A cement-based composite self-insulating high-strength energy-saving block

A cement-based and block-based technology, which is applied in thermal insulation, building components, sustainable waste treatment, etc., can solve the problems of insufficient thermal insulation performance of thermal insulation bricks, can not reduce the fire performance of materials, service life and construction convenience performance and indicators, etc., to achieve Good fireproof performance, not easy to hollow, improve the effect of heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Raw materials were weighed according to the following proportions by weight: 250kg of ordinary portland cement, 700kg of slag, 300kg of fly ash, 80kg of high-strength ceramsite, 20kg of vitrified microbeads, and 0.1kg of multifunctional admixture. Among them, the fly ash is Class III fly ash; the particle size of slag is 0.4-0.6mm; the particle size of high-strength ceramsite is 8-15mm; the particle size of vitrified microbeads is 0.5-1.5mm; 2 、Na 2 SiO3, K 2 SO 4 It is made by mixing according to the weight ratio of 0.1:0.9:1:0.4.

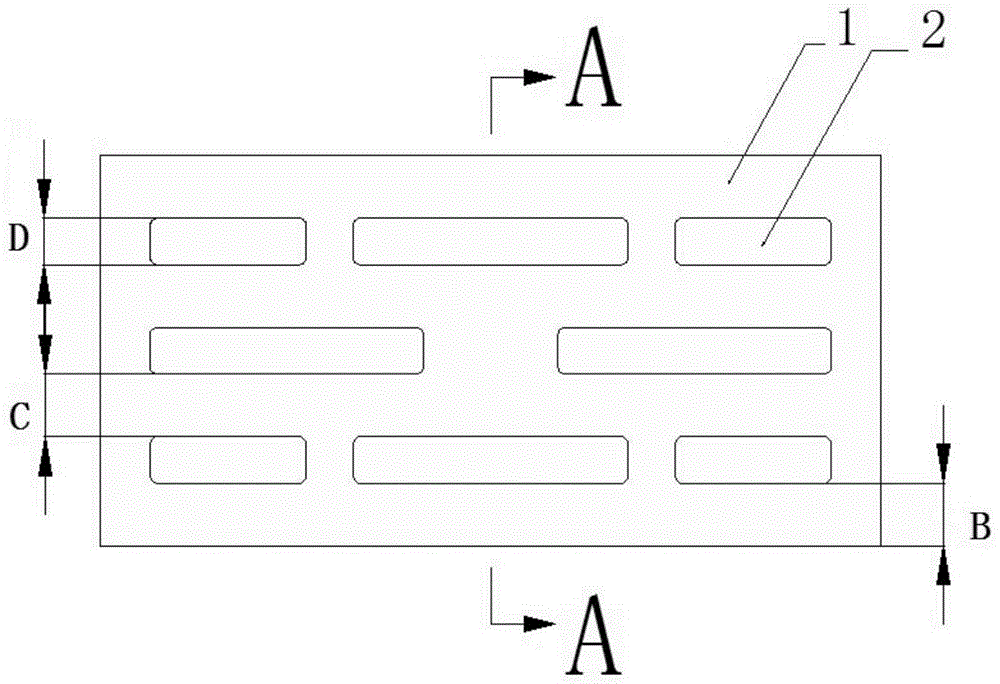

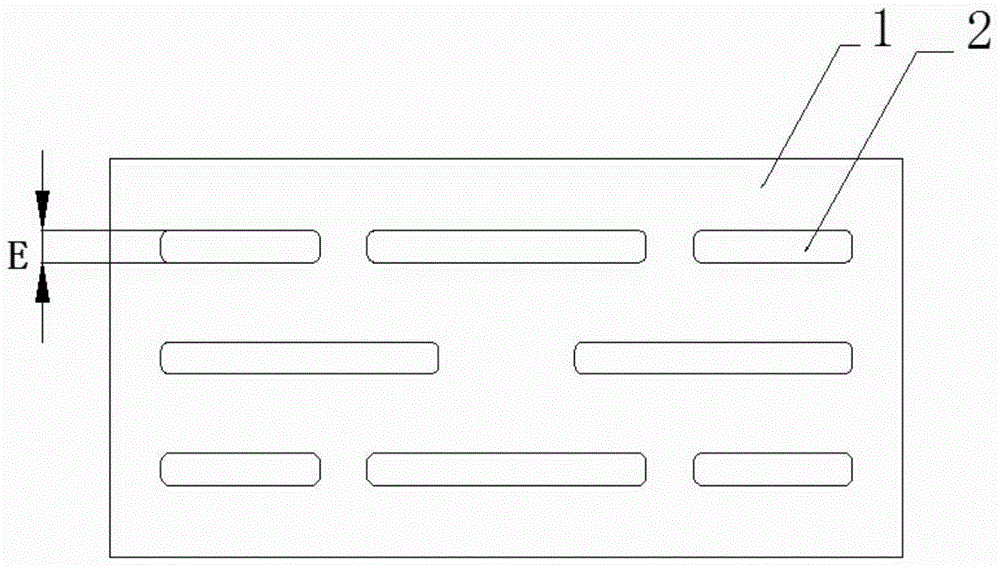

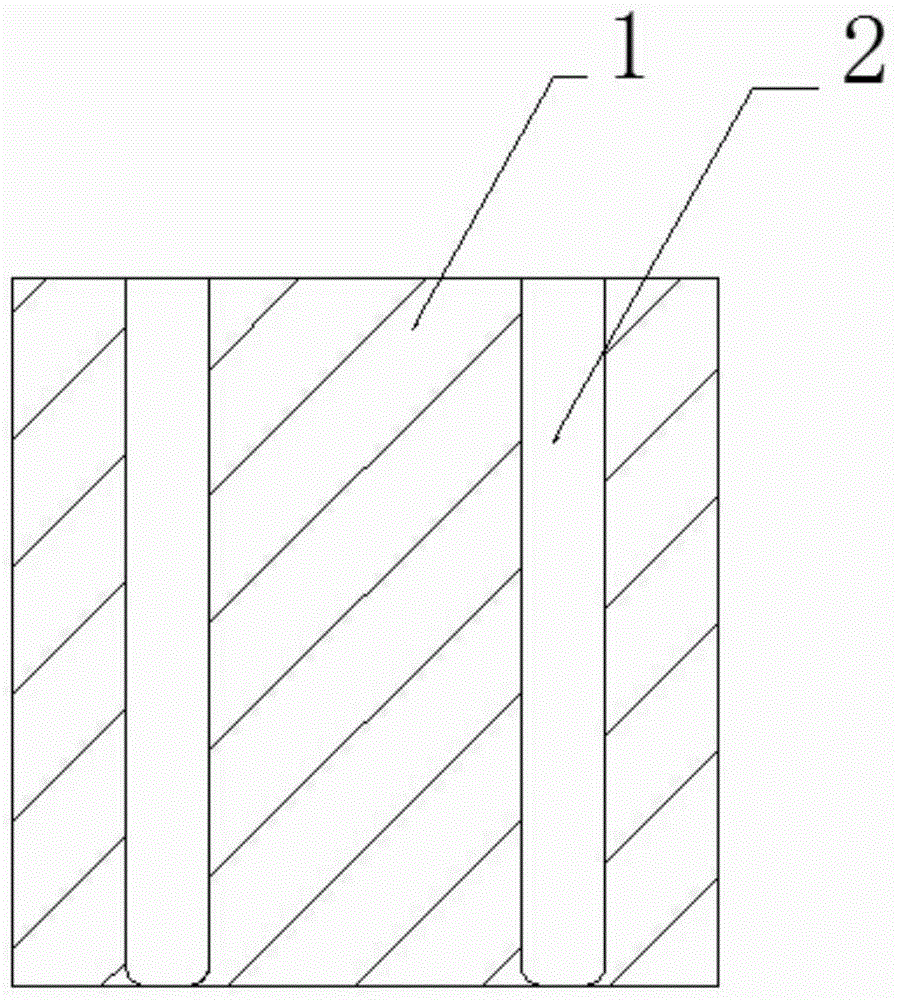

[0038] Mix the above raw materials evenly, add an appropriate amount of water, stir for 0.1h, and then transport them into the mold and punch them into blocks with the following structure: Figure 1 ~ Figure 3 As shown, the stamped block includes a block body 1, and the block body 1 is a cuboid. The block body 1 is provided with three rows of thermal insulation cavities 2, the first row of thermal insulation cavities 2 is three, the sec...

Embodiment 2

