Magnesium-iron brick preparation raw material capable of increasing high temperature bending strength of magnesium-iron brick and magnesium-iron brick preparation process

A technology of flexural strength and magnesia-iron bricks is applied in the field of preparing raw materials for magnesia-iron bricks, which can solve the problems of unsuitability of magnesia-alumina spinel bricks, damage to the brick body structure, unfavorable hanging kiln skin, etc. The effect of low rate and few kinds of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

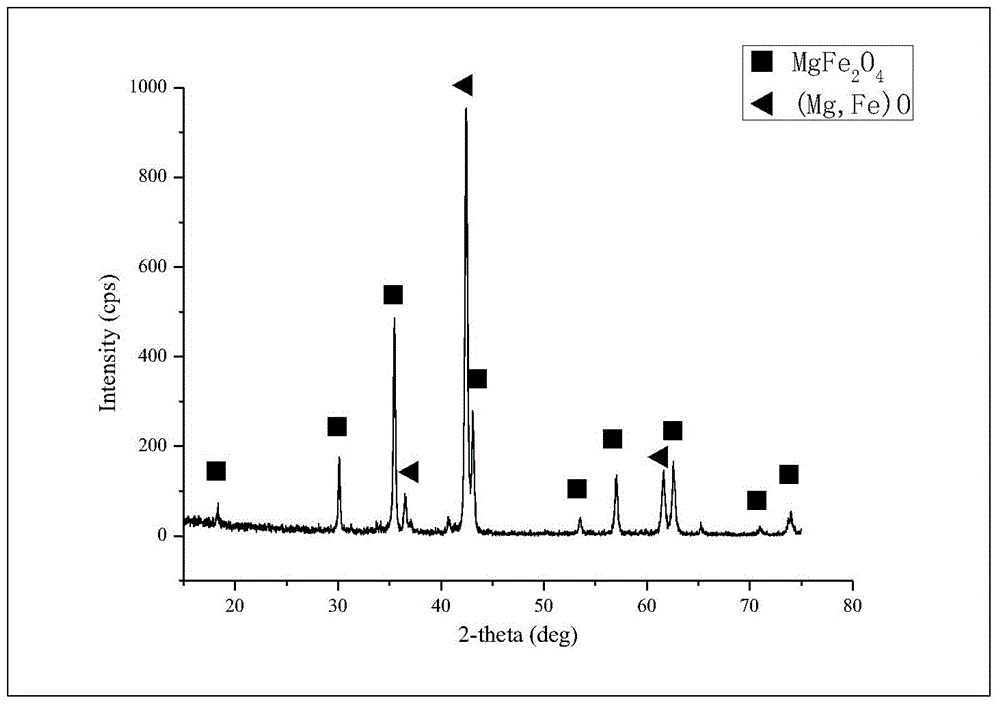

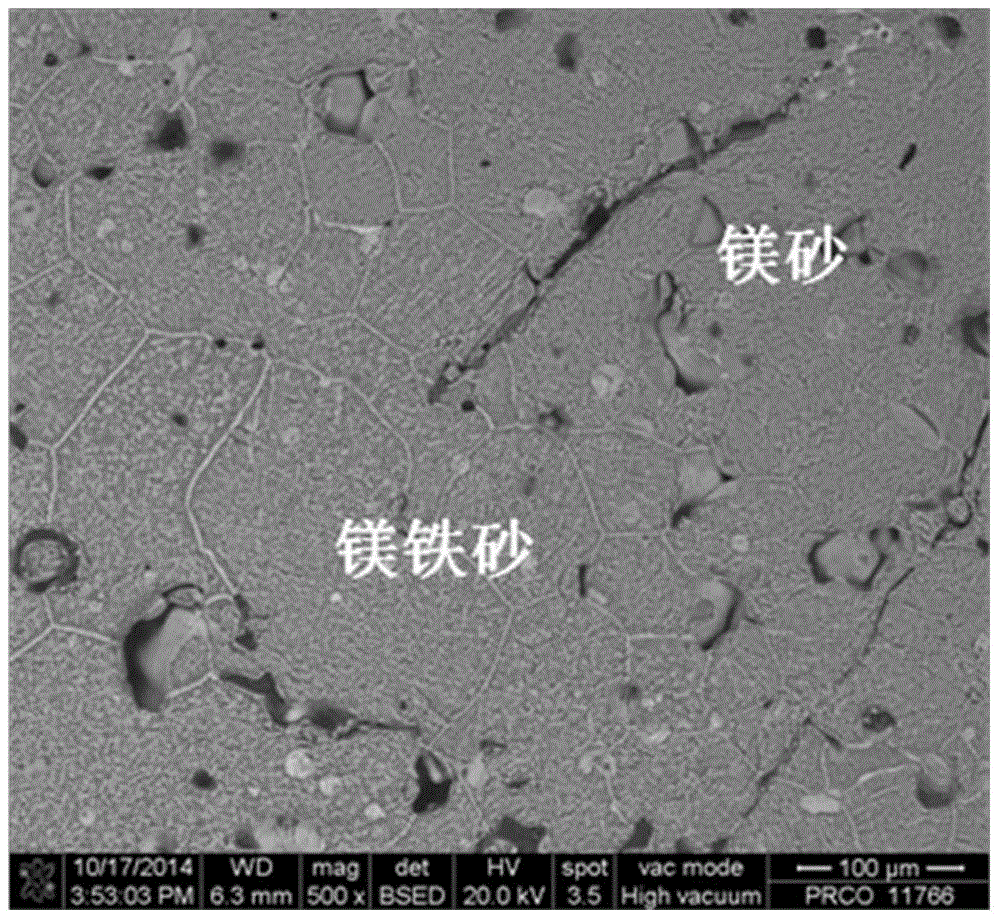

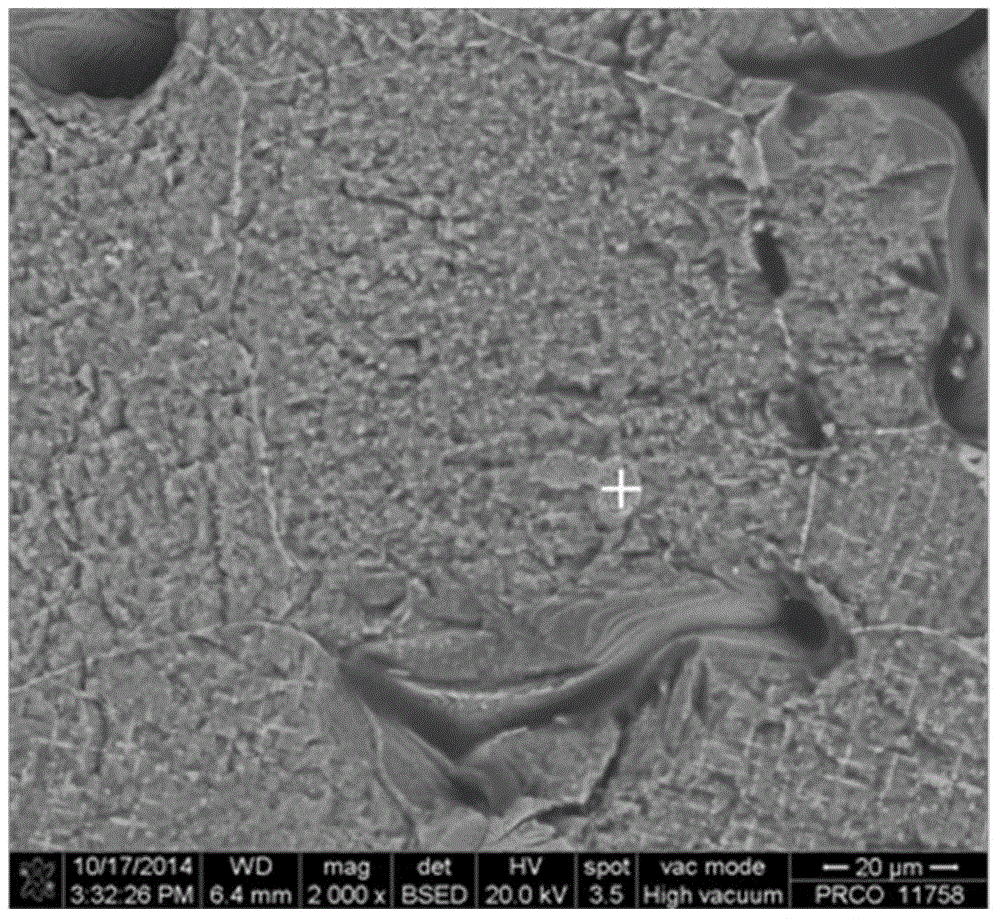

Method used

Image

Examples

Embodiment 1

[0034] A magnesia-iron brick preparation raw material capable of improving the high-temperature flexural strength of magnesia-iron bricks. The magnesia-iron brick preparation raw material consists of the following components:

[0035] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 5 mm and greater than 3 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 18 wt %;

[0036] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 3 mm and greater than 1 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 21 wt %;

[0037] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 1 mm and greater than 0.088 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 20 wt%;

[0038] The mass percentage of MgO ...

Embodiment 2

[0045] A magnesia-iron brick preparation raw material capable of improving the high-temperature flexural strength of magnesia-iron bricks. The magnesia-iron brick preparation raw material consists of the following components:

[0046] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 5 mm and greater than 3 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 15 wt %;

[0047] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 3 mm and greater than 1 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 32 wt %;

[0048] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 1 mm and greater than 0.088 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 13 wt %;

[0049] The mass percentage of MgO...

Embodiment 3

[0056] A magnesia-iron brick preparation raw material capable of improving the high-temperature flexural strength of magnesia-iron bricks. The magnesia-iron brick preparation raw material consists of the following components:

[0057] High-purity magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 5 mm and greater than 3 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 15 wt %;

[0058] High-purity magnesia with a mass percentage of MgO of 97% by weight and a particle size of less than or equal to 3mm and greater than 1mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 30% by weight;

[0059] Fused magnesia with a mass percentage of MgO of 97 wt% and a particle size of less than or equal to 1 mm and greater than 0.088 mm, whose mass percentage in the raw materials for the preparation of magnesia-iron bricks is 14 wt%;

[0060] The mass percentage of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com