Methanal purifying agent adopting visible light photocatalysis and preparation method of methanal purifying agent

A visible light and purifying agent technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as unsatisfactory effects, low formaldehyde efficiency, and inability to efficiently utilize visible light, and improve the purification efficiency of formaldehyde. , the effect of large environmental benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 of the present invention provides a preparation method of a visible light photocatalyzed formaldehyde purifying agent, which comprises the following steps:

[0029] Preparation of powdered bismuth vanadate:

[0030] dissolving bismuth salt and chelating agent in acid to obtain a first solution; dissolving soluble vanadate in an alkaline solution to obtain a second solution; adding the second solution to the first solution to adjust the Ph value to acidity to obtain Yellow suspension: subjecting the yellow suspension to hydrothermal treatment, then performing solid-liquid separation, washing and drying the solid matter to obtain powdered bismuth vanadate. Further, the first solution is: Bi(NO 3 ) 3 ·5H 2 O and EDTA were sequentially dissolved in 2M HNO under the condition of magnetic stirring 3 In the solution, wherein the molar ratio of EDTA and Bi is 0.2:1; the second solution is: the NH 4 VO 3 Dissolve in 2M KOH under magnetic stirring; add the seco...

example 1

[0037] Step 1: Preparation of BVO powder

[0038]0.01mol Bi(NO 3 ) 3 ·5H 2 O and 0.002mol EDTA (EDTA:Bi=0.2:1) were successively dissolved in 15ml 2M HNO under the condition of magnetic stirring 3 , to obtain the first solution; 0.01mol NH 4 VO 3 Dissolve in 10 ml 2M KOH under magnetic stirring to obtain a second solution. Then, under the condition of magnetic stirring, the second solution was added dropwise to the first solution, with 2M KOH or 2M HNO 3 Adjust pH=4 to obtain a yellow suspension.

[0039] Afterwards, the yellow suspension was transferred to a hydrothermal kettle (volume 100ml) and sealed, and placed in an electric blast drying oven at 160°C for 20h. Finally, the suspension in the hydrothermal kettle was centrifuged, washed three times with deionized water and once with absolute alcohol, and then dried in an electric blast drying oven at 60°C to obtain a yellow powder.

