Method for refining xylose hydrolysate

A technology for xylose hydrolyzate and residual liquid, applied in the field of functional sugar, can solve problems such as large water consumption, clogging of electrode membrane stacks, breakage and other problems, saving acid and alkali consumption and water consumption, low maintenance cost, desalination good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

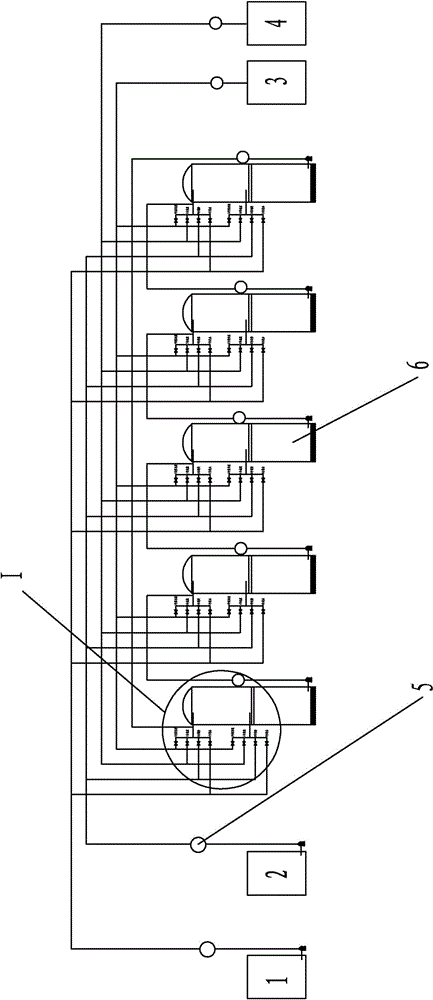

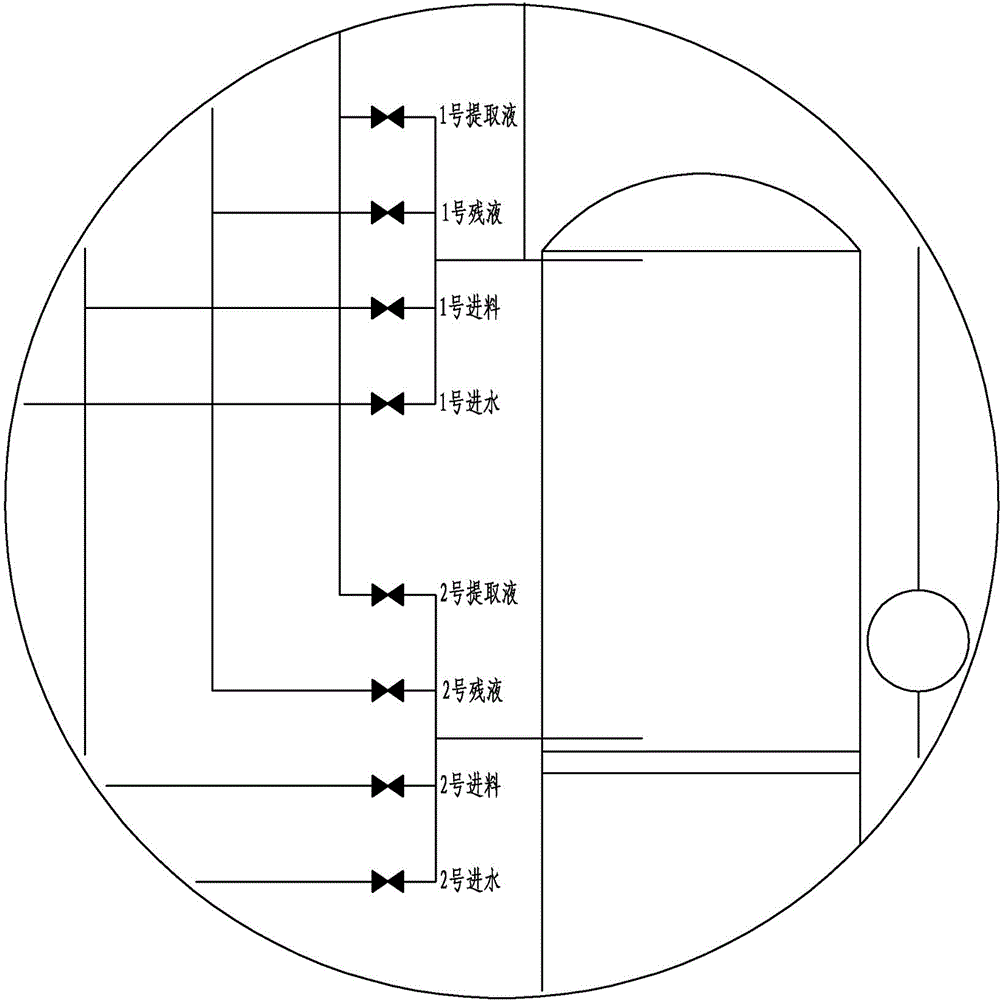

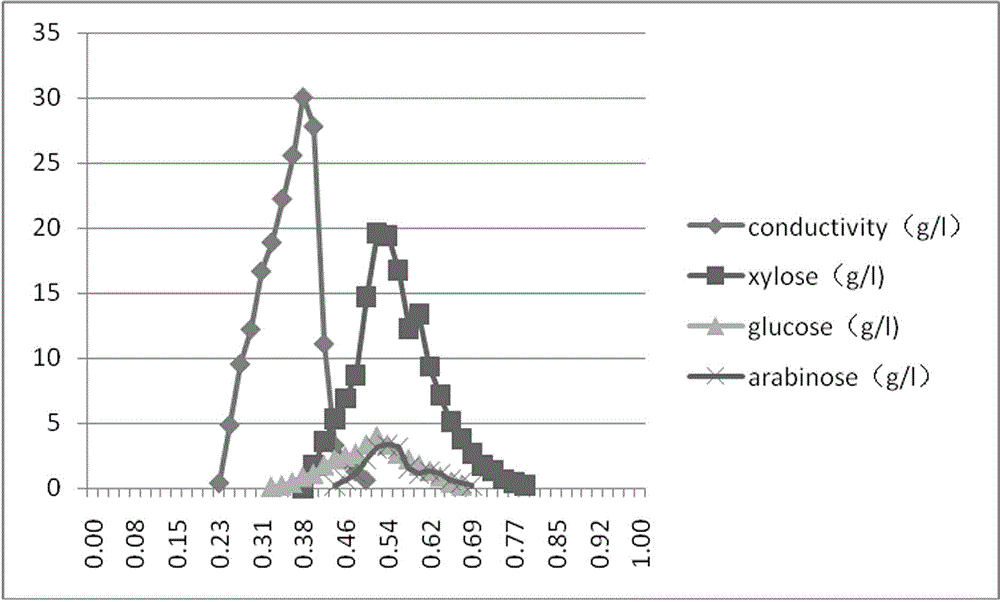

[0029] Using 10 independent separation chambers in series (such as figure 1 shown), such as figure 1 As shown, from left to right are separation chambers 1-10, and each separation chamber has independent pipelines and valves for feeding, water inlet, extracting liquid, and raffinate (partial enlarged view of separation chambers 1 and 2 See figure 2 , the pipes and valves of other separation chambers are basically the same as separation chambers 1 and 2). In the normal production process, the material is fed first in the whole system, and the separation curve is formed through the circulation pump, and the circulation flow in the whole circulation system is 39.1m 3 / h water inflow is 7m 3 / h, the feed rate is 4m 3 / h, refraction (equivalent to the concentration of dry matter) 45%; the output of the extract (the enriched sugar-containing part in the solution) is 3.75m 3 / h, the refraction is 26%; the amount of the raffinate (the part of the solution enriched with impurity ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap