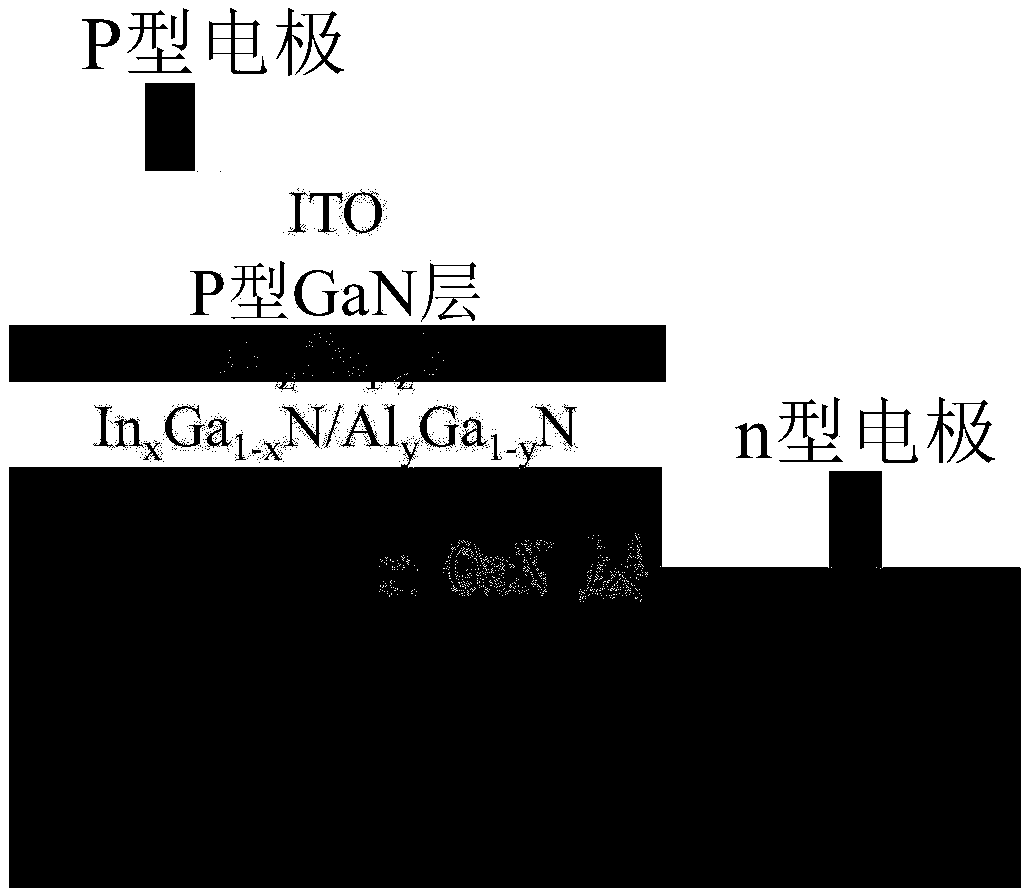

GaN high-efficiency light-emitting diode based on physical polishing roughening ITO layer and manufacturing method

A light-emitting diode, grinding and roughening technology, applied in the field of microelectronics, can solve the problems of long period of light-emitting diodes, high cost, complex process, etc., and achieve the effects of improving light extraction efficiency, reducing costs, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, preparing a light emitting diode with a light emission wavelength of 370nm.

[0038] In step one, the substrate is pretreated.

[0039] After the sapphire substrate was cleaned, it was placed in the metal organic chemical vapor deposition MOCVD reaction chamber, and the vacuum degree of the reaction chamber was reduced to 2×10 -2 Torr: Introduce the mixed gas of hydrogen and ammonia into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 20 Torr, the substrate is heated to a temperature of 750°C and kept for 10 minutes to complete the pretreatment of the substrate.

