2-micron thulium-doped solid laser pumped in 1.6-micron erbium-doped laser cavity

A solid-state laser and solid-state laser technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as limiting laser power scaling and amplification capabilities, reducing laser efficiency and beam quality, increasing thermal effects of laser materials, etc., to achieve Guarantee the laser power calibration amplification ability, reduce the thermal effect, improve the effect of laser efficiency and beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Taking Er:YAG and Tm:YAG crystals as examples to further illustrate the implementation process of this scheme.

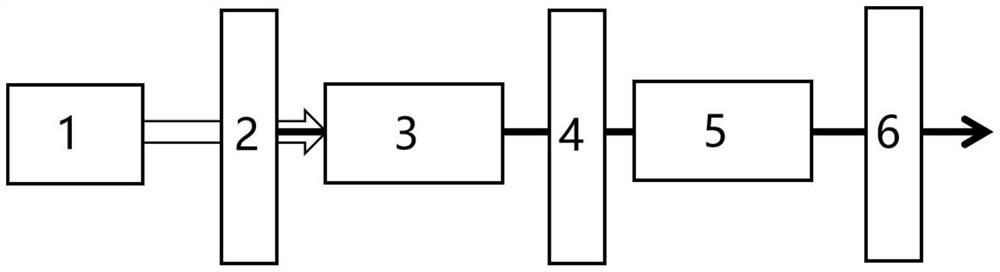

[0034] According to the absorption spectrum of Er:YAG, 1532nm erbium-doped fiber laser is selected as the pumping source of 1.5μm to pump Er:YAG crystal to generate 1617nm laser. The Er:YAG crystal is placed between the input mirror 2 and the intermediate mirror 4 , and the Tm:YAG crystal is placed between the intermediate mirror 4 and the output mirror 6 . The coating of the input mirror 2 has high transmittance (T>98%) for 1532nm and high reflectivity (R>99.8%) for 1617nm laser. The coating of the intermediate mirror 4 has high transmittance (T>98%) for 1617nm and high reflectivity (R>99.8%) for 2015nm laser. The coating of the output mirror 6 has high reflectivity (T>99.8%) for 1617nm and high partial reflectivity (eg R=95%) for 2015nm laser. From the coating conditions of the above cavity mirrors, it can be seen that the input mirror 2 and the output mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com