Sewage treatment plant TCP/IP (transmission control protocol/Internet protocol) local area network automatic control system and method

A technology for automatic control systems and sewage treatment plants, applied in general control systems, control/regulation systems, transmission systems, etc., can solve the problems of slow variable reading speed of MCGS, unsuitable for mass production of devices, and poor encapsulation, etc. Achieve the effect of reducing production and maintenance costs, extending trouble-free service life, and reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

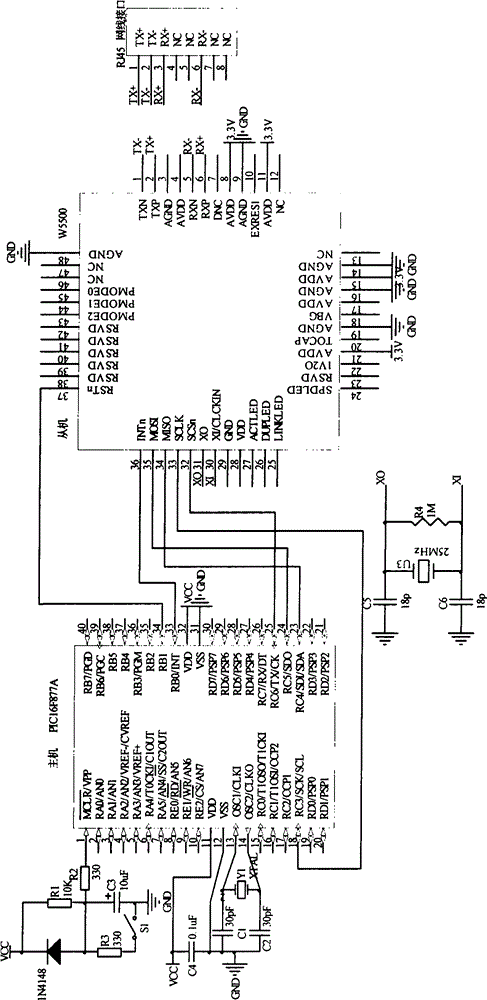

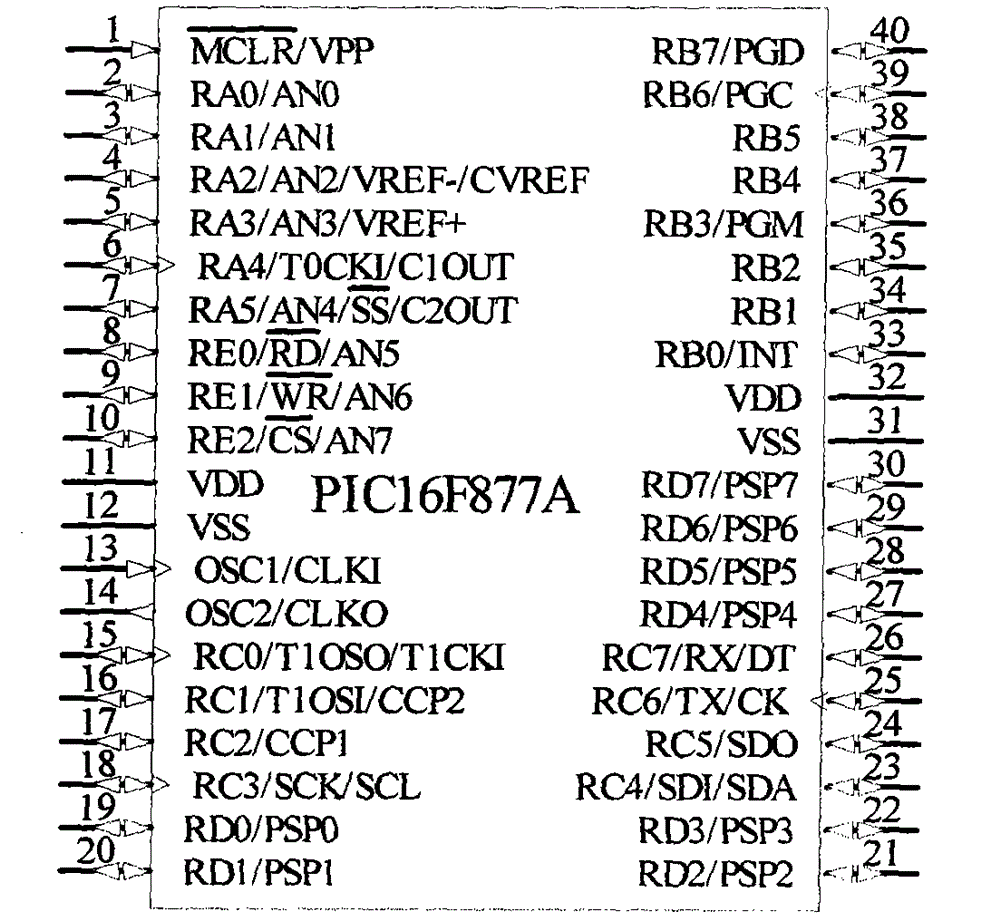

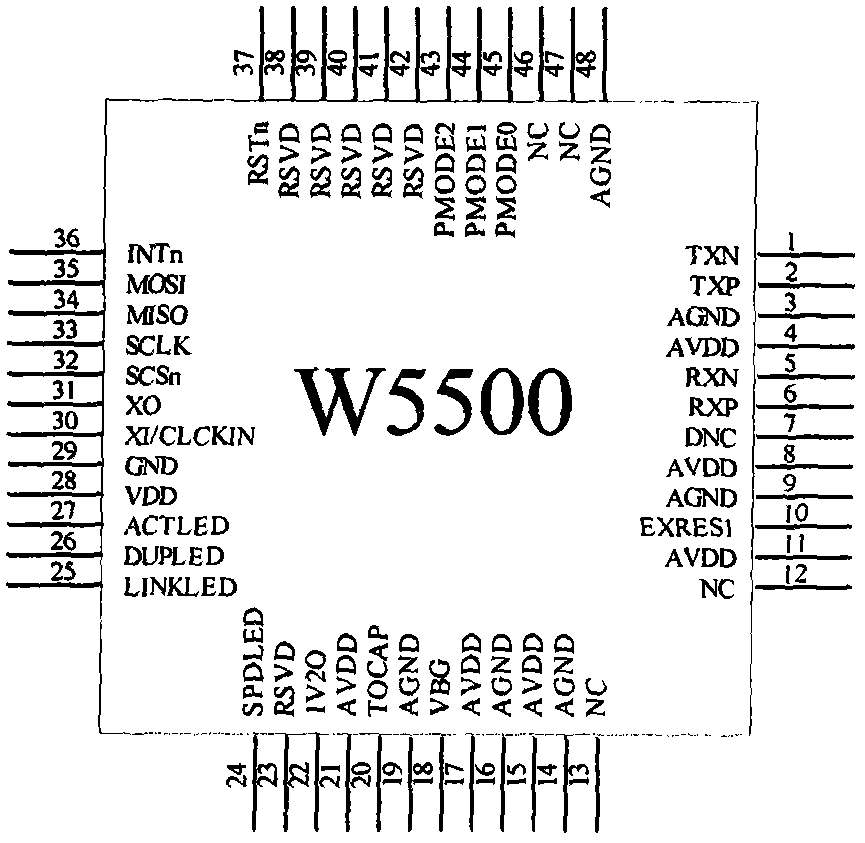

[0029] refer to figure 1 , the PIC16F877A controller implements real-time data exchange with the communication chip W5500 through the SPI communication protocol. In this system, the PIC16F877A controller is used as the main control of the SPI communication. The controller transmits the data of the relevant registers to the communication chip W5500 in real time and reads the data transmitted from the LAN. The communication chip W5500 transmits the data to the LAN through the TCP / IP protocol, and the controller that meets the data address requirements receives the data and makes a Corresponding action response, so as to realize the control and collection of digital and analog quantities of the terminal, and realize system automation.

[0030] Such as figure 2 As shown, the core chip of the control system ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com