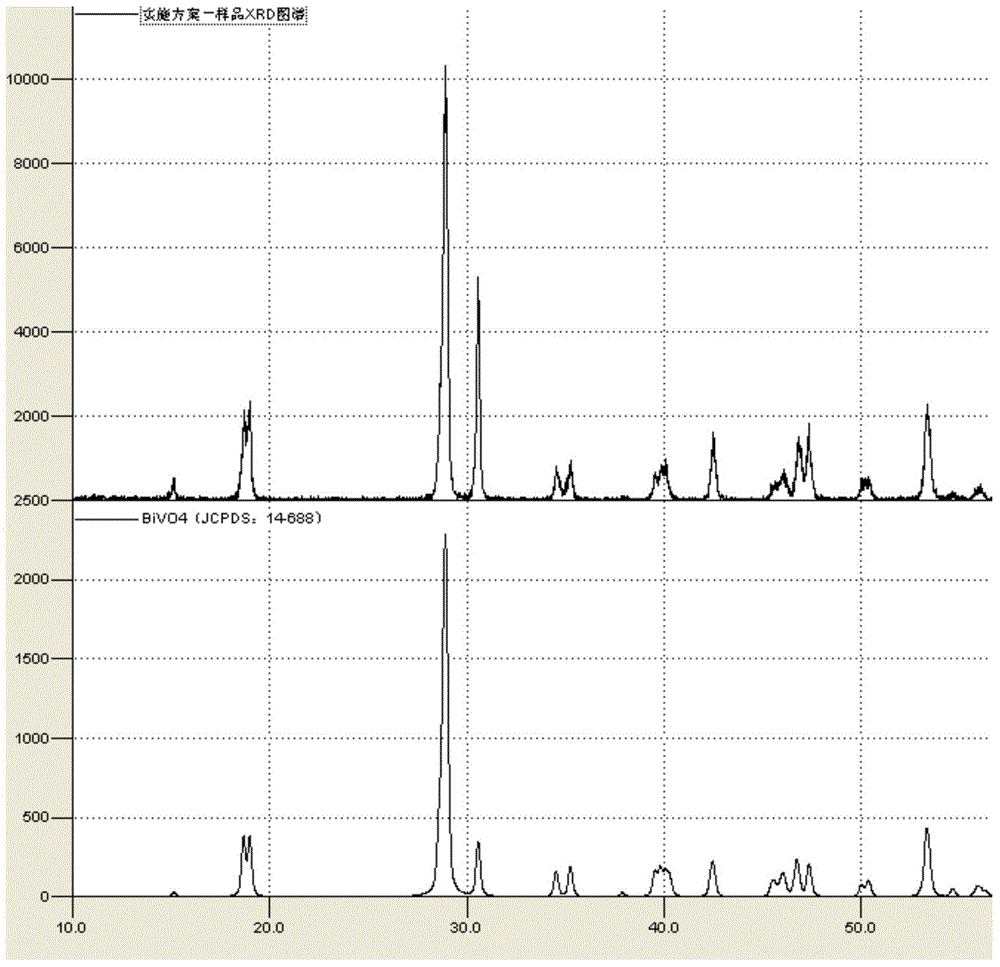

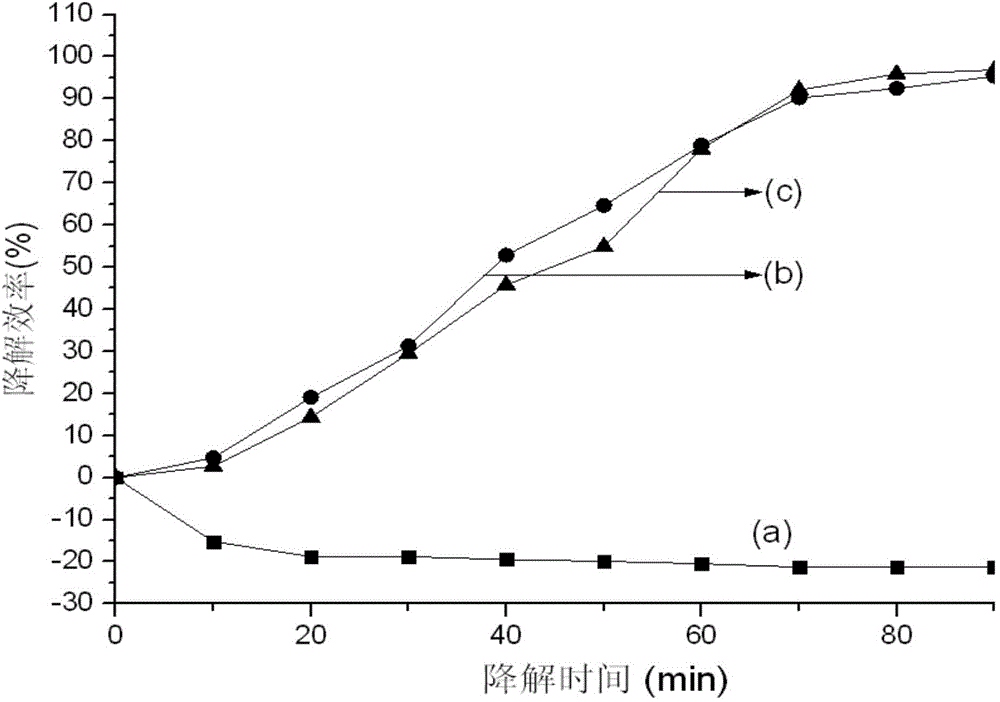

[0040] Through the XRD pattern ( figure 1 ) It can be seen that the yellow powder ...

example 2

[0047] Step 1: Preparation of BVO powder

[0048] 0.01mol Bi(NO 3 ) 3 ·5H 2 O and 0.005mol EDTA (EDTA:Bi=0.5:1) were successively dissolved in 15ml 2M HNO under the condition of magnetic stirring 3 , the resulting solution is named A solution; 0.01mol NH 4 VO 3 The solution obtained by dissolving in 10 ml 2M KOH under the condition of magnetic stirring is named B solution. Then, under the condition of magnetic stirring, the B solution was added dropwise to the A solution, with 2M KOH and 2M HNO 3 Adjust pH=7 to obtain a yellow suspension.

