Azo type disperse dyes suitable for dyeing in acid-alkaline bath, preparation and application

A disperse dye, alkaline technology, applied in azo dyes, monoazo dyes, dyeing methods, etc., can solve the problems of poor dye depth, low dyeing rate, slow dyeing speed, etc., and achieve sublimation fastness. Good, high dye uptake, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

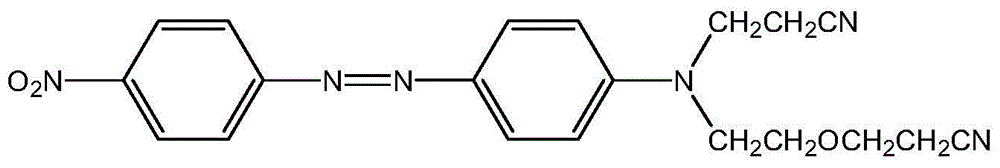

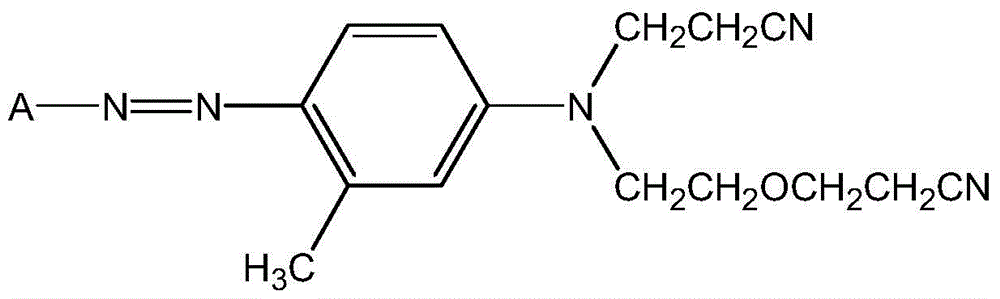

Problems solved by technology

Method used

Image

Examples

Embodiment 1

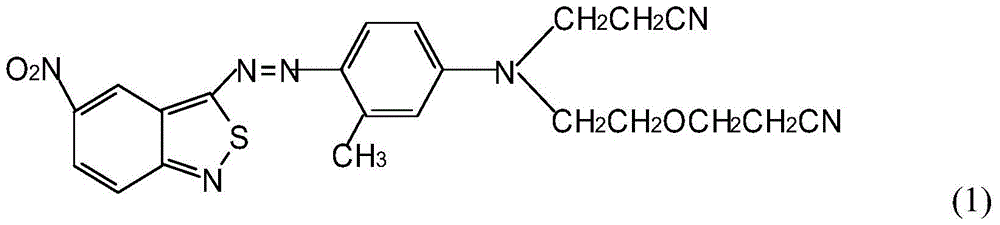

[0022] First add 13.3 grams (100%) of nitrosyl sulfuric acid (0.105 mole), jacket cooling, slowly add 19.5 grams (100%) 3-amino-5-nitro-2,1-benzisothiazole (0.1 mol), when adding, the temperature was less than 5°C, and the temperature was kept at 0-5°C for 4 hours to obtain diazonium liquid; Aniline (0.105 mol) was dissolved in 20 grams of 98% sulfuric acid and 250 grams of ice water, added crushed ice to cool below 0°C, then added dropwise the diazo solution to the coupling components under stirring at 0-5°C, and reacted to The diazo component disappears as the end point, the temperature is raised to 70°C, filtered, the filter cake is washed with water until neutral, and dried to obtain 42.2 grams of disperse dye. Yield 88.8%.

Embodiment 2~6

[0024] Adjust the molar ratio of the coupling component: diazo component to 1.08:1.0; 1.02:1.0 and the filtration temperature of the coupling material to 50°C; 60°C; 80°C. The results are summarized in Table 1 below:

[0025] Table 1

[0026]

[0027]

[0028] A series of physical and chemical performance tests were carried out in the above-mentioned embodiments 1-6, and the specific test results are shown in Table 2:

[0029] Table 2

[0030] Example

Melting pointm.p(℃)

R f value

Maximum absorption wavelength max(nm)

1

164.7-165.7

0.27

600

Royal blue

2

163.5-164.4

0.27

600

Royal blue

3

163.5-164.5

0.27

600

Royal blue

4

163.8-164.7

0.27

600

Royal blue

5

163.8-164.7

0.27

600

Royal blue

6

163.0-163.9

0.27

600

Royal blue

[0031] Dyeing application

[0032] The dye monomer that embodiment 1-6 makes is respectively with met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com