Chitosan-modified mesoporous silica-filled hybrid membrane as well as preparation and application thereof

A technology of mesoporous silica and silica filling, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve the problems of particle agglomeration, interface defects, affecting the gas separation performance of membranes, etc., and achieve a simple preparation process. , easy to operate, the effect of improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

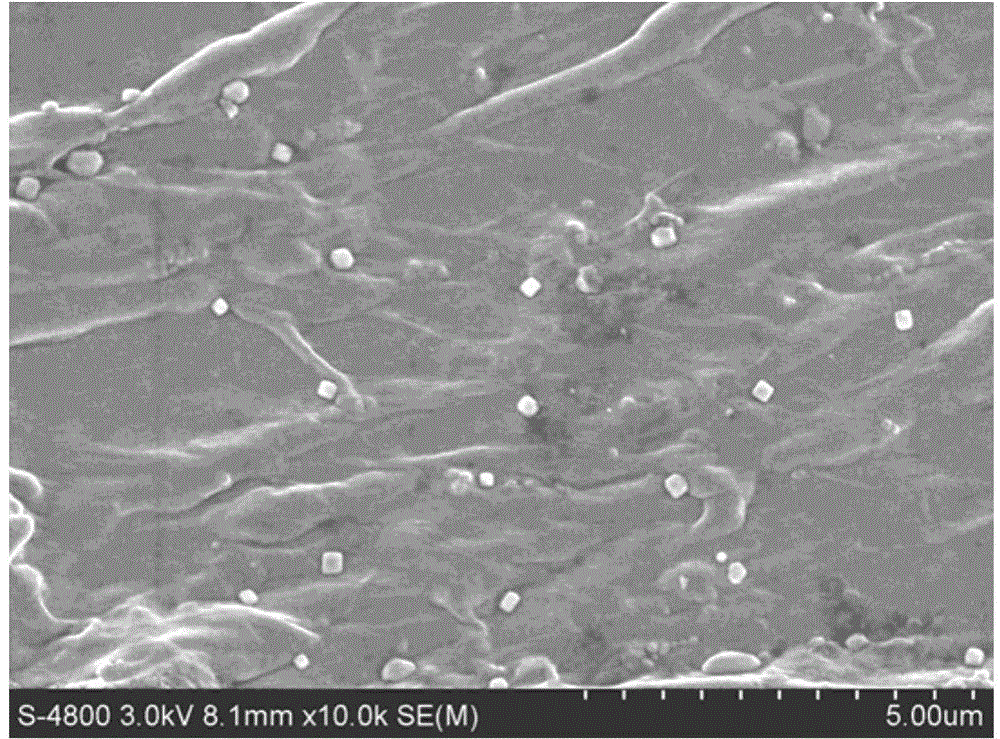

[0021] Example 1: Preparation of chitosan-modified mesoporous silica-filled hybrid membrane.

[0022] The hybrid membrane has a thickness of 85 μm, and is composed of 12.5 g of polyoxyethylene-polycaprolactam block copolymer with a mass fraction of 4% and 0.05 g of chitosan-modified mesoporous silica. In the caprolactam block copolymer, the polyoxyethylene segment accounts for 60% of the mass fraction of the block copolymer, and the polycaprolactam segment accounts for 40% of the mass fraction of the block copolymer. The preparation steps of the hybrid membrane are as follows:

[0023] Step 1, preparation of chitosan-modified mesoporous silica:

[0024] Step 1-1. Measure 480ml of deionized water, add 1.0g of cetyltrimethylammonium bromide, and stir the liquid into a homogeneous phase, then add 3.5ml of 2.0mol / L NaOH solution dropwise. After the oil bath reaches 80°C, continue to stir for 40 minutes, slowly add 5ml of tetraethyl orthosilicate dropwise, and keep at 80°C, and st...

Embodiment 2

[0030] Example 2: Preparation of chitosan-modified mesoporous silica-filled hybrid membrane.