[0049] Afterwards, the yellow suspension was transferred to a hydrothermal kettle (volume 100ml) and sealed, and placed in an electric blast drying oven at 200°C for 10 hours. Finally, the suspension in the hydrothermal kettle was centrifuged, washed three times with deionized water and once with absolute alcohol, and then dried in an electric blast drying oven at 60°C to obtain a yellow powder.

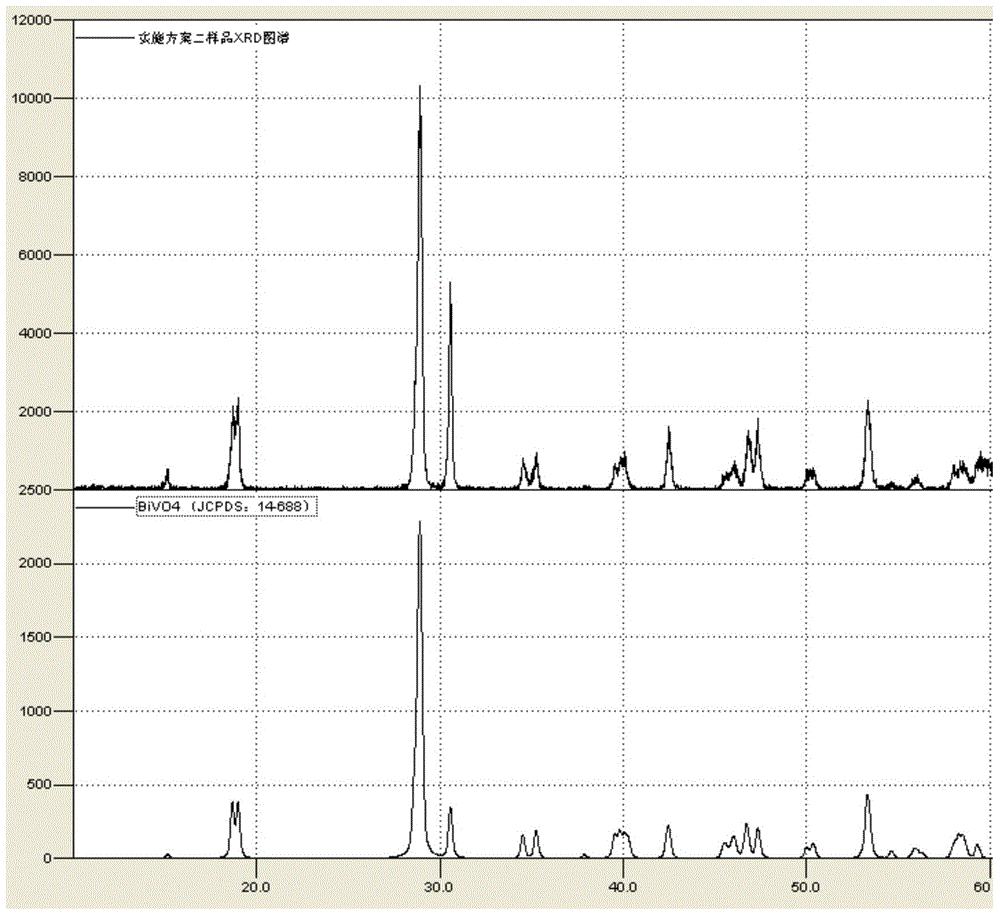

[0050] Through the XRD pattern ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com