 and a dielectric layer 3 arranged on the front of the wafer 1, and the dielectric layer 3 is close to the wafer 1 A groove 4 is provided at the position and the groove 4 is located below the photodiode 2, and a light-reflecting material is arranged in the groove 4, wherein the groove 4 is a rectangular structure, and its width is greater than that of the photodiode 2, and the dielectric layer 3 is also provided with a There are through holes 5 and metal interconnection lines 6, one end of the through hole 5 is connected to the electrode of the wafer 1, and the other end is connected to the metal interconnection line 6, metal is provided in the through hole 5, and a wafer substrate 11 is located on the wafer 1, the optic...

Embodiment 2

[0043] Figure 1~5 It is a schematic flow chart of the method for preparing a back-illuminated CMOS sensor in an embodiment of the present invention, Figure 6 is a schematic structural diagram of a back-illuminated CMOS sensor in an embodiment of the present invention, such as Figure 1~6 Shown:

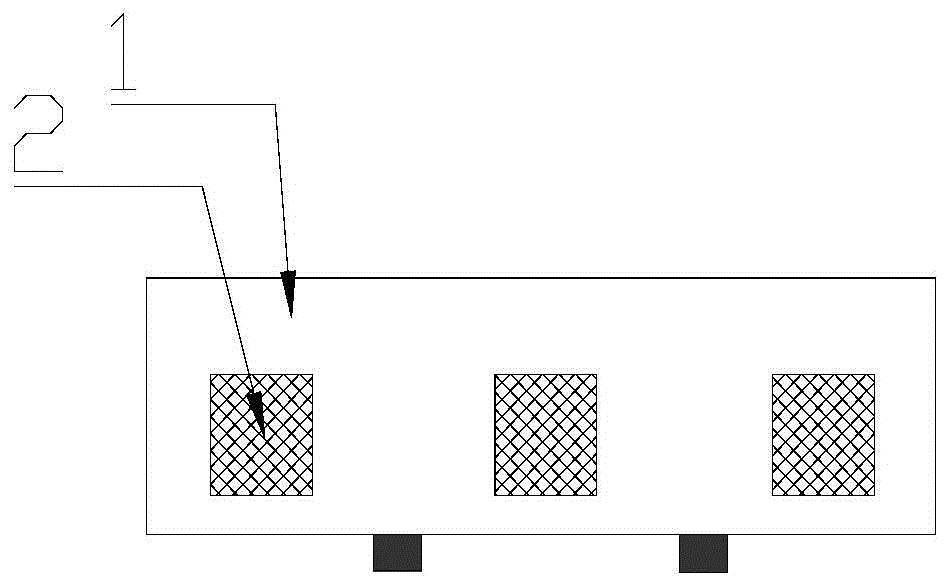

[0044] First provide a wafer 1 with several photodiodes 2, such as figure 1 the structure shown;

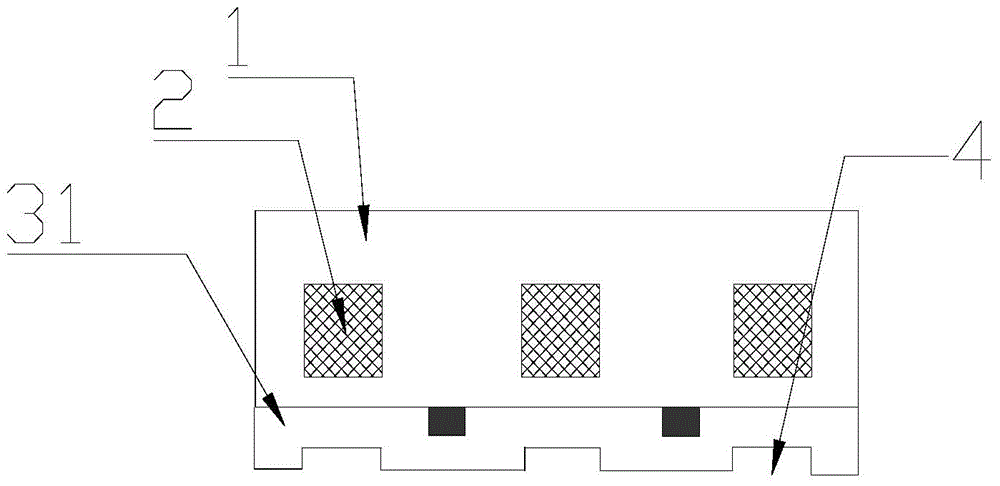

[0045] Next, deposit a first dielectric layer 31 on the front of the wafer 1, and etch the first dielectric layer 31 below the photodiode 2 to form a trench 4, which can be dry-etched or wet-etched, and the trench 4 has a rectangular structure, and width is greater than the width of the photodiode, as figure 2 the structure shown;

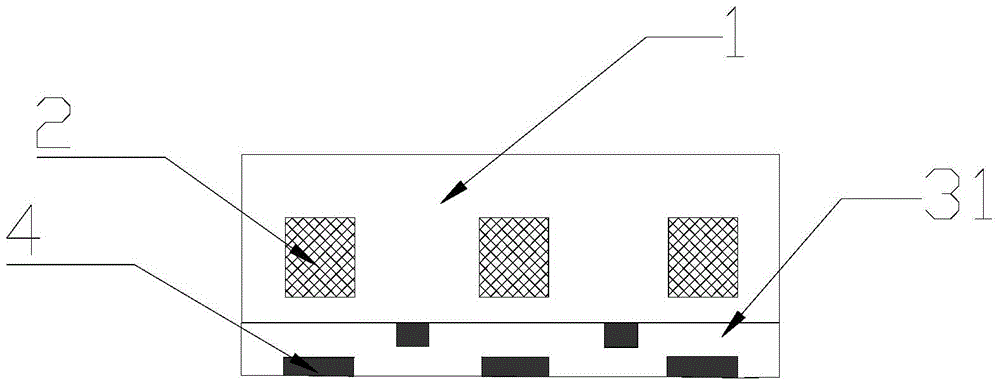

[0046]Then, deposit a reflective substance such as aluminum or tungsten on the groove 4, and perform polishing, which can be polished by chemical mechanical polishing (CMP), such as image 3 the structure shown;

[0047] Then, deposit the second die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com