An epitaxy method to improve current spreading of gan-based LED chips

A LED chip and current expansion technology, which is applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as voltage increase and chip leakage increase, and achieve the effects of improving uniformity, reducing local junction temperature, and overcoming brightness aggregation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

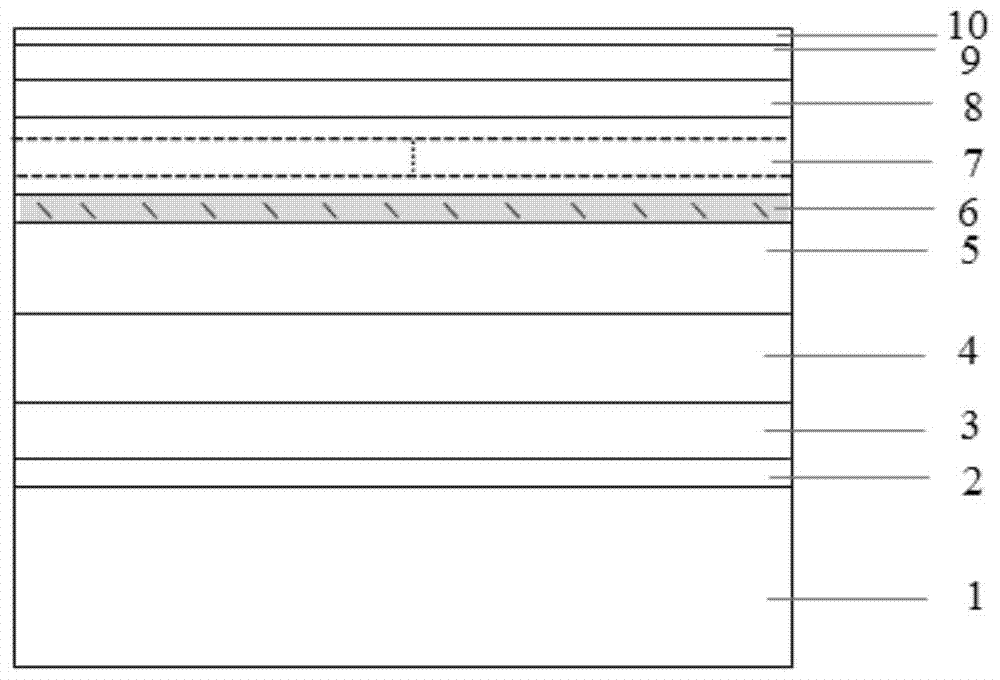

[0033] An epitaxial method for improving the current expansion of a GaN-based LED chip, the method comprising the following specific steps:

[0034] Step 1, annealing the sapphire substrate 1 in a hydrogen atmosphere, cleaning the surface of the sapphire substrate 1, controlling the temperature at 1040° C., and then performing nitriding treatment for 5 minutes;

[0035] Step 2: Lower the temperature to 500°C, grow a 20nm-thick low-temperature GaN nucleation layer 2, control the growth pressure at 450Torr, set the V / III molar ratio at 60, and use TMGa as the Ga source;

[0036] Step 3: After the growth of the low-temperature GaN nucleation layer 2 is completed, stop feeding TMGa, perform in-situ annealing treatment, the annealing temperature is 1020°C, and the annealing time is 5 minutes; after annealing, adjust the temperature to 980°C, and the epitaxial growth thickness is 600nm High-temperature GaN buffer layer 3, the growth pressure is 450 Torr, the V / III molar ratio is 200...

Embodiment 2

[0048] An epitaxial method for improving the current expansion of a GaN-based LED chip, the method comprising the following specific steps:

[0049] Step 1, annealing the sapphire substrate 1 in a hydrogen atmosphere, cleaning the surface of the sapphire substrate 1, controlling the temperature at 1080°C, and then performing nitriding treatment for 10 minutes;

[0050] Step 2: Lower the temperature to 550°C, grow a 40nm-thick low-temperature GaN nucleation layer 2, control the growth pressure at 550Torr, keep the V / III molar ratio at 120, and use TMGa as the Ga source;

[0051] Step 3: After the growth of the low-temperature GaN nucleation layer 2 is completed, stop feeding TMGa, perform in-situ annealing treatment, the annealing temperature is 1050°C, and the annealing time is 10 minutes; after the annealing, adjust the temperature to 1050°C, and the epitaxial growth thickness is 800nm High-temperature GaN buffer layer 3, the growth pressure is 550 Torr, the V / III molar ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com