A combined device for flue gas desulfurization and waste liquid oxidation

A combined device and flue gas technology, applied in the field of environmental treatment, can solve the problems of increased power consumption, high concentration of rich absorption liquid salt, and inability to discharge waste liquid up to the standard, saving energy consumption, improving desulfurization efficiency, and enhancing bubbling The effect of oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

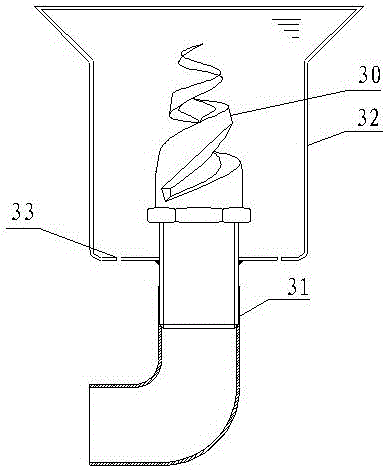

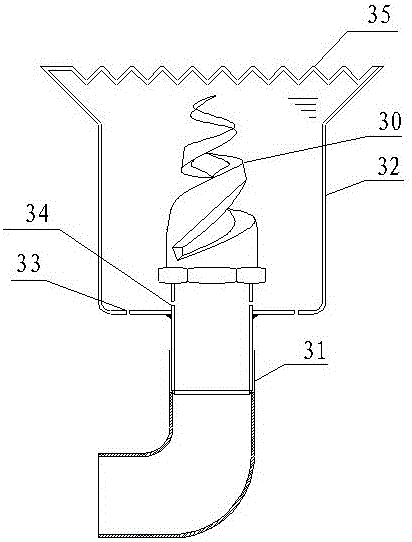

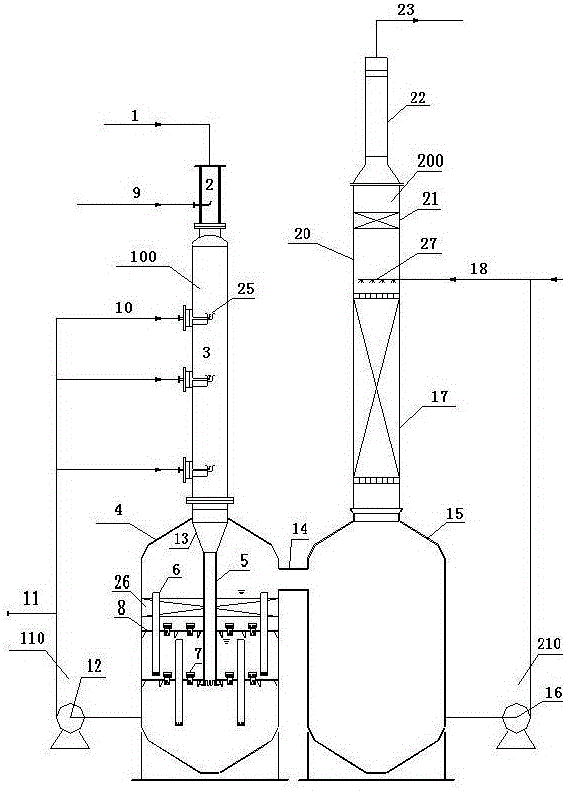

[0036] The combined device for flue gas desulfurization and waste liquid oxidation of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] Such as figure 1 As shown, the flue gas desulfurization and waste liquid oxidation combined device of the present invention includes a primary circulation oxidation system 100 and a secondary circulation absorption system 200 . Wherein the primary circulation oxidation system 100 and the secondary circulation absorption system 200 are connected through an overflow pipe 14 .

[0038] The primary circulating oxidation system 100 includes a spray tower 3, a variable diameter 13, a flue gas guide pipe 5 and a primary circulation tank 4 along the flue gas flow direction, and the primary absorbent delivery system 110 connects the primary circulation tank 4 and spray The shower tower 3 is connected, wherein the primary absorbent delivery system includes a primary circulation pump 12, a prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com