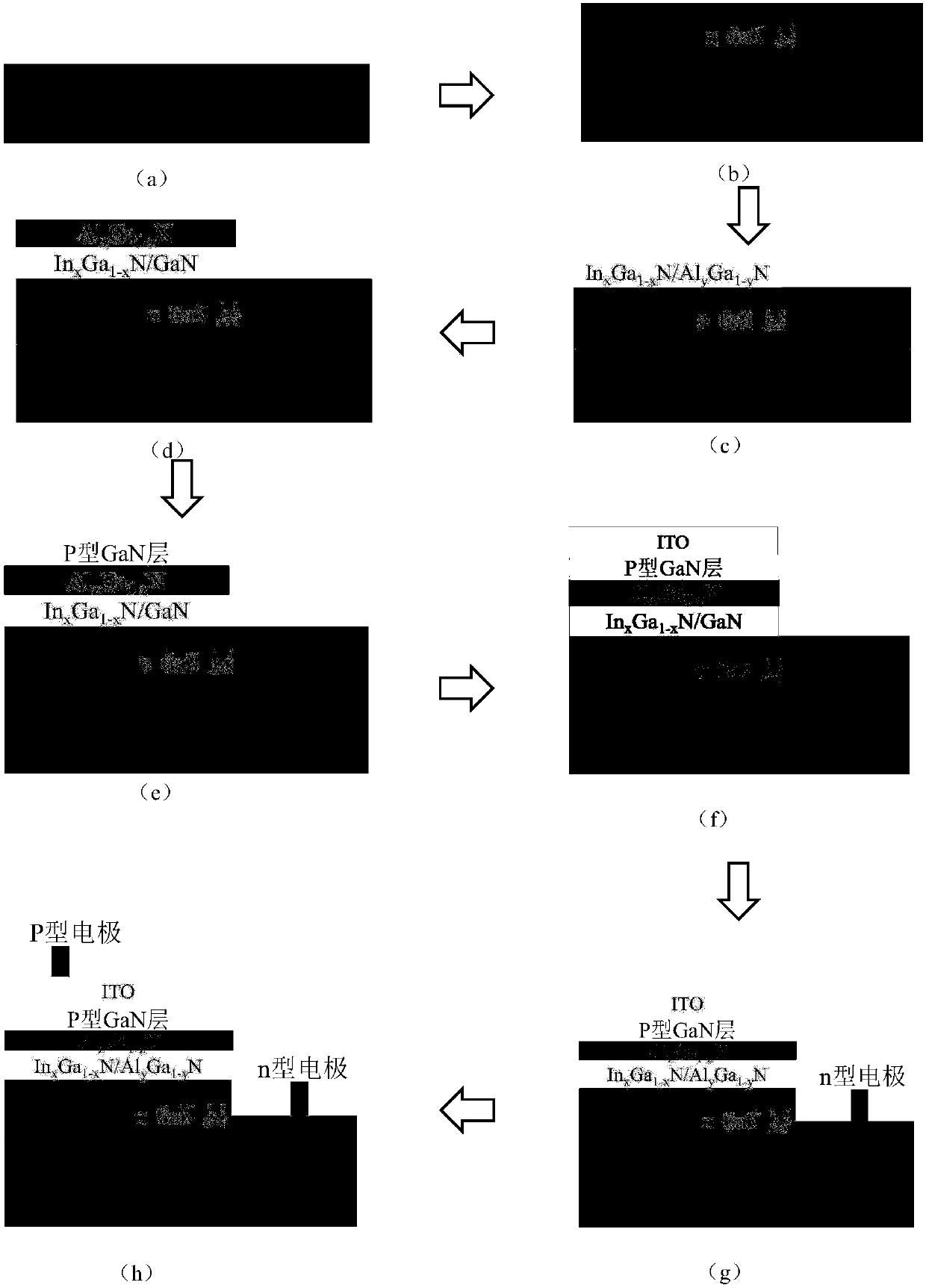

[0040] Step 2, using the MOCVD process to grow a high-temperature AlN layer, such as figure 2 (a).

[0041] Adjust the temperature of the reaction chamber to 950°C, feed ammonia gas with a flow rate of 2500 sccm and an aluminum source with a flow rate of 40 sccm at the same time, and grow a high-temperature AlN substrate with a thickness of 50 n...

Embodiment 2

[0061] Example 2, preparing a light emitting diode with a light emitting wavelength of 410 nm.

[0062] Step 1, pretreating the substrate.

[0063] After the sapphire substrate was cleaned, it was placed in the metal organic chemical vapor deposition MOCVD reaction chamber, and the vacuum degree of the reaction chamber was reduced to 2×10 -2 Torr: Introduce the mixed gas of hydrogen and ammonia into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 780 Torr, the substrate is heated to a temperature of 1000°C and kept for 5 minutes to complete the pretreatment of the substrate

[0064] Step 2, using the MOCVD process to grow a high-temperature AlN layer, such as figure 2 (a).

[0065] The temperature of the reaction chamber was adjusted to 900°C, and the ammonia gas with a flow rate of 2000 sccm and the aluminum source with a flow rate of 20 sccm were fed at the same time, and the pressure was maintained at 60 Torr to grow ...

Embodiment 3

[0084] Example 3, preparing a light emitting diode with a light emitting wavelength of 540nm.

[0085] Step A, pretreating the substrate.

[0086] After the c-plane sapphire substrate was cleaned, it was placed in the metal organic chemical vapor deposition MOCVD reaction chamber, and the vacuum degree of the reaction chamber was reduced to 2×10 -2 Torr: Introduce the mixed gas of hydrogen and ammonia into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 120 Torr, the substrate is heated to a temperature of 850°C and kept for 8 minutes to complete the pretreatment of the substrate.

[0087] In step B, a high-temperature AlN layer is grown by MOCVD process.

[0088] Adjust the temperature of the reaction chamber to 1000°C, feed ammonia gas with a flow rate of 3000 sccm and an aluminum source with a flow rate of 30 sccm at the same time, and grow a high-temperature AlN substrate with a thickness of 110 nm on the nitrided subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com