[0046] Raw materials were weighed according to the following proportions by weight: 400kg of ordinary Portland cement, 800kg of slag, 300kg of fly ash, 100kg of high-strength ceramsite, 100kg of vitrified microbeads, and 0.5kg of multifunctional admixture. Among them, the fly ash is Class II fly ash; the particle size of slag is 0.4-0.6mm; the particle size of high-strength ceramsite is 8-15mm; the particle size of vitrified microbeads is 0.5-1.5mm; CaCl 2 、Na 2 SiO3, K 2 SO 4 It is made by mixing according to the weight ratio of 0.1:0.9:1:0.4.

[0047] Mix the above-mentioned raw materials evenly, add an appropriate amount of water, stir for 0.1h, and then transport them into a mold for stamping to form a block with the structure described in Example 1. After forming, wet curing for 10 hours, normal temperature curing for 12 days, pass the inspection, and obtain cement-based Composite self-insulating high-strength energy-saving block.

[0048] After testing, the performa...

Embodiment 3

[0054] Raw materials were weighed according to the following proportions by weight: 150kg of ordinary Portland cement, 500kg of slag, 300kg of fly ash, 30kg of high-strength ceramsite, 20kg of vitrified microbeads, and 0.05kg of multifunctional admixture. Among them, the fly ash is Class III fly ash; the particle size of slag is 0.4-0.6mm; the particle size of high-strength ceramsite is 8-15mm; the particle size of vitrified microbeads is 0.5-1.5mm; CaCl 2 、Na 2 SiO3, K 2 SO 4 It is made by mixing according to the weight ratio of 0.1:0.9:1:0.4.

[0055] Mix the above-mentioned raw materials evenly, add an appropriate amount of water, stir for 0.1h, and then transport them into a mold for stamping to form a block with the structure described in Example 1. After forming, wet curing for 20 hours, and normal temperature curing for 10 days, the inspection is qualified, and the cement-based Composite self-insulating high-strength energy-saving block.

[0056] After testing, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com