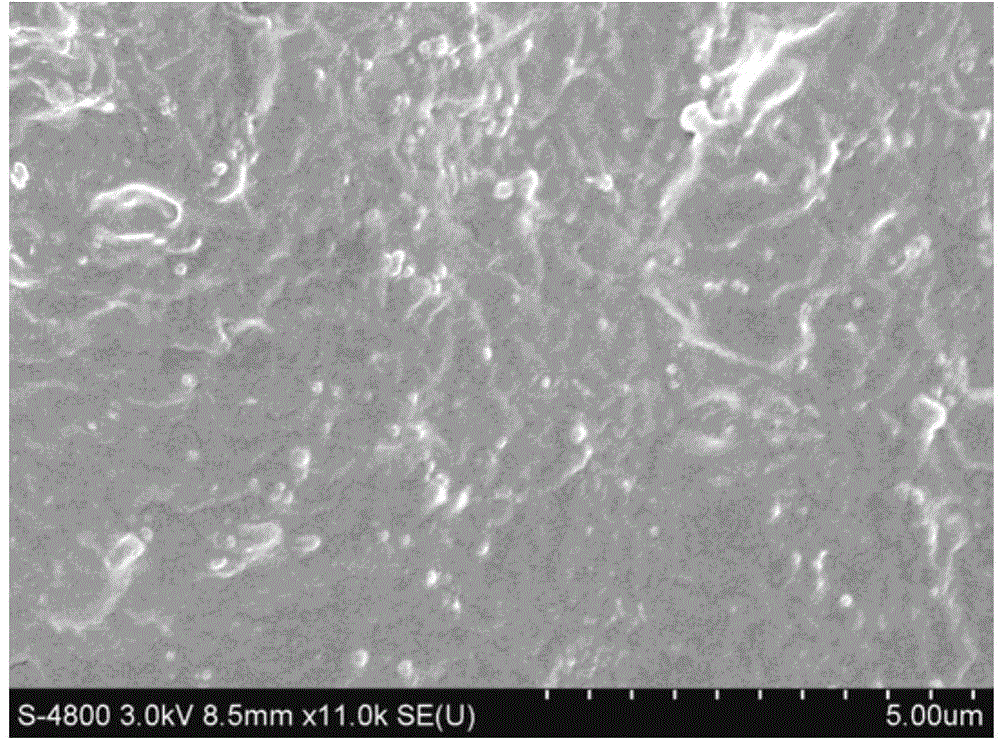

[0031] The thickness of the hybrid membrane is 89 μm, and it is composed of 12.5g of polyoxyethylene-polycaprolactam block copolymer with a mass fraction of 4% and 0.05g of chitosan-modified mesoporous silica. In the caprolactam block copolymer, the polyoxyethylene segment accounts for 60% of the mass fraction of the block copolymer, and the polycaprolactam segment accounts for 40% of the mass fraction of the block copolymer. The difference between its preparation method and the above-mentioned embodiment 1 Only: in step 3, the amount of chitosan-modified mesoporous silica was changed from 0.025 g to 0.05 g, and finally a chitosan-modified mesoporous silica-filled hybrid membrane with a thickness of 89 μm was obtained. figure 2 is the SEM sectional view of the hybrid membrane prepared in Example 2.

[0032] The hybrid membrane was used to separate CO at room temperature and 1 bar ...

Embodiment 3

[0033] Example 3: Preparation of chitosan-modified mesoporous silica-filled hybrid membrane.

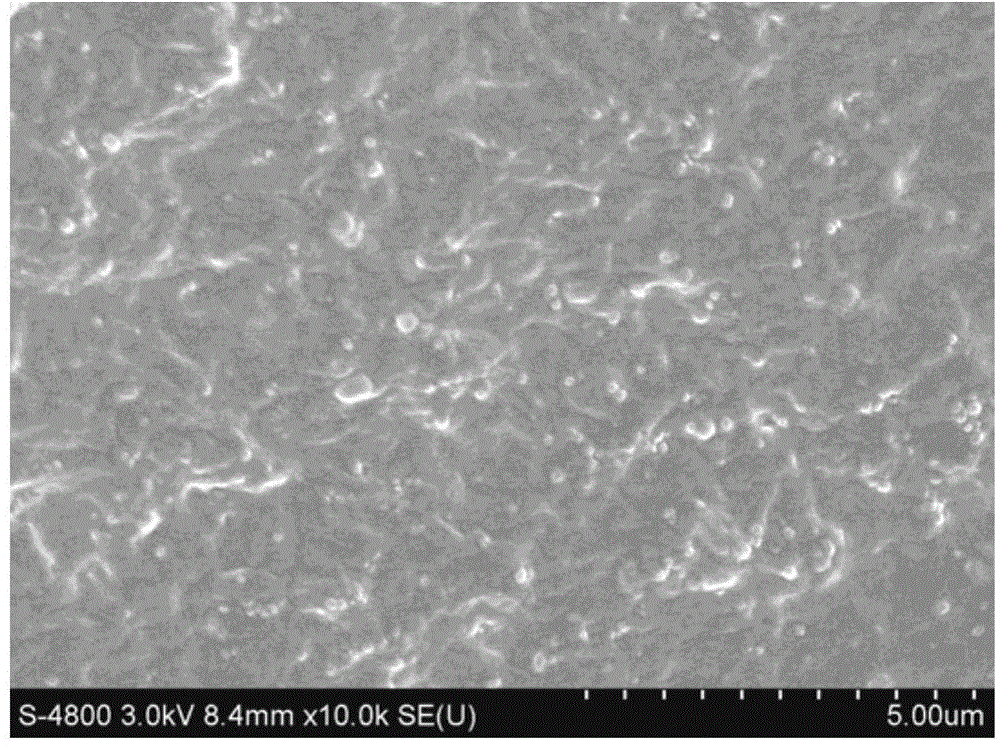

[0034] The thickness of the hybrid membrane is 96 μm, and it is composed of 12.5g of polyoxyethylene-polycaprolactam block copolymer with a mass fraction of 4% and 0.075g of chitosan-modified mesoporous silica. In the caprolactam block copolymer, the polyoxyethylene segment accounts for 60% of the mass fraction of the block copolymer, and the polycaprolactam segment accounts for 40% of the mass fraction of the block copolymer. The difference between its preparation method and the above-mentioned embodiment 1 Only: in step 3, the amount of sulfonic acid-functionalized hollow nano-hydrogel was changed from 0.025 g to 0.075 g, and finally a chitosan-modified mesoporous silica-filled hybrid membrane with a thickness of 96 μm was obtained. image 3 It is the SEM sectional view of the hybrid film prepared in Example 3.

[0035] The hybrid membrane was used to separate CO at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com