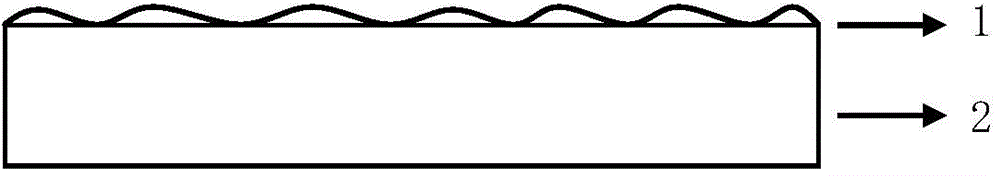

Anti-dazzle glass as well as preparation method and application thereof

An anti-glare and glass technology is applied in the field of anti-glare glass and its preparation, which can solve the problems of high equipment cost and high technical requirements, and achieve the effects of simplifying production processes, increasing light transmittance and bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Take a piece of finished flat display glass panel after cleaning, with a thickness of 0.5, 0.7, and 0.9mm, respectively, and send them into a chemical etching machine.

[0024] 2. Use high-pressure spray to evenly spray the chemical liquid on the glass treatment surface, and the spray pressure is 1.5kg / cm 2 , The residence time of the glass substrate is 10s.

[0025] 3. Take out the glass and rinse it with running water, then wipe it clean with a dust-free cloth.

Embodiment 2

[0027] 1. Take a piece of cleaned capacitive screen mobile phone cover glass with a thickness of 0.5, 0.7, and 0.9 mm and send them to a chemical etching machine.

[0028] 2. Use high-pressure spraying method to evenly spray the chemical liquid on the glass treatment surface, and the spraying pressure is 2kg / cm 2 , The residence time of the glass substrate is 2s.

[0029] 3. Take out the glass and rinse it with running water, then wipe it clean with a dust-free cloth.

Embodiment 3

[0031] 1. Take a finished piece of cleaned projected capacitive touch screen with a thickness of 0.5, 0.7, and 0.9 mm and send it to a chemical etching machine.

[0032] 2. Use high-pressure spraying method to evenly spray the chemical liquid on the glass treatment surface, and the spraying pressure is 1kg / cm 2 , The residence time of the glass substrate is 15s.

[0033] 3. Take out the glass and rinse it with running water, then wipe it clean with a dust-free cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com