Anisotropic conductive film, connection method, and connected body

An anisotropic, conductive film technology, applied in the direction of conductive connection, electrical component connection, conductive adhesive, etc., can solve the problems of inability to prevent wiring corrosion, insufficient adhesion, etc., and achieve excellent particle capture rate, high density Excellent compatibility and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

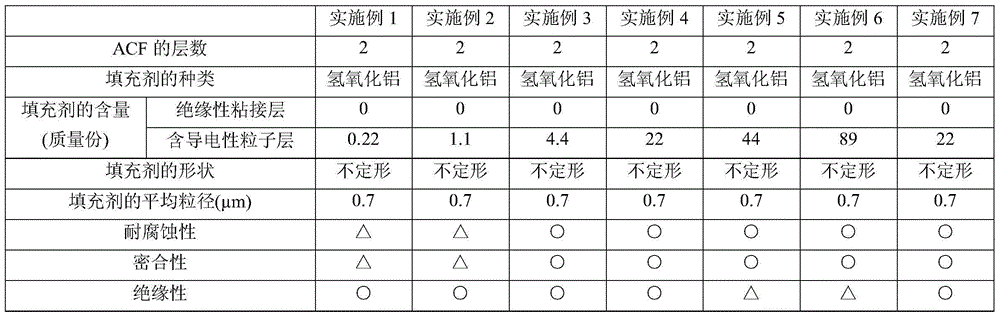

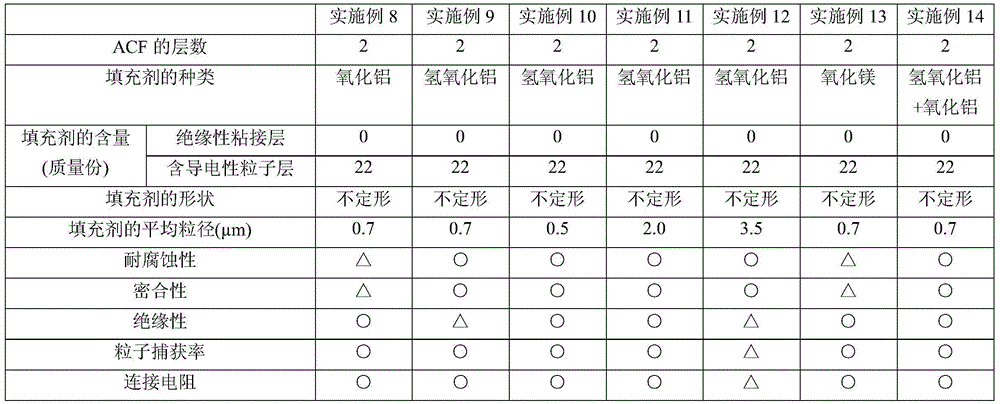

[0119] Hereinafter, examples of the present invention will be described, but the present invention is not limited by these examples.

manufacture example

[0121]

[0122] Each of the aluminum hydroxides used in the following examples and comparative examples was produced by appropriately adjusting the production method of aluminum hydroxide described in paragraphs [0019] to [0023] of JP-A-2005-162606 .

[0123] In addition, magnesium hydroxide, aluminum oxide, and magnesium oxide were produced by the same method as the production method of aluminum hydroxide.

Embodiment 1

[0125]

[0126] -Formation of conductive particle-containing layer-

[0127] 25 parts by mass of phenoxy resin (PKHH, manufactured by Pakistan Industrial Co., Ltd.), 10 parts by mass of epoxy resin (EP1001, manufactured by Mitsubishi Chemical Corporation), cationic curing agent (SI-60L, manufactured by Sanshin Chemical Industry Co., Ltd. , sulfonium salt type cationic curing agent) 10 parts by mass, silane coupling agent (A-187, manufactured by Momentive Advanced Materials Co., Ltd.) 2 parts by mass, conductive particles (AUL704, manufactured by Sekisui Chemical Industry Co., Ltd., in acrylic resin The surface of the particles is formed with Ni / Au plated film metal coating resin particles, average particle diameter 4.0 μm) 30 mass parts and aluminum hydroxide (indeterminate, average particle diameter 0.7 μ m) 0.1 mass parts using a stirring device (rotation revolution mixing machine, defoaming Rentaro, manufactured by THINKY Co., Ltd.) and mixed so as to become uniform. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com