Electroslag cast combined double-metal double-surface hammer and manufacturing method thereof

An electroslag casting and bimetal technology, applied in grain processing and other directions, can solve the problems of high labor intensity of workers, large consumption of hammer heads, and high use costs, reducing the addition of precious metals, high production efficiency, and reduced use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

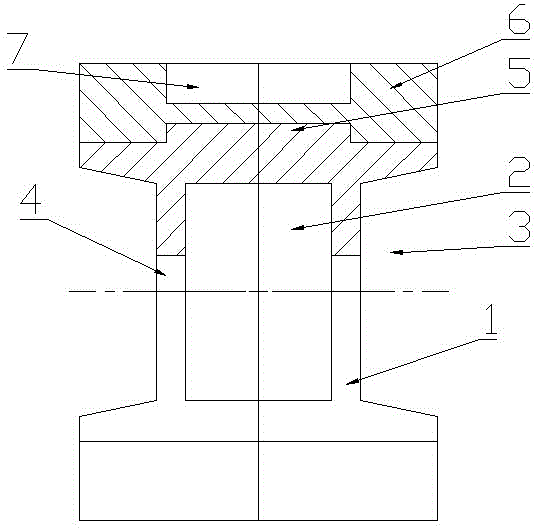

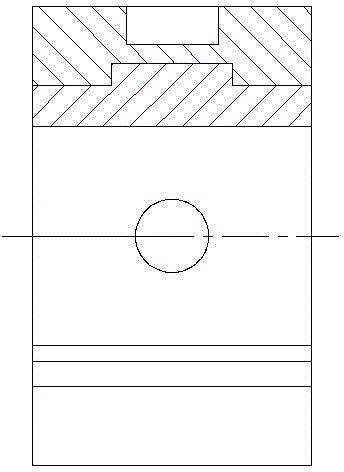

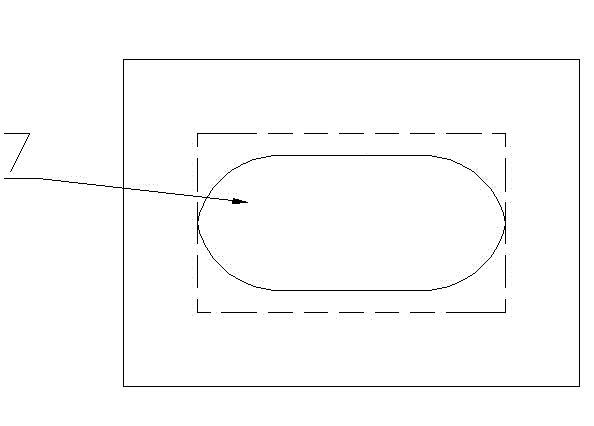

[0027] The electroslag casting combined bimetal double-sided hammer head includes a hammer body 1 with a rectangular hole 2 in the middle, recesses 3 are provided on both sides of the hammer body 1 corresponding to the rectangular hole 2, and the hammer body 1 corresponds to the The recess 3 is provided with a pin hole 4 communicating with the rectangular hole 2 for connecting the combined hammer handle. The distance between the upper and lower end surfaces of the rectangular hole 2 and the corresponding upper and lower end surfaces of the hammer body 1 is 5 mm. The middle part of the upper and lower end surfaces of the body 1 is provided with a boss 5 with a height of 10 mm. The cross section of the boss 5 is rectangular, and the distance between the edge of the boss 5 and the edge of the corresponding upper and lower end surfaces of the hammer body 1 is 15mm, the upper and lower end surfaces of the hammer body 1 are provided with a high-chromium cast iron wear-resistant layer...

Embodiment 2

[0036] The electroslag casting combined bimetal double-sided hammer head includes a hammer body 1 with a rectangular hole 2 in the middle, recesses 3 are provided on both sides of the hammer body 1 corresponding to the rectangular hole 2, and the hammer body 1 corresponds to the The recess 3 is provided with a pin hole 4 communicating with the rectangular hole 2 for connecting the combined hammer handle. The distance between the upper and lower end surfaces of the rectangular hole 2 and the corresponding upper and lower end surfaces of the hammer body 1 is 10 mm. The middle part of the upper and lower end faces of the body 1 is provided with a boss 5 with a height of 20 mm. The cross section of the boss 5 is rectangular, and the distance between the edge of the boss 5 and the edge of the upper and lower end faces of the corresponding hammer body 1 is 30mm, the upper and lower end surfaces of the hammer body 1 are provided with a high-chromium cast iron wear-resistant layer 6 fo...

Embodiment 3

[0045]The electroslag casting combined bimetal double-sided hammer head includes a hammer body 1 with a rectangular hole 2 in the middle, recesses 3 are provided on both sides of the hammer body 1 corresponding to the rectangular hole 2, and the hammer body 1 corresponds to the The recess 3 is provided with a pin hole 4 communicating with the rectangular hole 2 for connecting the combined hammer handle. The distance between the upper and lower end surfaces of the rectangular hole 2 and the corresponding upper and lower end surfaces of the hammer body 1 is 8 mm. The middle part of the upper and lower end faces of the body 1 is provided with a boss 5 with a height of 15 mm. The cross section of the boss 5 is rectangular, and the distance between the edge of the boss 5 and the edge of the upper and lower end faces of the corresponding hammer body 1 is 25mm, the upper and lower end surfaces of the hammer body 1 are provided with a high-chromium cast iron wear-resistant layer 6 form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com