Technology for supertex protein prepared from ethanol leached soy protein concentrate

A technology for soybean protein concentrate and drawing protein, which is applied in the processing field of texturized drawing protein, and can solve the problems of poor texturing effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

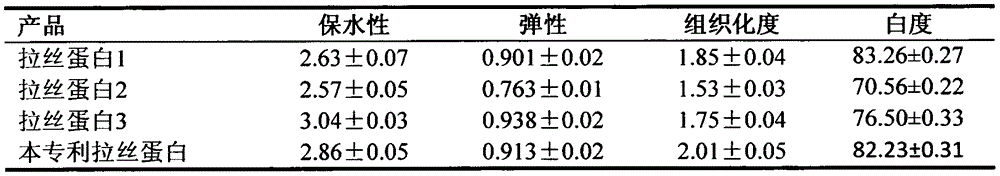

Examples

Embodiment 1

[0040] (1) First, 1 kg of alcohol-soluble soybean protein concentrate was prepared into a 25% suspension, and placed in an ultrasonic pulverizer with an ultrasonic power of 600 W for 15 minutes. The protein aqueous solution after ultrasonic treatment is subjected to high-pressure homogenization treatment, the pressure is 20MPa, and the time is 15min;

[0041] (2) Mix the pretreated soybean protein concentrate solution with other auxiliary materials using a mixer. Calculated according to the dry weight of the material, the soybean protein concentrate, gluten powder, starch, and konjac powder are mixed, and the proportions of each component are respectively The proportions are: soybean protein concentrate: 65%, gluten powder: 15%, starch: 15%, konjac flour 0.1%, salt 1.5%, baking soda content 1%, lecithin 0.05%, and the final water content of the control material is 30% %

[0042] (3) After adjusting the water content, use sodium bicarbonate to adjust the pH of the mixed materi...

Embodiment 2

[0045] (1) Firstly, 5 kg of alcohol-soluble soybean protein concentrate was prepared into a 25% suspension, and placed in an ultrasonic pulverizer with an ultrasonic power of 600 W for 20 minutes. The protein aqueous solution after ultrasonic treatment is subjected to high-pressure homogenization treatment, the pressure is 20MPa, and the time is 10min;

[0046] (2) Mix the pretreated soybean protein concentrate solution with other auxiliary materials using a mixer. Calculated according to the dry weight of the material, the soybean protein concentrate, gluten powder, starch, and konjac powder are mixed, and the proportions of each component are respectively The proportions are: soybean protein concentrate: 60%, gluten powder: 20%, starch: 15%, konjac flour 0.1%, salt 1.5%, baking soda content 1%, lecithin 0.1%, and the final water content of the control material is 30% %

[0047] (3) After adjusting the water content, use sodium bicarbonate to adjust the pH of the mixed mater...

Embodiment 3

[0050] (1) First, 10 kg of alcohol-soluble soybean protein concentrate was prepared into a 25% suspension, and placed in an ultrasonic pulverizer with an ultrasonic power of 700 W for 20 minutes. The protein aqueous solution after ultrasonic treatment is subjected to high-pressure homogenization treatment, the pressure is 20MPa, and the time is 15min;

[0051] (2) The concentrated soybean protein solution after pretreatment is mixed with other auxiliary materials by a mixer. Calculated according to the dry weight of the material, the concentrated soybean protein, gluten powder, starch, and konjac powder are mixed. The proportions are: soybean protein concentrate: 65%, gluten powder: 15%, starch: 15%, konjac flour 0.1%, salt 1.5%, baking soda content 1%, lecithin 0.05%, and the final water content of the control material is 30%

[0052] (3) After adjusting the water content, use sodium bicarbonate to adjust the pH of the mixed material, so that the pH of the mixed raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com